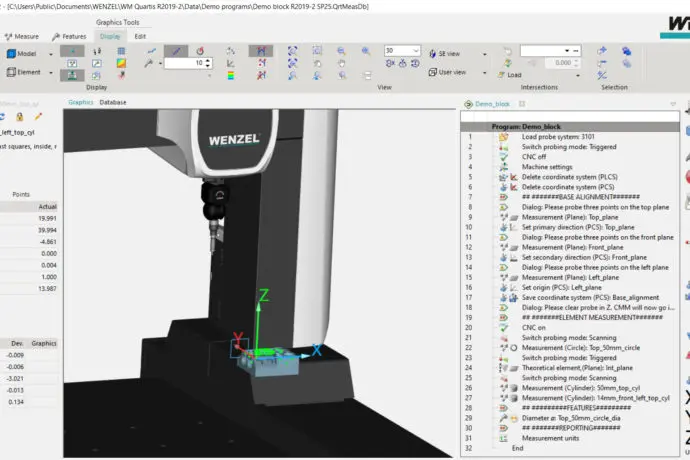

WM | Quartis

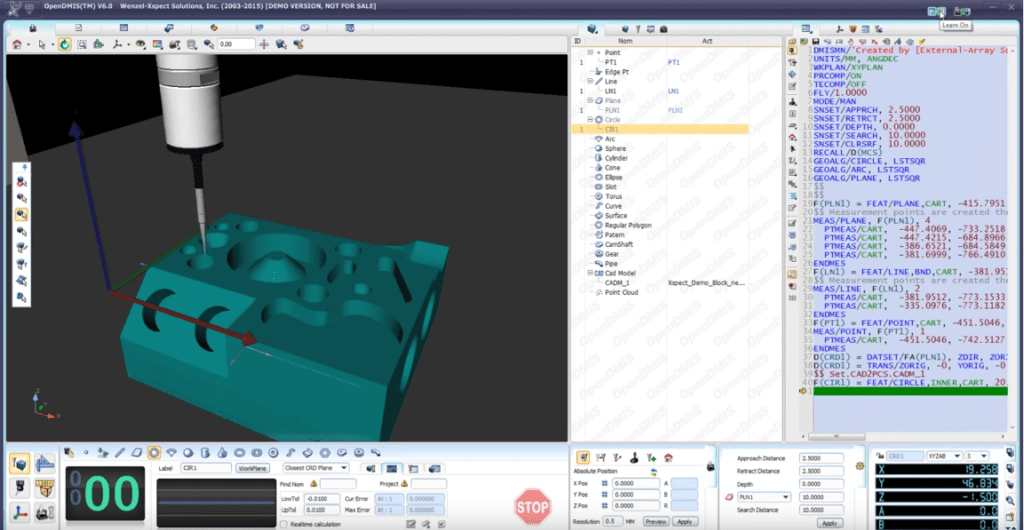

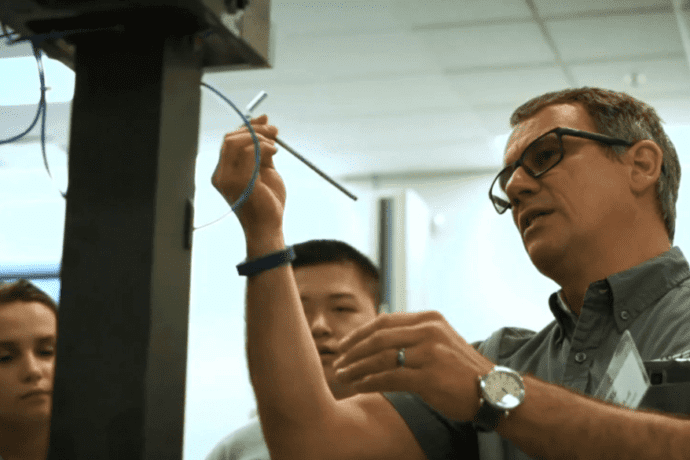

We’re dedicated to giving you the training you need to be successful. To commit to this, we offer both seminars and individual training courses. The seminars teach the basics of successful work and measurement with WENZEL software WM | Quartis, WM | PointMaster, WM | DesCAD and all of our other software solutions.

These individual training sessions are held specifically for your company. Our experts are able to coordinate the training you require. The content of the training is tailored to your specific needs and work pieces. All of our available training can take place online with your WENZEL expert or at your site. If you are interested in getting training on Quartis, online, or at your facility, be sure to reach out to us today. We look forward to assisting you with all of your training needs.