First, let’s take a look at what a fixture is from a Wikipedia article on the subject:

What is a fixture?

A fixture is a “work-holding” or support device used in the manufacturing industry.[1][2] Fixtures are used to securely locate (position in a specific location or orientation) and support the work, ensuring that all parts produced using the fixture will maintain conformity and interchangeability.

What does a fixture do?

Using a fixture improves the economy of production by allowing smooth operation and quick transition from part to part, reducing the requirement for skilled labor by simplifying how workpieces are mounted, and increasing conformity across a production run.[2]

Here is the video to WENZEL’s Tuesday Tech Tip featuring all you need to know about fixturing with the experts form Phillips Precision.

How is a fixture different from a jig?

A fixture differs from a jig in that when a fixture is used, the tool must move relative to the workpiece; a jig moves the piece while the tool remains stationary.[3]

5 Questions to Consider Before Fixturing

- How many parts are you going to measure?

- Is this just a one time run, or is this a part that will be measured over weeks, months or even years?

- How accurate does my measurement have to be

- What type of repeatability are you looking for? Who will be measuring the part?

- Will the part be measured by the quality personnel or will it be operated by a machine operator as part of a cell?

What are the different types of fixturing solutions?

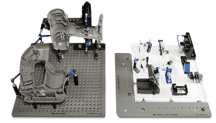

Engineered Fixturing Solutions

Recently, a GM plant in Flint, Michigan built it’s millionth 1.4 liter engine. Considering the number of operations that are run on head, blocks and cranks, you have to assume that the fixturing used to measure the various machining operations are robust. Those fixtures are most likely engineered specifically for the part and/or operation. In most cases it would be desirable to have one fixture for all the operations on a part.

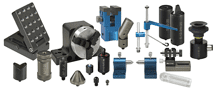

Modular Fixturing Solutions

Unlike GM, most manufacturers are not running a million parts. Maybe you are running off as few as thirty parts to prove a capability to a customer. In this case, it doesn’t make sense to pay for an engineered fixture due to cost and timing. In these cases, modular fixturing offers a great solution.

Modular fixturing allows you to buy either a standard plate size or custom. You then pick and choose the additional pieces to attach to the plate that create a fixture that supports and constrains your specific part. The modular system allows you to build a custom fixture to meet your needs. You can even keep the setup and buy new modular components and plates to make fixtures for all of your parts.

After you’ve decided between Engineered or Modular, now what?

It is important to think about how you are going to hold the part, so that you can access the datums andhave access to the features to be considered. With an engineered solution someone else will have done that for you. In some cases you can re-use the fixture that was engineered to hold the part in the manufacturing process for the measurement as well.

When you create your own modular fixture you have to assemble it so all needful areas are accessible for measurement. Ideally, you construct the fixture so the part is in a “free state” with no clamping force on the part.

When you create your own modular fixture you have to assemble it so all needful areas are accessible for measurement. Ideally, you construct the fixture so the part is in a “free state” with no clamping force on the part.

It’s a balancing act between keeping the part motionless and also not constraining in such a way that the part is deformed during the measuring process.

If your parts are small, or if your CMM is big enough, you may be able to nest parts so that you can stage several parts on a single plate and press one button to measure them all.

Other fixturing situations

Car Body, Aircraft Body parts offer unique fixturing challenges:

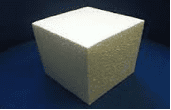

As do Vision Systems and CT – which need to allow the part to be “seen.” This could be visually, or in the case of CT, the fixture must be of a material that will allow the x-rays to pass though with very little energy loss.

As do Vision Systems and CT – which need to allow the part to be “seen.” This could be visually, or in the case of CT, the fixture must be of a material that will allow the x-rays to pass though with very little energy loss.

When all else fails…there’s always duct tape

Sometimes, you just need to do a quick check. Maybe it’s a one-off or perhaps you are trying to settle a dispute. In these cases, you can create fixtures from a number of different items including: putty, double sided tape, v-blocks, clamps or hot glue guns.

Sometimes, you just need to do a quick check. Maybe it’s a one-off or perhaps you are trying to settle a dispute. In these cases, you can create fixtures from a number of different items including: putty, double sided tape, v-blocks, clamps or hot glue guns.

Even threading some stops into the bolt holes on the granite plate and pushing the part against them could work.

Even threading some stops into the bolt holes on the granite plate and pushing the part against them could work.

And as we all know, duct tape can fix anything.

And as we all know, duct tape can fix anything.

The best way to explain fixturing and what it could mean to your business is to watch the Tuesday Tech Tip with Mariano Marks and Allan DeLisle from Phillips Precision.