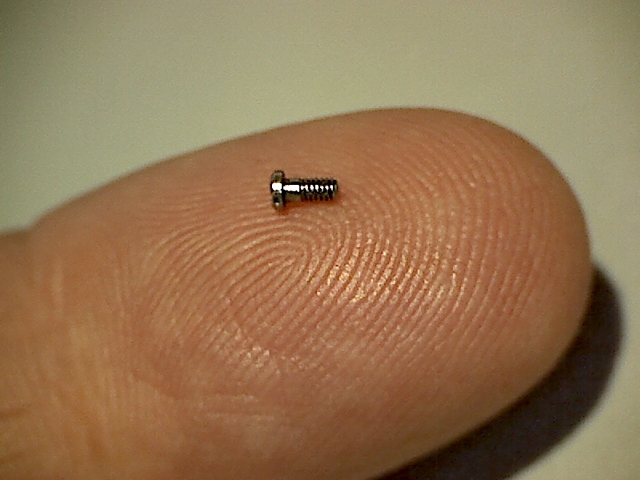

Anyone who wears eyeglasses knows two things. Firstly, it’s highly irritating not least debilitating when your glasses break for whatever reason. Secondly, the little screws that hold glasses together are about the smallest engineered parts you ever have to deal with in normal life, so much so, you can hardy even see them (and in fact you can’t see them when your glasses are broken!). But what does this have to do with 3D Scanning you ask? Read on!

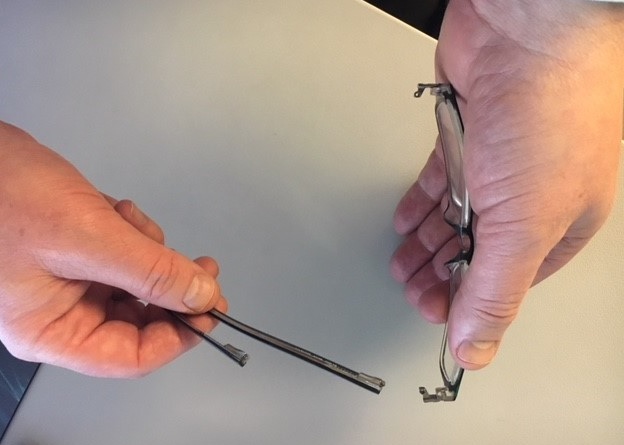

I recently had exactly that problem after my prescription reading glasses became very loose. I called in to the Eye Doctor’s and the technician told me she could tighten them up but in no uncertain terms made clear that if she broke them in the process it was on me. I told her I’d take the risk. That turned out not to be my best decision because though the glasses seemed tighter and much improved what I put them on, they fell apart shortly after.

Trying to see what the problem was proved impossible not only because I didn’t have my glasses but also because the component parts are so incredibly small I got to thinking this has to be a problem for any one in engineering development or quality dealing with parts that are this small so I decided treat this eye glass problem as if it was a problem presented to me by a customer in my capacity as CT Services Manager at Wenzel America. I wanted to see how we could solve this problem with 3D Scanning.

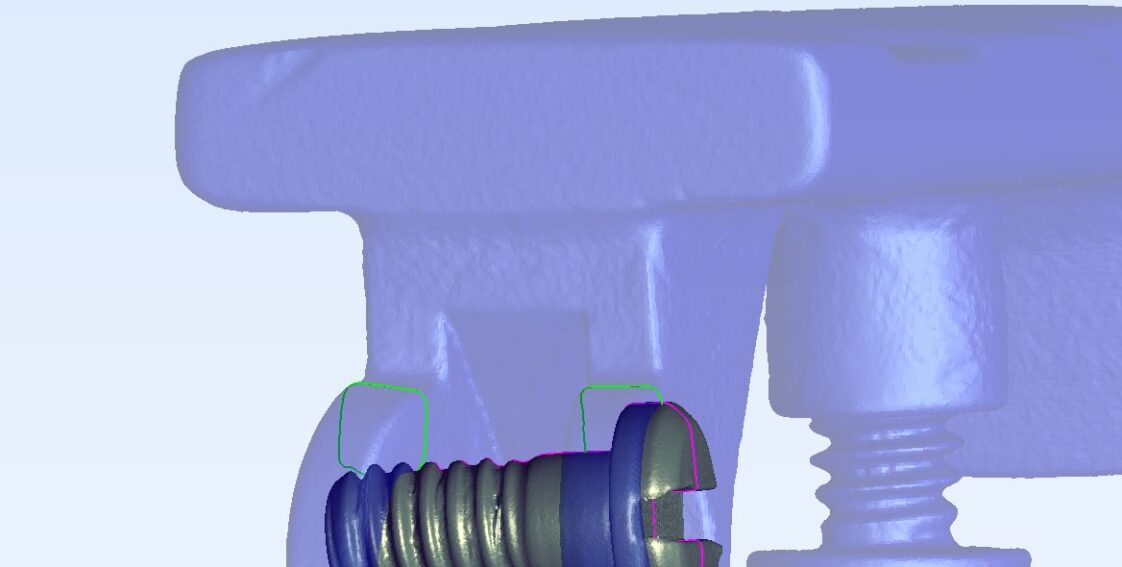

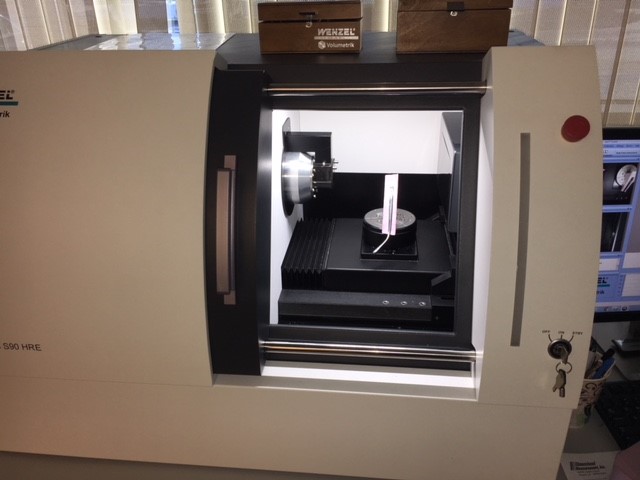

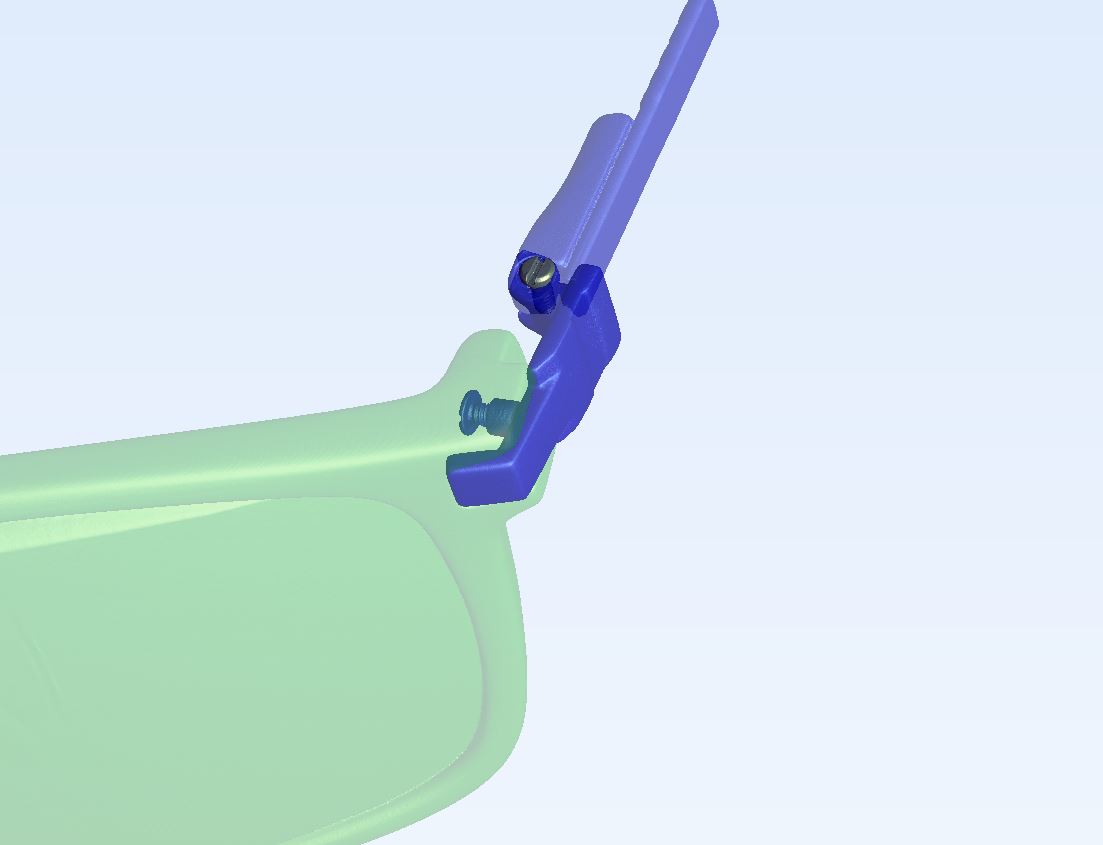

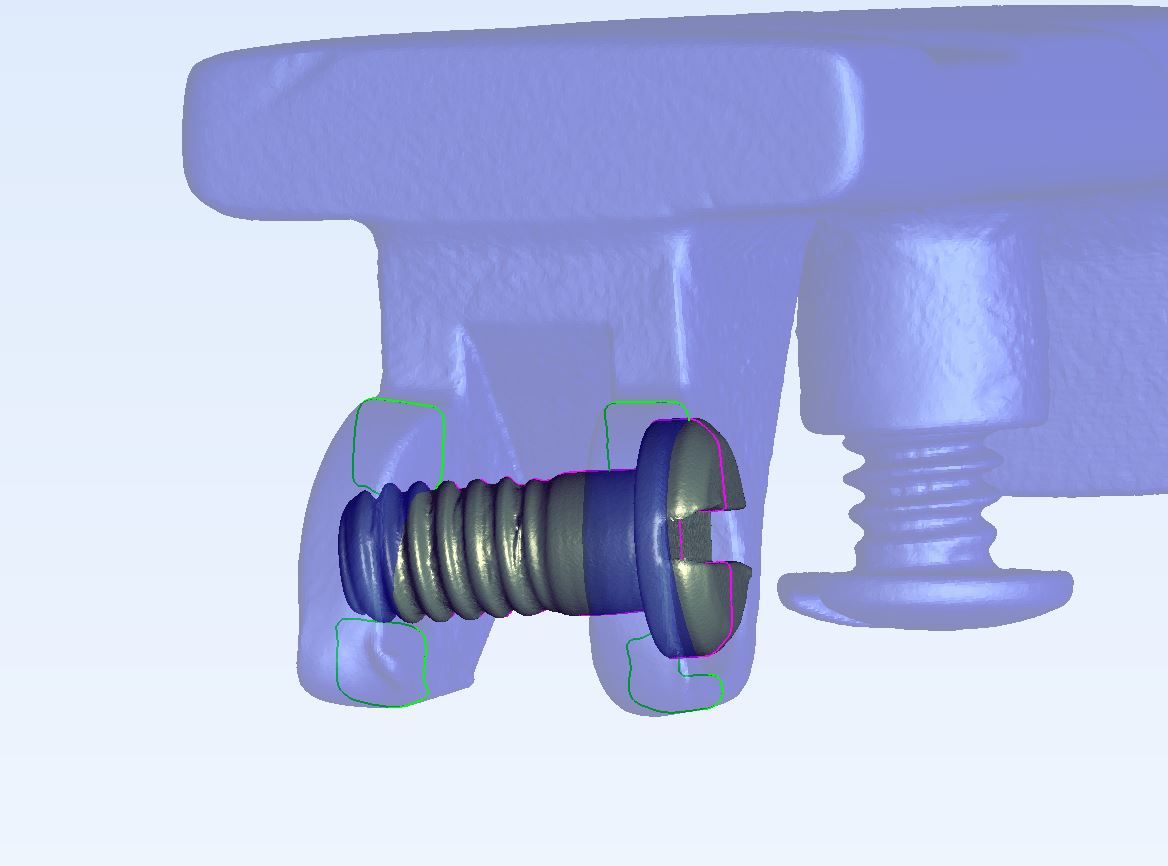

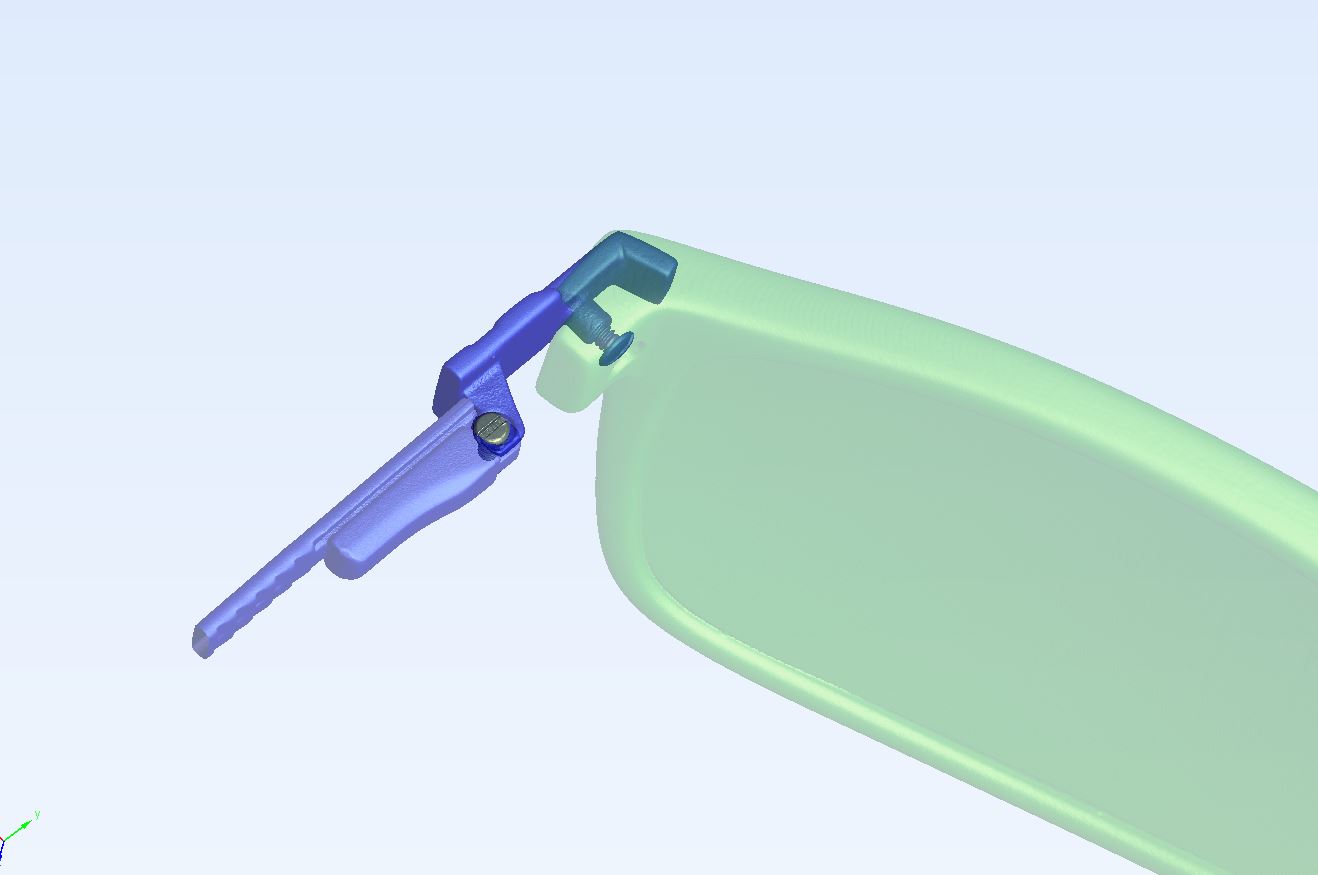

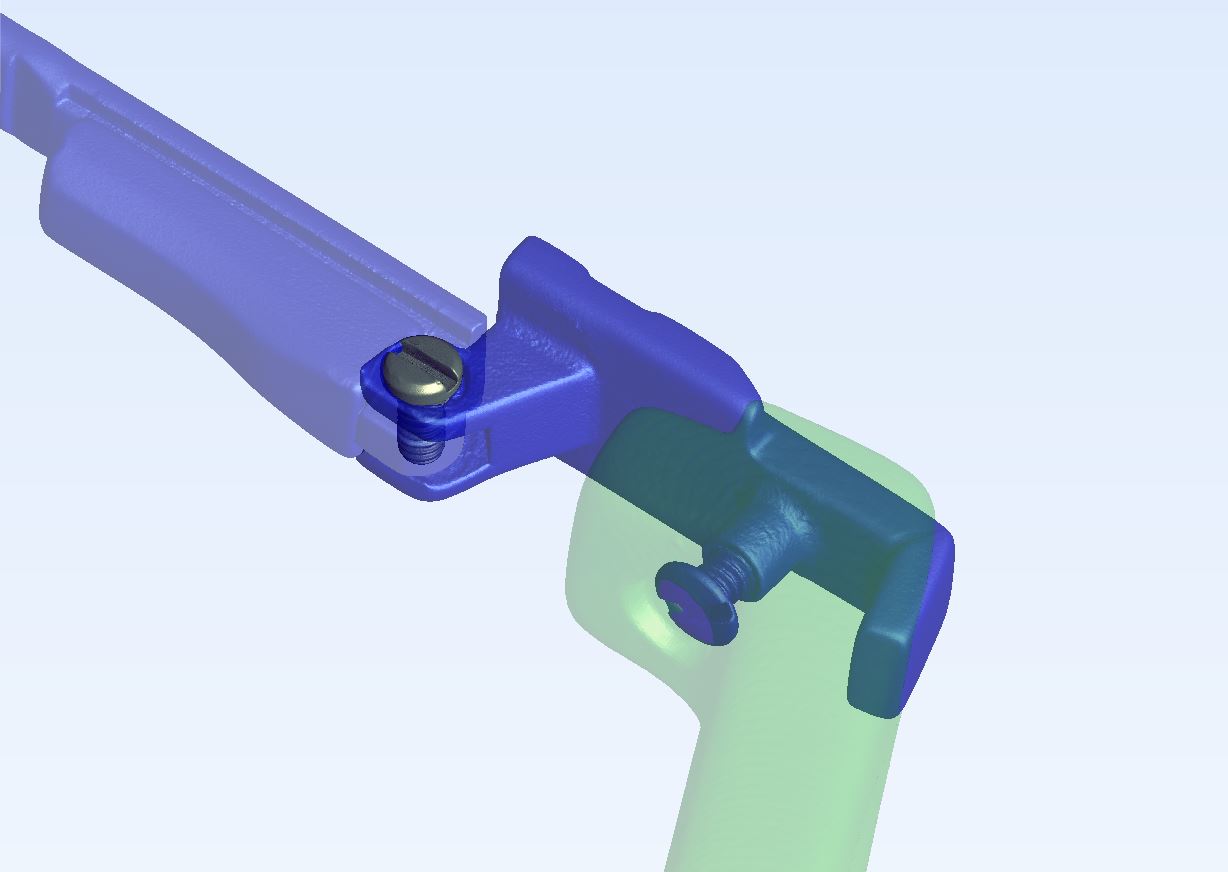

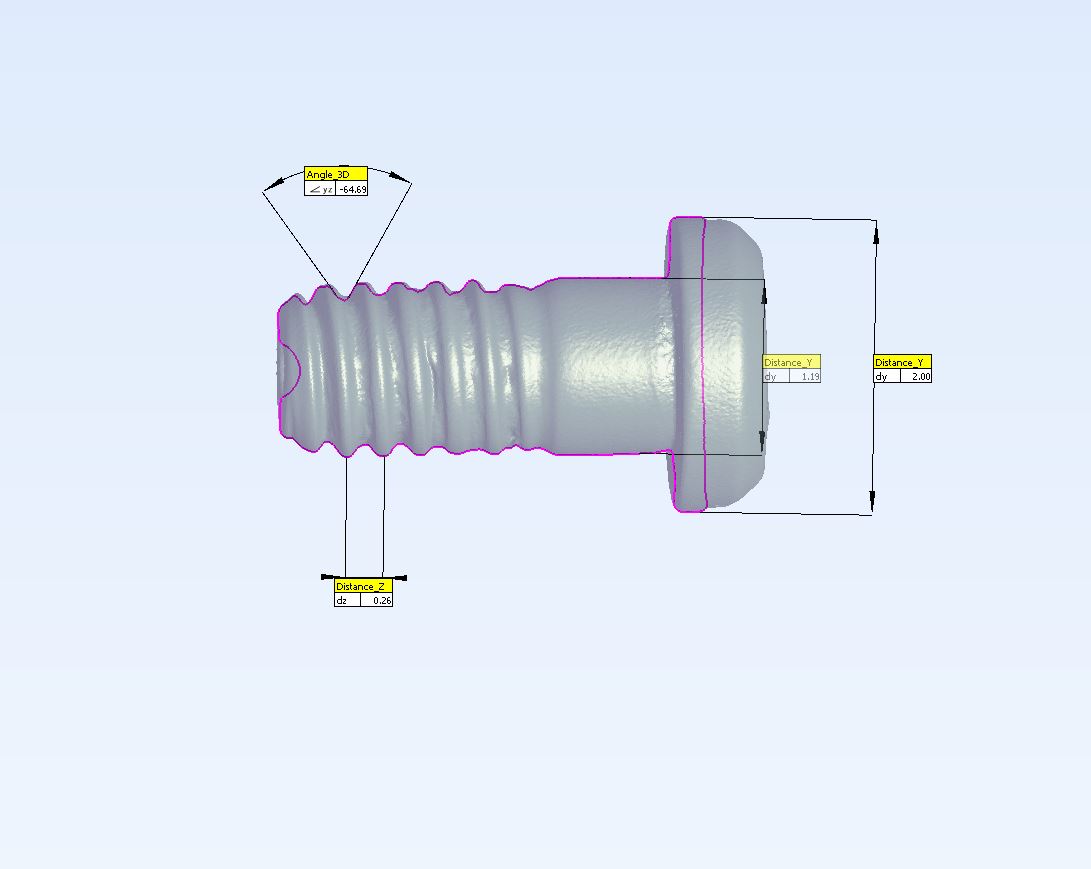

I scanned the parts in our Wenzel Volumetrik exaCT S machine that if needed can scan really tiny parts at a resolution of 4 microns. You can see from the pictures that the definition and clarity of the part scans is superb and it is not difficult at all to see what the problem is and accurately measure the parts. From what I could see the technician had over-tightened the screw into a thread that was bent of axis by 20 degrees resulting in that thread being stripped. This was very useful information that enabled me to fix the glasses.

Without a CT scanner; How do you analyze and measure such small parts and assemblies in 3D? Not something I need to worry about (I know I’m spoiled) and you don’t need to either – Contact me or visit us here.