By: Giles Gaskell

We have significant improvements in many areas including:

• Innovative New Hardware Types

• Hardware Data Capture Speeds

• Optical and Mechanical Accuracy

But it is the last two that have the largest impact on our ability to accurately measure and create 3D Images and 3D Scans. Both are related to the massive increase in computer processing speed that has paralleled the other developments in 3D scanning:

• Point Cloud Post Processing Software

• PC Hardware Processing Speed

With our new hardware innovations we can get millions of points today when we scan a physical object. Our ability to process those points has come along tremendously in the last 2 decades.

But no matter how many points our machines can get, we have to be able to process the data.

In the past, even if we’d been able to generate the data we couldn’t have processed it.

In fact with today’s best CT machines, like Wenzel’s exaCT, the processing speed is still the upper limiting factor. In other words, the machines have an accuracy, completeness and precision that exceed our ability to process all the data points we can collect.

Today’s Modern Metrology Systems include two main machine classes:

1. Conventional Measurement

These are your Coordinate Measuring Machines.

CMMs are the metrological workhorses. Today’s technology for CMMs relies on the precision and intrinsic accuracy of traditional craftsmanship like you find in Wenzel’s all granite CMMs.

And couples that with the latest touch probes, contact scanners and software that allows us to measure from very small to gears that measure 30 feet in diameter and entire cars.

Modern CMMs use very advanced software in combination with the traditional, highly accurate scanners. Only traditional CMMs with touch probes are accurate enough to measure machined parts, body panels, crankshafts, camshafts, or gears.

If you’re measuring parts like this, with geometric shapes and in need of high accuracy there is no other game in town than a sturdy, reliable granite CMM and Renishaw Probe. Even if there were an accurate non-contact solution there is nothing to be gained by using it.

Non-Contact Scanners – 3D Scanners

In the rest of the series, we’ll lay out the various decision points that need to be considered when investing in 3D Imaging technology and non-contact scanners.

The first thing we’ll look at is whether one wants or needs to use a Handheld 3D Scanner or a Machine-Mounted 3D Scanner. We’ll cover the major Pros and Cons of each and that should help with your 3D Scanner buying decision tree.

My first experience in the field was with handheld 3D scanners, they’ve come a long way since:

Handheld 3D Scanners

Pros:

– Maximum versatility

– Real-time registration

– Totally Portable

Cons:

– Operator dependent results

– Tiresome for large or repetitive jobs

– Relatively inaccurate

Machine Mounted 3D Scanners

Pros:

– Highly accurate +/- 0.0005”

– Repeatable

– Automated

– Ordered data

Cons:

– Longer Set up time

– Non-portable

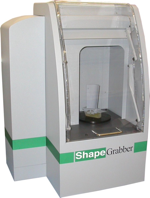

Though they are not portable machine mounted 3D Scanners can configured in many different ways since they are often mounted on traditional CMMs. You can attach them to a shop floor coordinated measuring machine just as easily as you can attach them to a gantry horizontal arm machine.

There are also smaller and more portable machines that can easily fit in a testing lab. Or, in the case of our exaCT machines they can even fit on a desktop workstation.

Being mounted and fixed their measurements are 100% repeatable. There is no “operator” discrepancy so are highly accurate like their traditional CMM cousins. The downside of course is the parts must go to the machine just like traditional CMMs. And you certainly can’t put it in the trunk of your car and take it with you.

Being mounted and fixed their measurements are 100% repeatable. There is no “operator” discrepancy so are highly accurate like their traditional CMM cousins. The downside of course is the parts must go to the machine just like traditional CMMs. And you certainly can’t put it in the trunk of your car and take it with you.

About Wenzel America

Wenzel America Ltd. is a wholly owned subsidiary of Wenzel Group of Germany. Contact Wenzel America by phone at 248.295.4300, email us[email protected] or subscribe to our newsletter.

About Giles Gaskell

Giles Gaskell has been involved in industrial 3D Imaging and 3D Scanning since it’s earliest beginnings. He founded the first distribution company for hand-held 3D Scanners in the UK and then Italy. Since arriving in the United States in 2005 he has continuously worked in the 3D Scanning an Imaging arena in business development and education. Giles is 1 of 3 Advisors North American advisors to SME’s RAPID show which is focused on 3D Printing and Additive Manufacturing. Since 2010, Mr. Gaskell has been the Applications and Sales Manager for 3D Imaging products at Wenzel America.