We take “Child Proof” medicine bottles for granted and rarely have any problems with them. What a great idea, packages that take just a little bit more strength than a child can muster applied in a way you need to be able to read to understand.

We take “Child Proof” medicine bottles for granted and rarely have any problems with them. What a great idea, packages that take just a little bit more strength than a child can muster applied in a way you need to be able to read to understand.

I am like most people and have need to open one of these bottles every day. I don’t think I’ve ever experienced one fail before but recently I had one that from one opening attempt to another completely failed. This particular one required one to press the lid down onto the top of the container and turn slightly to disengage the teeth locking it on. It failed suddenly and completely in that the lid was completely locked solid; It wouldn’t turn and there was absolutely no movement up or down.

It’s in my nature to be curious as to what could go wrong with such a device, relatively new and not having been subject to abuse. How could it fail so suddenly and completely? You might think I’m being over dramatic, but as a result of my work at Wenzel America I am conditioned to take the failure of any device seriously. We at Wenzel America are continually being challenged by our customers, many of whom come to us to help them solve quality issues with safety critical devices ranging from ignition switches, seat-belts to various medical devices that simply cannot be allowed to fail in such a catastrophic way as this pill container had done. I was therefore more than a little curious as to what had gone wrong with it and keen to find out.

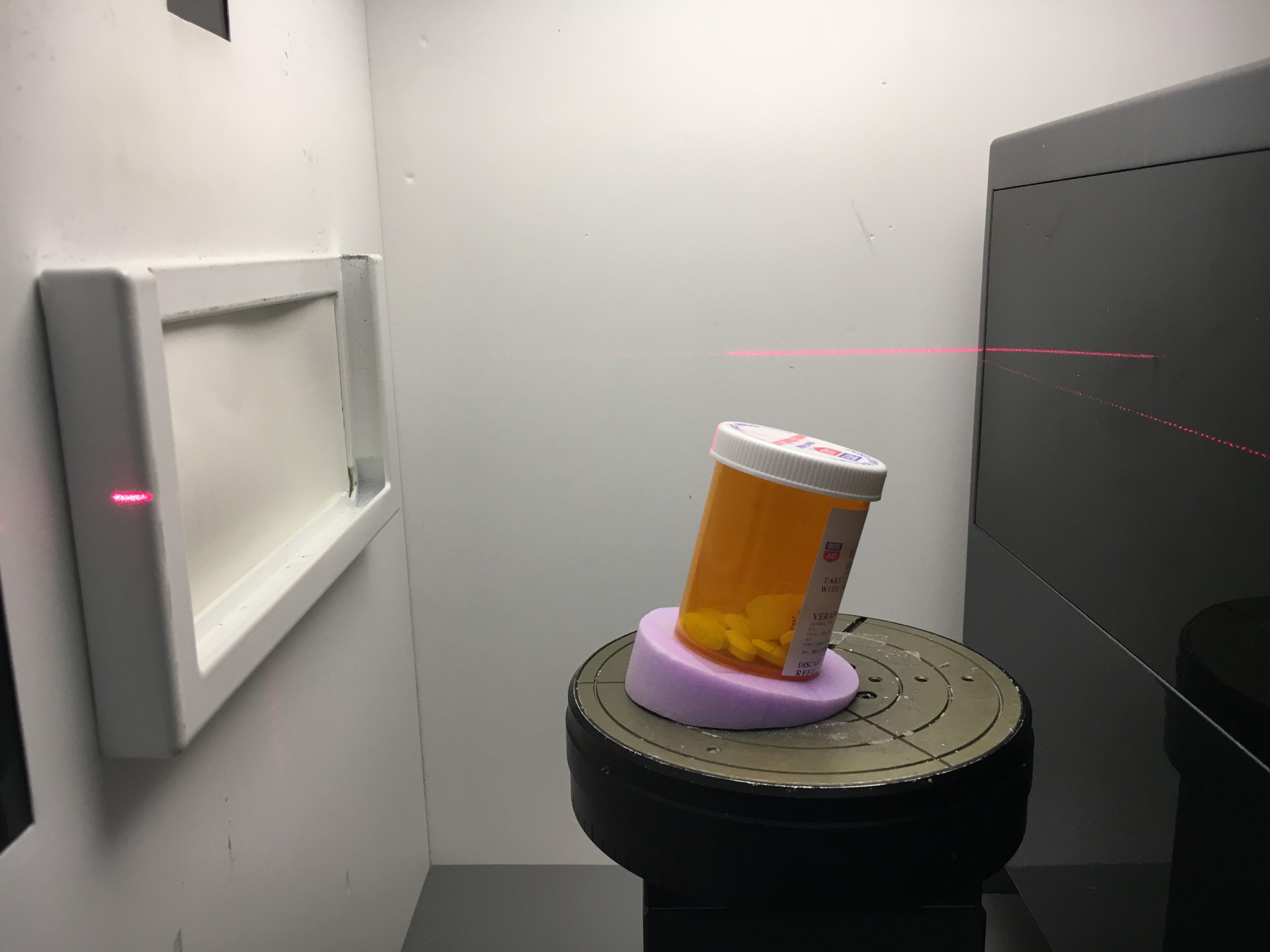

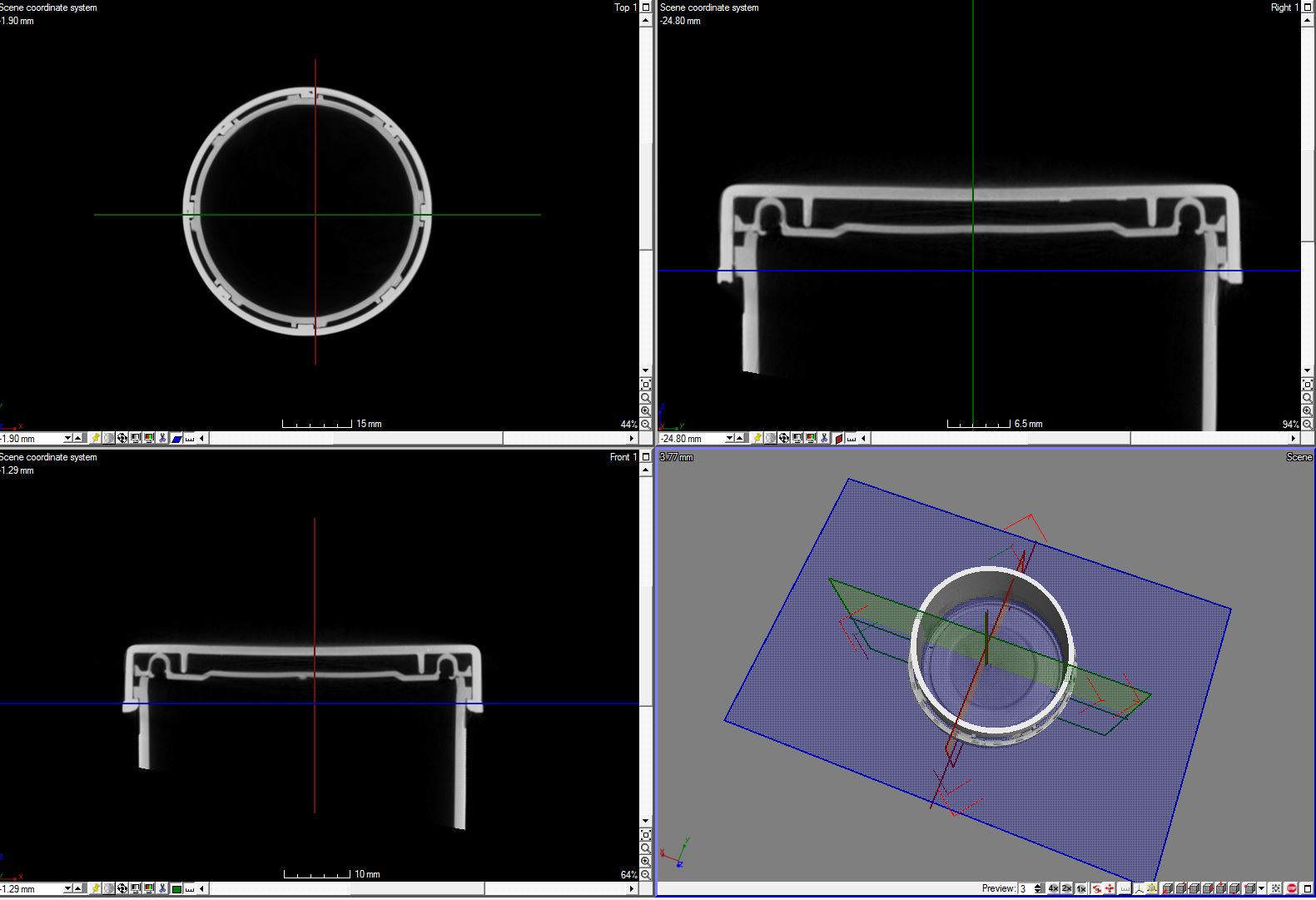

Fortunately, in my capacity as Manager of CT services at Wenzel America, I have at my disposal the finest range of tools available to anyone anywhere for solving this type of problem. Also, fortunately I was just about on the end of my prescription and was able to order and pick up a new supply of pills in a brand new (and fully functioning) container identical to the failed one. I took both of the containers and scanned each of them in the exaCT M CT scanner in our Lab.

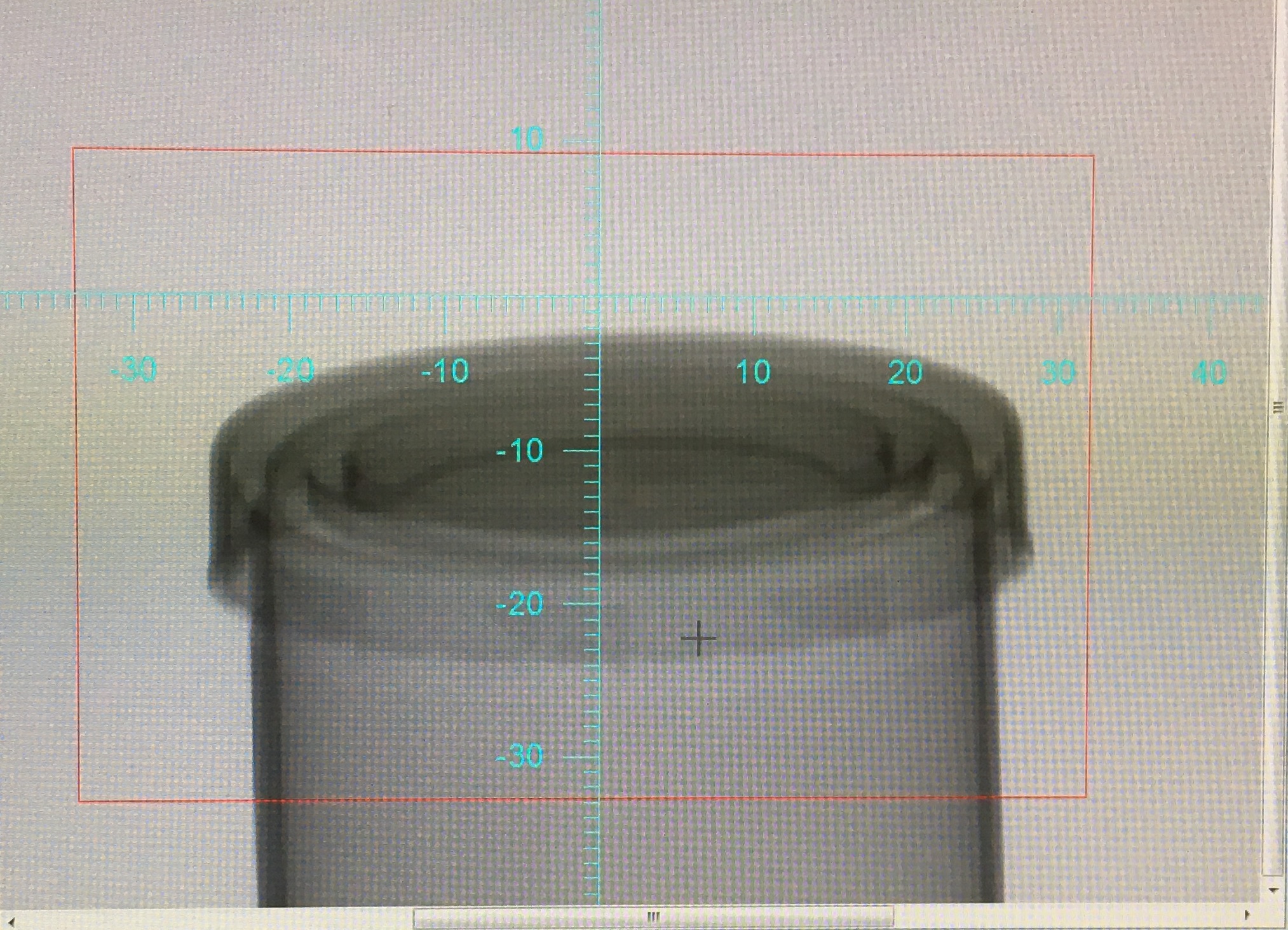

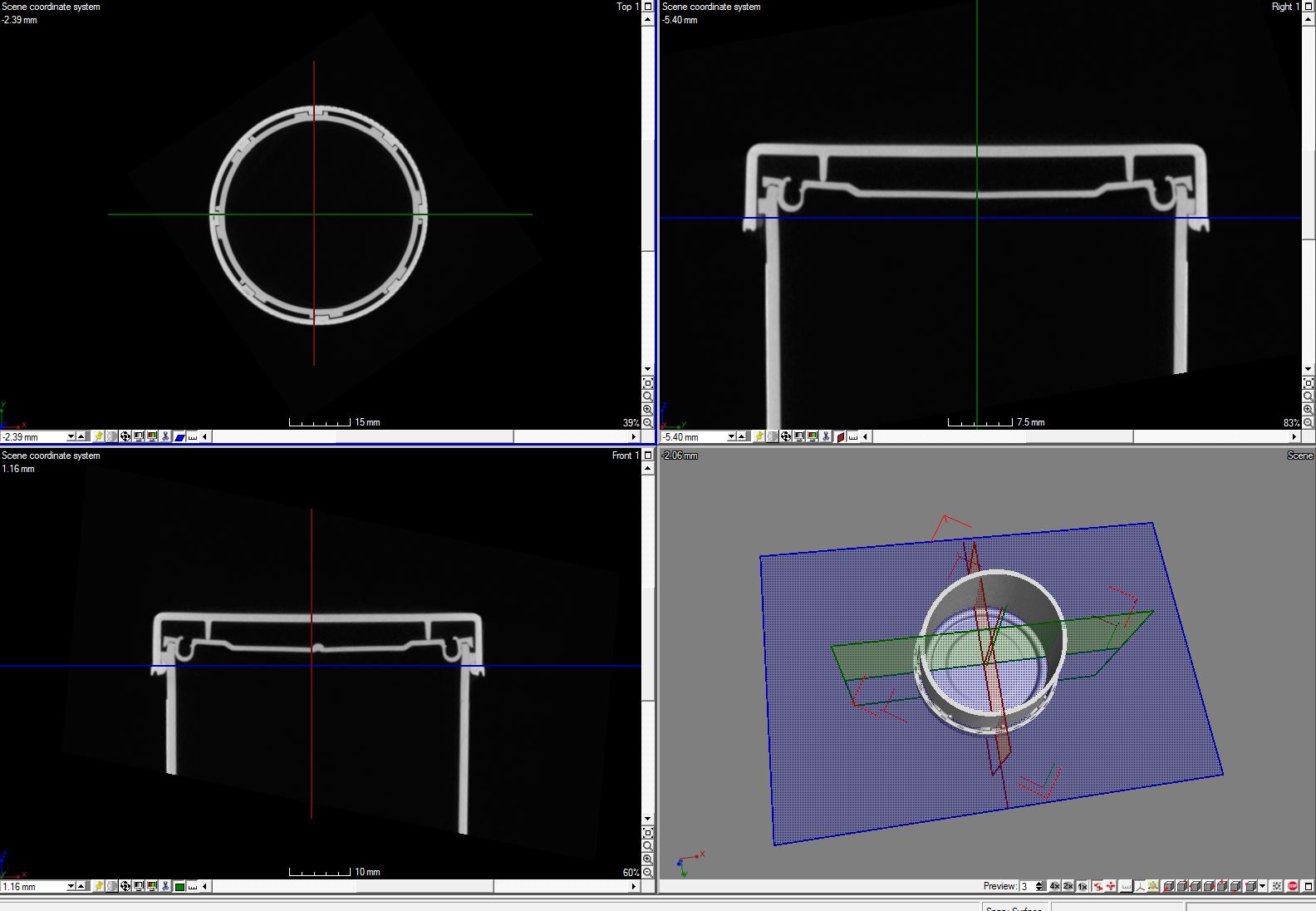

The way that the CT system works is that it takes maybe 600 X-Ray shots of the part then uses sophisticated mathematical algorithms to reconstruct all those 2D shots into a 3D “volume” through which slices can be cut to see what was is going on inside. My first look at the scans was to compare how they looked from above in a slice horizontally through the locking teeth. They looked exactly the same.

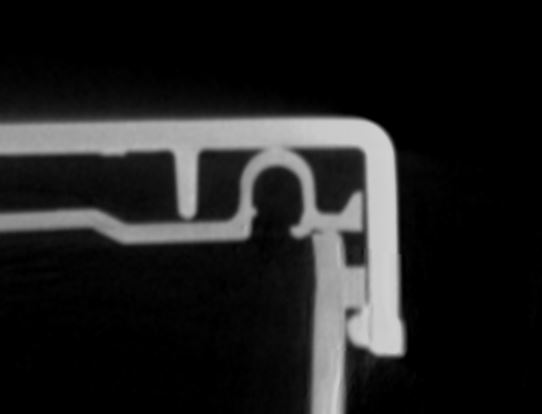

My second look was at a vertical slice though the middle and whilst on first glance they looked the same, it suddenly struck me that the toroidal feature under the lid that is that serves as the spring was completely flipped upside down on the failed device. This must have been caused by the inner lid falling out and being replaced upside down (by me I have to suppose though I can’t remember doing it) as from the detailed profile, it is clear it could not have flipped on its own. The question for the manufacturer would be; how did it fall out?

With no possibility of fixing the mechanism the next thing to do was take a knife to the bottom of the failed container to retrieve the remaining pills!

As it is clear from the pictures of the failed mechanism, CT is the best possible way of analyzing a failed mechanism without destroying the evidence of what has gone wrong. If you experience similar frustrations with one of your products that has mysteriously gone wrong; Contact Us.