More often than not, Wenzel’s WGT is described as a “gear-checking machine”. While it’s main operation is to inspect spur and helical gears, especially since that is the default software it comes with, it is much more than that. The breadth and depth of products that the WGT series can inspect is quite extensive. This means that this dedicated inspection machine might actually be versatile enough to meet your quality needs with accuracy and precision. Here are the tasks it can perform with ease each as intuitive as the last.

Beveloid gears – Although not quite bevel gears, these special gears are measured just like a regular except all you’ll have to let TGear know is the small angle that the gear tapers. That’s all!

Beveloid gears – Although not quite bevel gears, these special gears are measured just like a regular except all you’ll have to let TGear know is the small angle that the gear tapers. That’s all!

Missing teeth and interrupted leads – Do you have part of a gear? Is there room for an O-ring in the middle of your gear? No sweat. The WGT has visual representation for programming these distinct features.

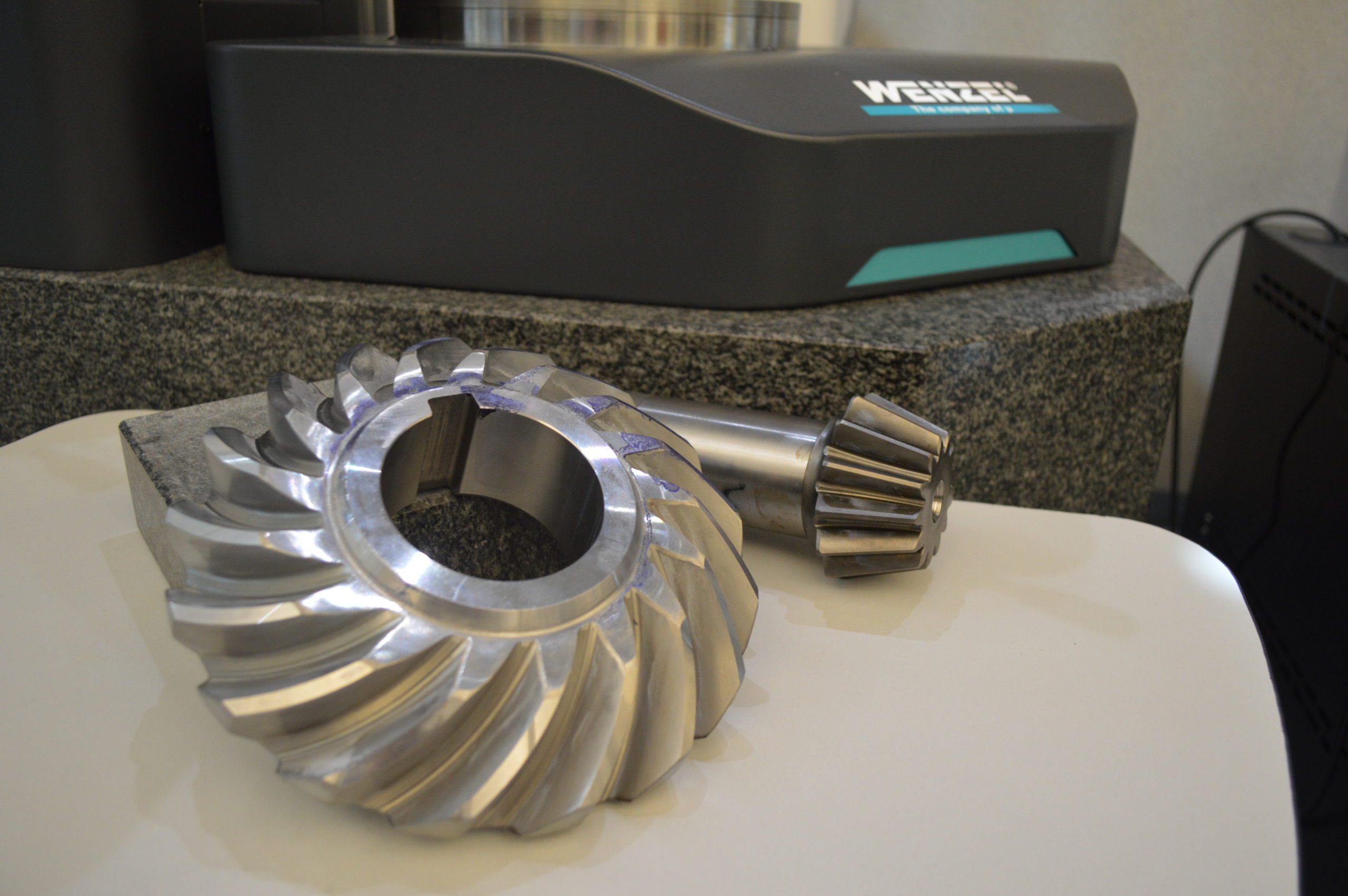

Bevel gears – Spiral or straight, VDA file or not, we can send the corrections right back to your machine tool so you come back with the right bevel gear every time.

Bevel gears – Spiral or straight, VDA file or not, we can send the corrections right back to your machine tool so you come back with the right bevel gear every time.

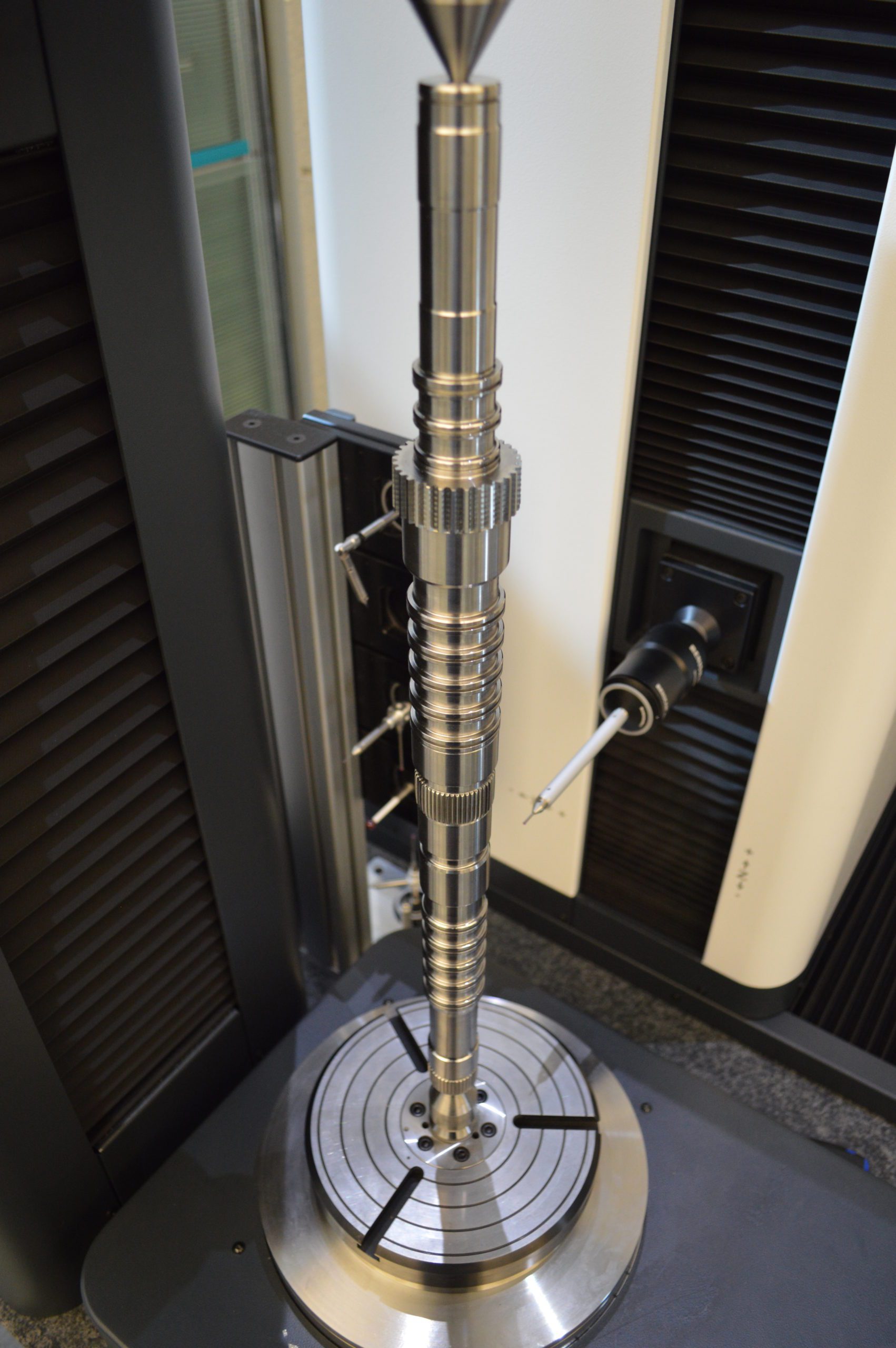

Shafts – What GD&T would you like from your shafted parts? Doesn’t matter, TShaft will tackle it. This includes cams as well. Distances, roundnesses, and true position of your bore pattern are just a few of the measurement tasks available with the click of a button.

Shafts – What GD&T would you like from your shafted parts? Doesn’t matter, TShaft will tackle it. This includes cams as well. Distances, roundnesses, and true position of your bore pattern are just a few of the measurement tasks available with the click of a button.

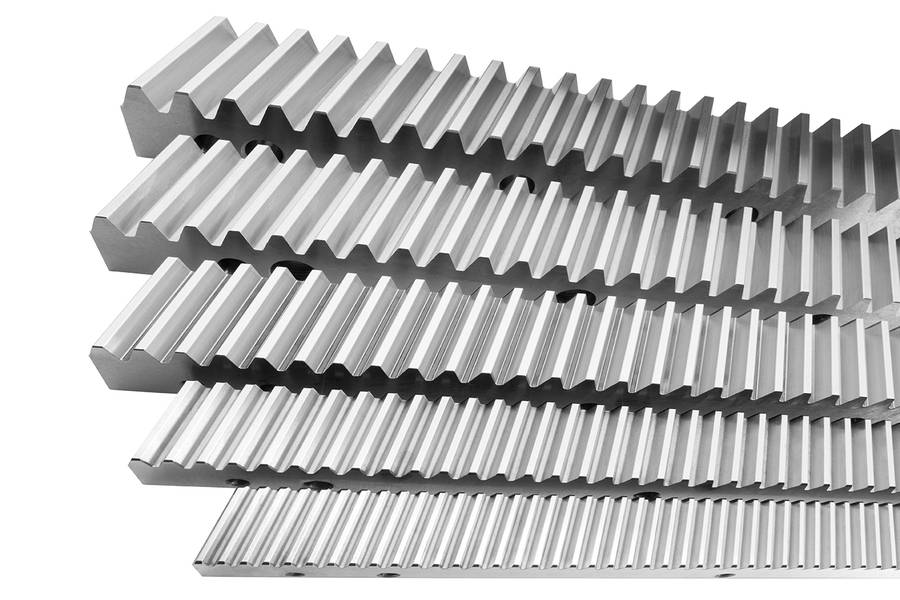

Splines – With TSpline, you’ll be able to measure square splines (like in the picture on the right) and straight-sided splines (think shark teeth) with the same parameters and ease as gears in TGear.

Splines – With TSpline, you’ll be able to measure square splines (like in the picture on the right) and straight-sided splines (think shark teeth) with the same parameters and ease as gears in TGear.

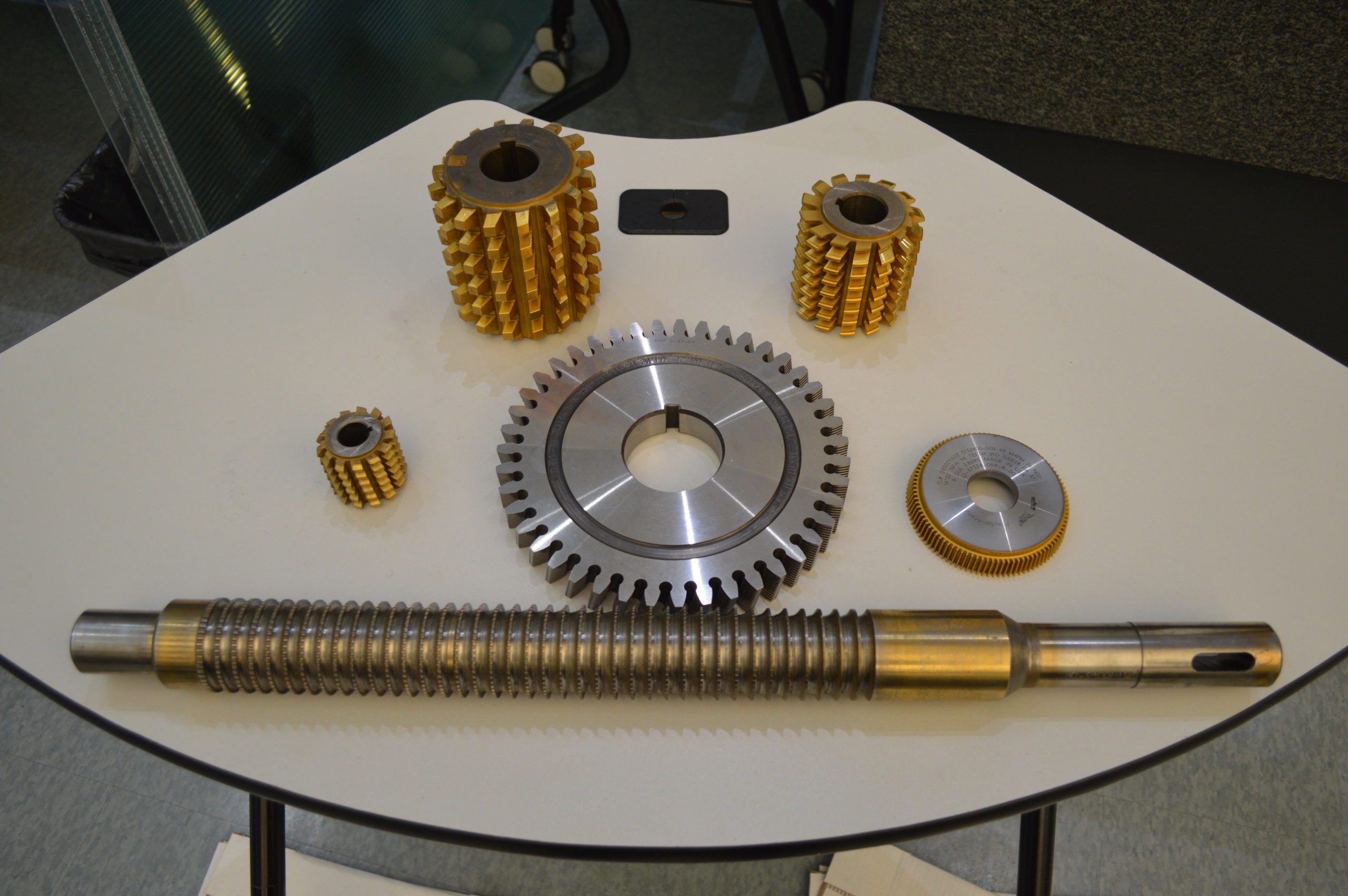

Worm gears and worm wheels – These unique gears are not a problem for our WGTs, even if theyre enveloping. Get the topography of your worm wheel right away for 1, 2, 4, or all teeth.

Worm gears and worm wheels – These unique gears are not a problem for our WGTs, even if theyre enveloping. Get the topography of your worm wheel right away for 1, 2, 4, or all teeth.

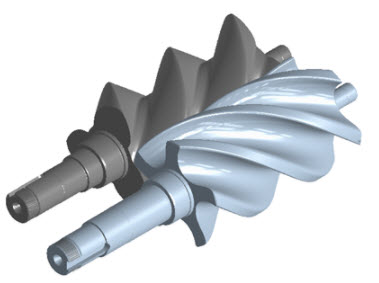

Rotors – These fun parts can be inspected with big styli whether they be male, female or helical (straight). Just load the VDA file and you’re ready to go in TRotor.

Racks – You’ve heard of rack and pinion steering in your car. Well, that gear rack might’ve been inspected with a Wenzel. Big, small, helical, they aren’t a match for the WGT.

Racks – You’ve heard of rack and pinion steering in your car. Well, that gear rack might’ve been inspected with a Wenzel. Big, small, helical, they aren’t a match for the WGT.

Shapers, shavers, hobs, and broaches – Gears can’t be made right if the tools that make them aren’t right. This is what our suite of cutting tool inspection modules are ready to verify – that each flank, lead, spacing, and rake angle was sharpened correctly to a AAA standard. This will allow you to make the best gears every time.

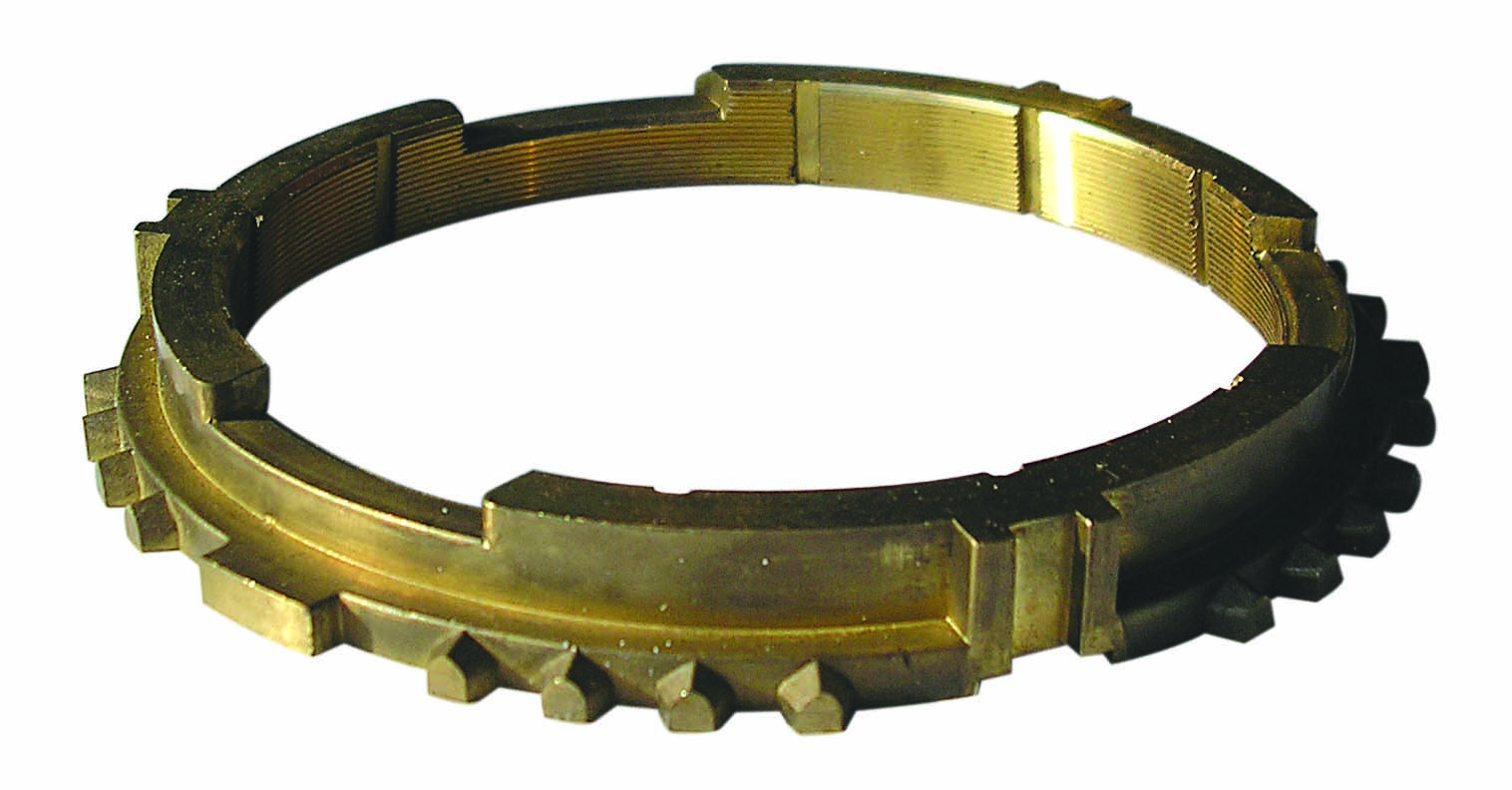

Synchronizer rings – These guys help us change gears in our cars so of course they need to be made, and thus, inspected, right. The WGT can measure them up, down, left, right, and all around these special teeth with the help of the TSync software module.

Synchronizer rings – These guys help us change gears in our cars so of course they need to be made, and thus, inspected, right. The WGT can measure them up, down, left, right, and all around these special teeth with the help of the TSync software module.

Reverse engineering – If you aren’t fully sure of your gear’s parameters, our TReverse software module allows you to take your helical or spur gear and reverse engineer its module, pitch diameter, and pressure angle and throw the data right into TGear to fully check it!

Reverse engineering – If you aren’t fully sure of your gear’s parameters, our TReverse software module allows you to take your helical or spur gear and reverse engineer its module, pitch diameter, and pressure angle and throw the data right into TGear to fully check it!

Now you know that you’re able to inspect all of these different kinds of parts all to the latest standards in the gear industry as well. It’s not just a GMM, it’s an all-around wholesome solution for any gear shop nationwide. Do you prefer a CMM solution instead? No problem! Everything above applies to our LH Gears as well. You just name the size and we’ll build you that CMM with an integrated rotary table and our trusted Renishaw sensors.

Should you have any questions about this powerhouse inspection machine, or any other gear applications, don’t hesitate to contact me here and to follow me on Twitter @GearMarks! If not, as always, you can check out our website at www.wenzelamerica.com. Happy gearing!