Recently, I was reminded by a friend of mine about going to the gemba*. There was a time in both of our pasts, that this held a particular prominent place in our mind sets. We were on teams working on A3 reports for the company we were employed at. The gemba was this place where we could go to actually see where the value was created in the processes we were working on. For a salesperson, that is visiting a customer, and for most people with customer facing jobs that is the place where they interact with the customer.

In lean manufacturing that is the practice of going where the action is. When I was serving in the armed forces, that meant getting out from behind my desk, or office and going out onsite. In any case, this gemba walk helps to reconnect you to the processes that you own. At one of my jobs, it was going out to Point Vicente Light, interacting with the caretakers and doing maintenance on the light itself. There is a definite art to the mix between being out there and staying put. Accomplishing the myriad of tasks that managing a crew, team, office, or territory can be daunting, but should not prevent gemba walks.

A great majority of research and information can be performed before one needs to do this gemba walk. Researching the latest best practices, trends, apps, equipment, etc should start first, and in my opinion, is supremely important. Eventually, you have to test assumptions, observe what’s really happening and verify the data that you have been reviewing.

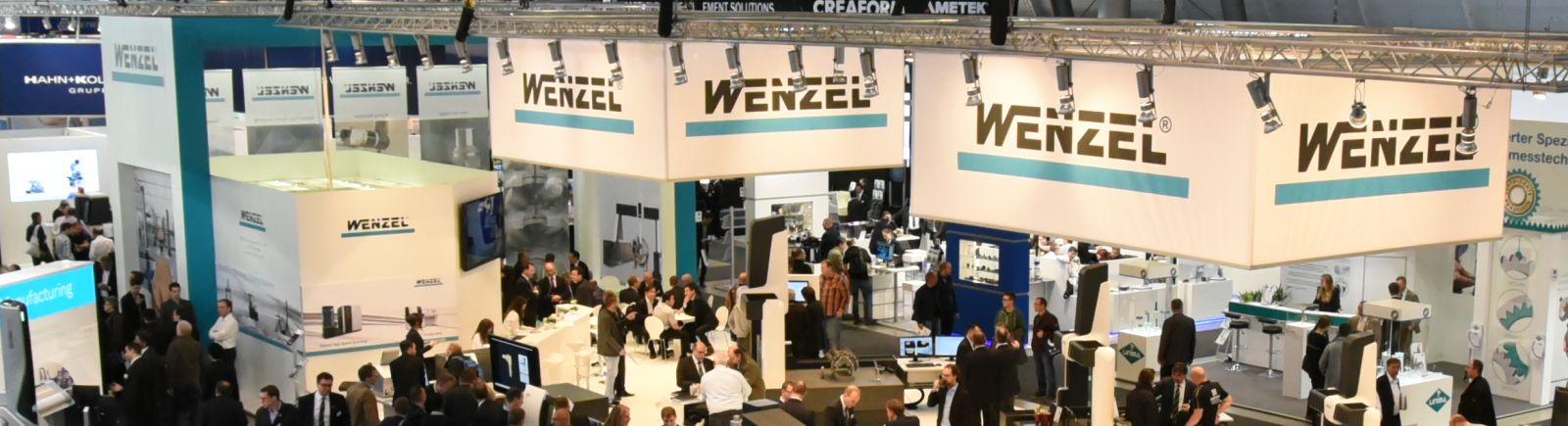

For people in the quality field, which is a mature field, this starts in some of the following ways. Observing the quality practices and how they are actually performed in your shop, randomly auditing your processes, reading technical journals, blogs etc. One way to get ahead of the curve, to get an over the horizon view of what’s next, is by going to a SME event or to an industry trade show.

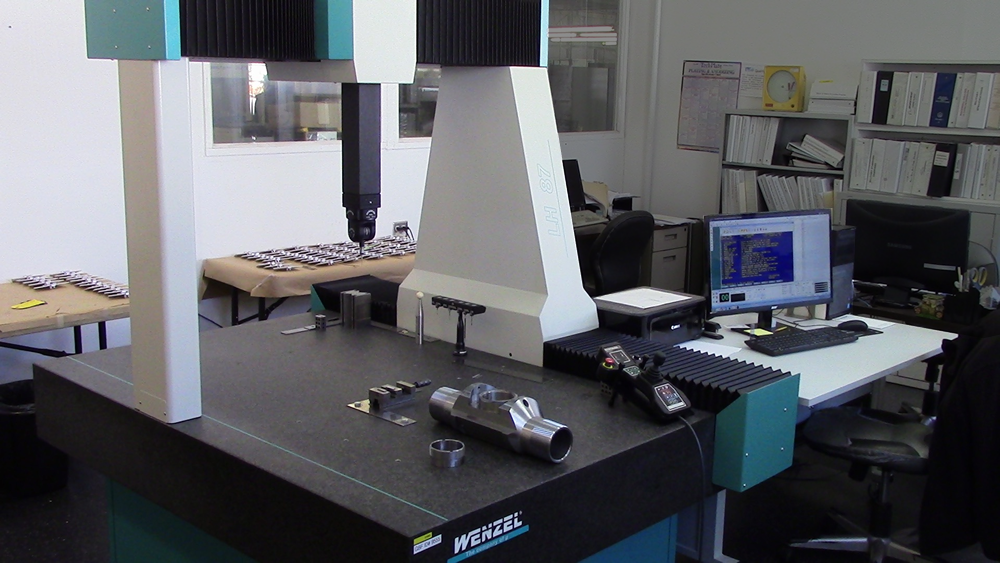

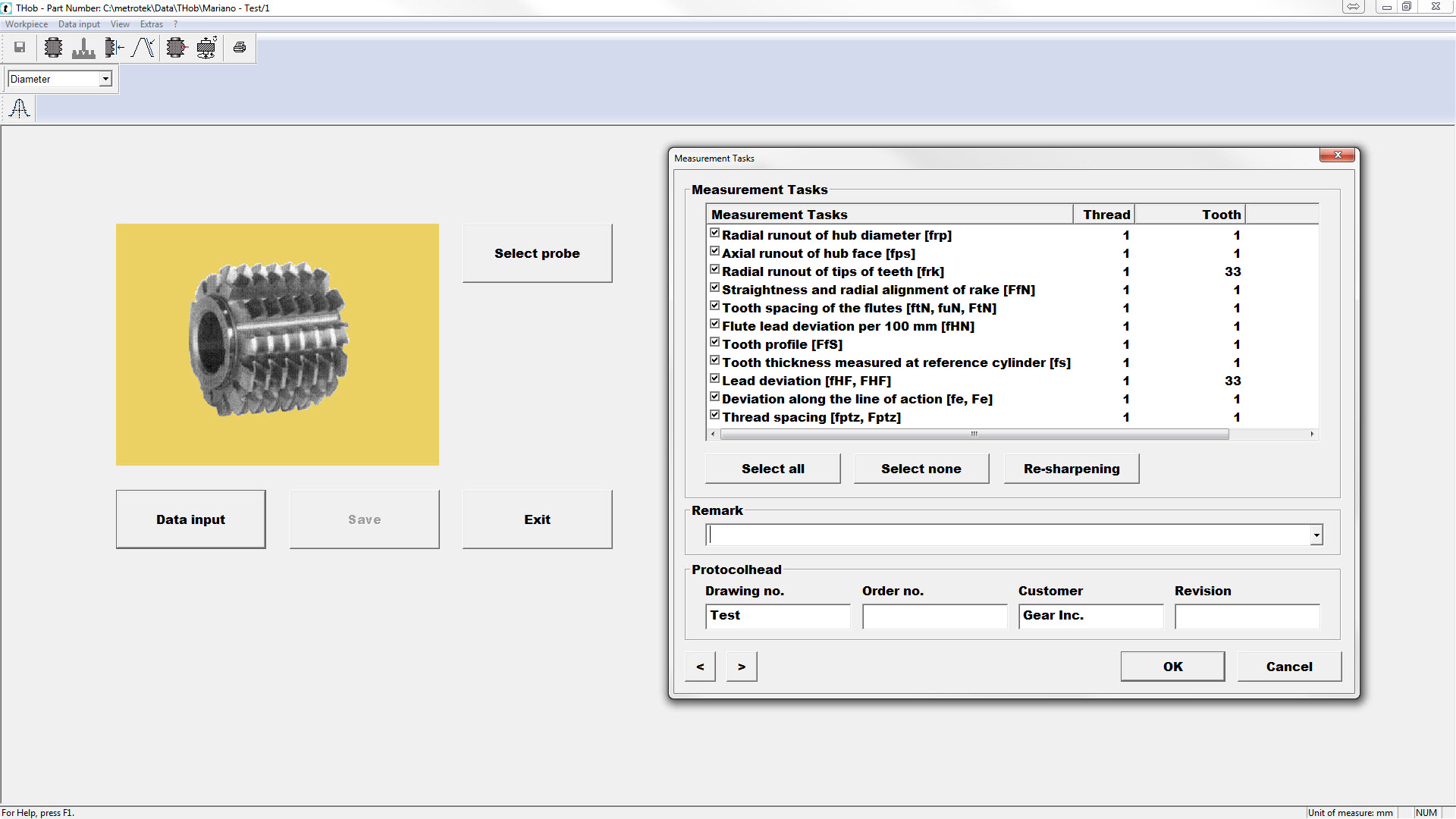

Take the example of gear measurement technology. Sure you have read and subscribed to the various magazines, but to get a chance to kick the tires on gear checking machines, find out who is going to support you, how easy the software is to use, etc, only happens on this type of trade show gemba walk.

From a quality suppliers view, I would prefer you to come visit our office, let us demonstrate our capabilities on your part. At a trade show, you, the end customer have a great opportunity to ask questions of all the particular vendors in real time. Can the OEM demonstrate the measurement of you part, sight unseen and provide you the metrology answers you need? Is the software really easy so you can actually measure your part in the booth or does it still require the booth personnel to do it?

These over the horizon looks at what’s new, put you in a much better position when you recommend technology for adaptation in your company. Come check us out at CMTS 2017 Booth #3507, the Quality Show Booth #1027, and the Gear Expo 2017, Booth #206.