At times, a good team of metrologists must sharpen the axe to cut down some of those precious microns. Strengthening our understanding of the basic concepts of metrology will only allow us to expand our thinking and, thus, our knowledge base.

A team of employees in an organization should have no ambiguity when discussing even the most trivial of topics. This ensures efficiency, communication, and, what we’re all here for, quality. Luckily, an organization has been formed that helps metrologists stay on their toes on the basics of metrology while demonstrating the latest developments in the field. That organization is AUKOM.

AUKOM was a result of a three-year research project (1998-2001) of the Quality Research Association (FQS in Germany), financed by the German Ministry of Labor and Economy, in cooperation with the most important manufacturers, some of the more prominent users of coordinate measuring machines, and from research at the QFM – University of Erlangen-Nürnberg.

Its aim is to provide an up-to-date, comparable, controllable, comprehensive, and certifiable training regarding industrial production metrology, particularly in the area of coordinate metrology. This will result in three crucial aspects that should be inherent to anyone who cares about the quality of their products as well as their customers: to reduce costs, to minimize waste, and to make effective decisions.

The members of the organization have certified trainers which are responsible for the delivery of said training and also help promote the organization while ensuring that the standard and compatibility of the courses stays current. Overall, the courses help spread “good measurement practice” among production engineers, managers, design engineers, and, of course, metrologists.

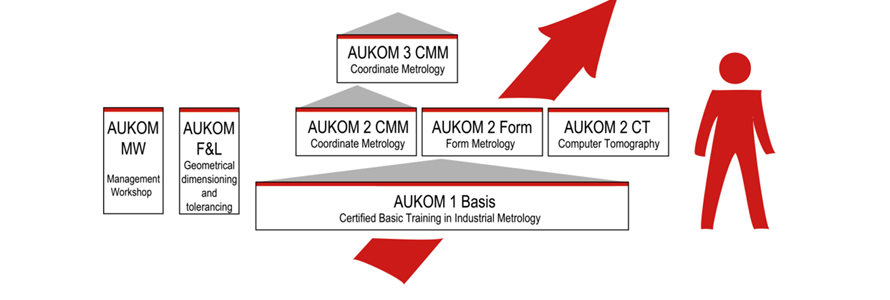

There are currently seven different possible courses available from AUKOM, although certain courses would only be needed depending on the student’s need and job. They provide a machine-free, manufacturer-neutral training that cover simple mathematics and physics concepts that relate to different CMM types and also metrology practices followed by worldwide standards.

The classes are carried out in a classroom environment, either on-site or at the partner company’s facility, for up to 12 students. Classes are in presentation format and students also receive their own training manual. Instructors also enhance the lectures with hand tools and CMM and software demonstrations, if possible. Another great aspect of the courses is the open discussion that is encouraged between the students which is natural given the different backgrounds of the students that attend.

AUKOM Level 1 is the most common starting point and is aimed at production metrologists, although those with a close relationship with metrology-related tasks or those who wish to get a basic introduction into the basics of metrology should start with this course.

This course covers basic dimensonal tolerancing, unit conversions, geometric elements, programming basics, machine and sensor technology, evaluation of measurements, uncertainty effects, and the importance of documentation and quality management.

AUKOM Level 2 is a continuation of Level 1 and has been split into three different categories depending on what type of tasks are carried out. The students can choose between a CMM, Form, or Computer Tomography tailored class.

Still, it delves more into form and positional tolerances, the measuring strategies of tacile, image processing, and distance sensors, freeform surfaces, evaluation methods, reduction of errors on the measurement results, documentation of results, and equipment monitoring.

AUKOM Level 3 is an advanced course that should be taken by those who have an extensive background in metrology. It challenges the students to think about digital filtering and evaluation methods, monitoring of CMMs to the ISO standard, measurement uncertainty and measurement, quality management, and process monitoring.

AUKOM Levels 1-3 courses consist of four days of instructional material followed by an examination on the fifth day which, if passed with a 67% or above, results in a certificate for the participant demonstrating their ability in the concepts covered by that course.

AUKOM 2 and 3 have the preceding level course as a prerequisite although the course content may be skipped and the examination alone can be taken. However, this is not recommended so as to not miss any thorough content that would be provided with the actual course.

There is also an AUKOM GD&T course which consists of three days of material with no examination and covers the GD&T symbols along with how the evaluations work with a heavier influence in the ISO standard. Differences between the ISO and ASME standards is also covered.

Finally, an AUKOM Management Workshop is also offered, which also consists of three days of material with no examination, for Quality Managers, inspection planners, vendor managers, and others. This course helps those in supervisory roles manage and monitor their production process through measurement control analysis while also explaining some of the more basic concepts like measurement strategies and the golden rule of metrology.

In summary, AUKOM is here to help you establish measurement results that can be compared worldwide. The biggest names in the industry have realized the importance of establishing and maintaining such standardized methodologies.

The Wenzel Group in Germany is proud to be a certified AUKOM partner and holds classes regularly! Keep an eye out for AUKOM courses in the US from Wenzel America.

For more information, please visit AUKOM’s website here or if you have any other AUKOM related questions, contact us here to see how you can get certified with AUKOM!

Mariano Marks

Sources:

http://www.aukom.info/en.html