Part To Be Tested: Car Sun Visor Hook

The test was done on a plastic injection molded hook used to hold car sun visors in place. Similar to many plastic automobile parts it’s small, fragile, and must function correctly for years.

Problem: Fully Analyze a Plastic Part Without Destroying It

Plastic must be formed precisely for components to function as designed. The injection molding process used to manufacture plastic parts is susceptible to causing warpage and voids. The part has to be fully accessible on all three dimensions to analyze these defects thoroughly.

To measure the part and detect all discrepancies requires first comparing it to a CAD model and then do a 3D Scan for porosity analysis. Traditional metrology and measuring methods can easily destroy the part and ordinary 3Dscans don’t return all necessary data points.

Solution: NDT 3D Scanning with Computed Tomography

Accomplishing a complete and precise analysis of both form and porosity without destroying the part can be tricky. Industrial computed tomography enables the most complete and precise non-destructive testing (NDT) of both inner and outer structures. Our exaCT desktop CT 3D scanning machinescan be used to provide a holistic analysis and full data set in a small metrology lab setting. Both the exaCT® S and XS can the part can be utilized to capture and reconstruct all surface and interior data.

Results: Computed Tomography 3D Scans Give Full Data Capture

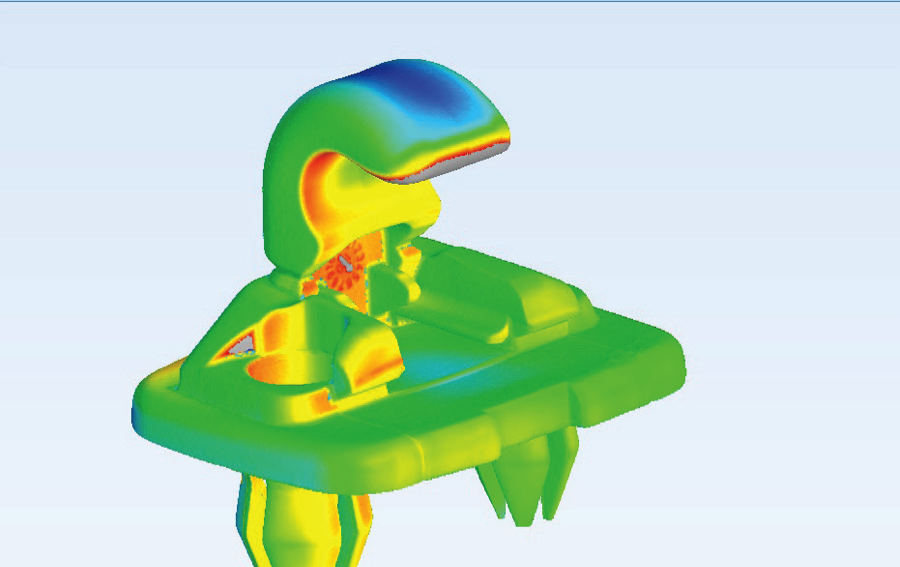

Point clouds captured with a computed tomography system are transferred to surface data in what is called STL-Format. With an actual-to-nominal-comparison

the 3D scanned surface data and original CAD model are analyzed for discrepancies. Any deviations of the surface data to the CAD model are shown with color variations.

Wenzel America exaCT Desktop CT Industrial Scanning Machine

Nominal to Actual Comparison 3D View with Wenzel America’s exaCT Desktop CT 3D Scanning System

Nominal to Actual Comparison Selectional View with Wenzel America’s exaCT Desktop CT 3D Scanning Machine

The 3D porosity analysis also shows all voids within the component in varying colors. The color-coded voids are assigned to different size categories, allowing for an easy estimation of sizes and void distribution.

Porosity Analysis with Wenzel America’s exaCT CT 3D Scanner

About Wenzel America

Wenzel America Ltd. is a wholly owned subsidiary of Wenzel Group of Germany. We sell and service Wenzel’s exaCT CT 3D Scanning machines. To see the full power of CT 3D Scanning Machines in action subscribe to our newsletter. We’ll do one free exaCT analysis CT 3D Scan just for signing up. We also perform professional CT 3D Scans and part inspection analysis as a service for medical device, automotive and other manufacturers. Contact the Wixom, Michigan Headquarters.

Sources:

A Wenzel America, Ltd. case study based on the article: Form and Porosity Analysis of a Plastic Injection Molding Component by Dr. M. Simon and Dipl.-Ing. (FH) S. Schadek WENZEL Volumetrik GmbH.