The promise of the future has always been alluring, flying cars and the like. In metrology, which is a rather mundane endeavor, the promise of the future has been non-contact measurements. The idea is that you place your part in a measuring volume, press a button and voila, you get measurements that you can use.

The promise of the future has always been alluring, flying cars and the like. In metrology, which is a rather mundane endeavor, the promise of the future has been non-contact measurements. The idea is that you place your part in a measuring volume, press a button and voila, you get measurements that you can use.

In some cases that future is now. For example, take Industrial Computed Tomography (ICT), in some cases you CAN put a part inside the machine and press a button and get results. There are, however, some things to consider before you dive head first into ICT.

How does ICT work?

X-rays slice through the part which is on a rotary table and those X-rays are captured on a detector. The detector records the x-rays as a gray scale.

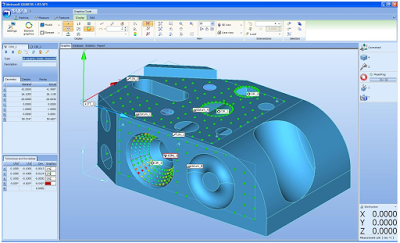

These 2D images are reconstructed into a 3D image, the individual points becoming 3D pixels or voxels.

These voxels form a point cloud which can then be output into a .STL file format or be used for NDT or dimensional measurements.

Here be dragons (or Chemistry and Physics)

The first questions customers usually ask is, “Will it measure my part?”. In response to that, we generally ask two questions, “How big is it?” and “What is it made of?”.

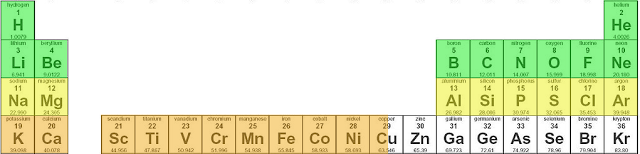

A colleague of mine in Germany, recently gave us a presentation where he explained the CT in relation to the periodic table. This cast the whole question of “can you measure my part” in a whole new light. In general, ICT shines when working with elements up to element 10. It’s good with elements up to element 18. Element 29, CU, Copper is a demarcation line.

It is not prohibitive, but you need to start considering thickness, the material composition of the part, the various multiple materials etc. The amount of power needed to “punch” through the denser materials, the time it takes to scan the part all become variables to be considered.

In the cases of denser materials or multi materials, I think the best course of action is to actually try it and see if it works for your part.

Simplest way to see if ICT works for you and your parts

The great thing that we offer is a free scan to see how our systems work with your parts and materials. If getting us a sample part to measure requires a NDA, (Non-Disclosure Agreement) we can execute this in fairly short order.

It doesn’t cost you anything but the shipping to get results on one of your parts. It is only a matter of sending the parts to Wenzel America and for us to provide you with the results via a Web Meeting for fastest turnaround.

![]() POC: Giles Gaskell

POC: Giles Gaskell

ADDRESS: Wenzel America 28700 Beck Rd. Wixom, MI 48393

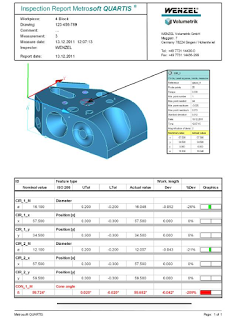

ICT is great for non-destructive testing (NDT), but the magic that we spoke of earlier, the call to the future, was being able to have your part measured inside and out with features measured to nominals or a nominal to CAD comparison. Using a Wenzel CT will enable you to get reliable measurement results. In this case, the report you will receive will include the display of some of the NDT elements and a metrology report in either a traditional form, or via a graphical representation.

The future is now for you to see all of your part. Whether it is an assembly that you are checking for proper fit, or if you are checking for the dimensional data on some internal feature, send us your part now.

The future is now for you to see all of your part. Whether it is an assembly that you are checking for proper fit, or if you are checking for the dimensional data on some internal feature, send us your part now.