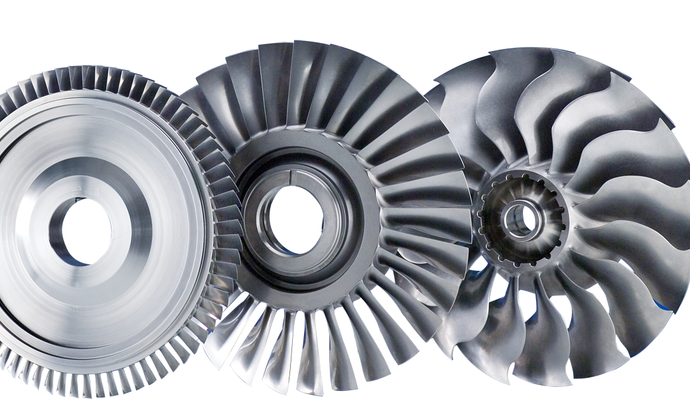

Turbine Blade Inspection

Turbine blades must produce enough power while withstanding high temperatures. To ensure quality and precision in design, we provide thorough turbine blade inspections. We use our state-of-the-art software and precision hardware to provide the most advanced aerospace CMM (coordinate-measuring machine) to check for accuracy in castings, shape and edge geometries, and more.