July 2017 will mark the end of my first year at Wenzel. I thought it would be nice to reflect on my journey and bring you along. I was hired during a time of transition at Wenzel America. The company had grown on a solid foundation to a point where evolution was inevitable. I was lucky to be a part of the Wenzel family as we grew and expanded rapidly.

The early changes included new positions that were created to continue the momentum we had built. The first was a gear specialist (Mariano Marks) to provide new and existing customers support beyond what could be achieved with just a sales staff. The second was the division of CT Services (Giles Gaskell), Application Support (Stuart Nichols) and Programming/Service Support (Alex Aull). By having three teams and three team leaders each group can specialize to provide quicker and focused back up for the sales staff and faster turnaround time for inspections and demos. These three teams have been crossed trained so collaboration is efficient at all staffing levels. The third new position is our Director of Styling Solutions, Mike Yaremchuk. Wenzel recently released a new line of clay milling equipment for the styling industry. Mike will help us take these product to the US market and

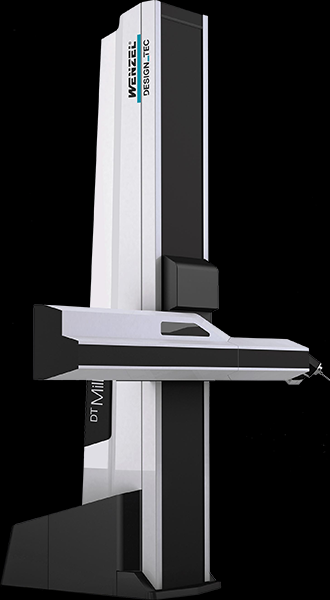

The early changes included new positions that were created to continue the momentum we had built. The first was a gear specialist (Mariano Marks) to provide new and existing customers support beyond what could be achieved with just a sales staff. The second was the division of CT Services (Giles Gaskell), Application Support (Stuart Nichols) and Programming/Service Support (Alex Aull). By having three teams and three team leaders each group can specialize to provide quicker and focused back up for the sales staff and faster turnaround time for inspections and demos. These three teams have been crossed trained so collaboration is efficient at all staffing levels. The third new position is our Director of Styling Solutions, Mike Yaremchuk. Wenzel recently released a new line of clay milling equipment for the styling industry. Mike will help us take these product to the US market and  provide an industry expert to all Wenzel customers.

provide an industry expert to all Wenzel customers.

Besides these new positions, Wenzel has also expanded the service and programming teams. Service has hired and trained 4 new calibration specialists and one new Gear Calibration specialist. This extra capability has allowed us to respond faster for our customers and offer more specialisation relating to Gear, CORE, CMM and Styling product lines. We also have a new CORE/REVO programmer who adds extra capabilities for training, demos and onsite programming.

Another big change in the applications department has been adding additional levels of training. We now offer Aukom training classes. These classes are “brand free” and cover the basics of metrology, and even GD&T. We also have new training materials for OpenDMIS and additional instructors to cover it. We have more programmers to provide onsite training as well. The final enhancement is creating new partnerships to get Quartis and OpenDMIS into many more users hands.

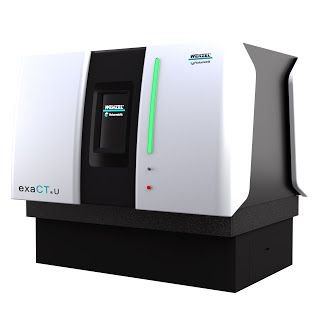

Products have been upgraded as well. I have witnessed the launch of a new CT machine that is customizable to fit the customer’s needs. The new styling mills are faster than any others in the industry and will fit in spaces too small for others to fit. We have released new sizes of gear measurement machines to better align with the customers wants.

We also introduced an Intelligent Machine Interface that allows our customers to receive data relating to the program running, critical diagnostics and machine uptime. Stay tuned for more.

This in the next step for Wenzel to be a leader in industry 4.0. It is very exciting that most products have a new look and better technical specifications to continue our trend towards market dominance.

What I have learned this past year is twofold. The first is Wenzel is a rapidly expanding company that looks at every opportunity to better serve its markets. We are constantly evolving and building on the strong foundation that was formed here before my time here.

The second thing, and the one that keeps me here at Wenzel is truly a family company. Yes we are family owned by the Wenzels but more than that, we try to be there for our customers and our community. We donate our time to help students. We participate in community activities and charities. The people that work here are all focused in one direction… Up.