Preserving Motorcycling history with CT Scanning.

I recently made use of the latest CT Scanning technology to help me preserve some motorcycling history. What I did can be put to good use by anyone in industry looking to keep a record of a legacy product or keeping an old design alive; This not just a hobby activity, it is a mainstream concern in many industries such as in aviation and the military given the US Air Force is still using airplanes designed in the 1950s

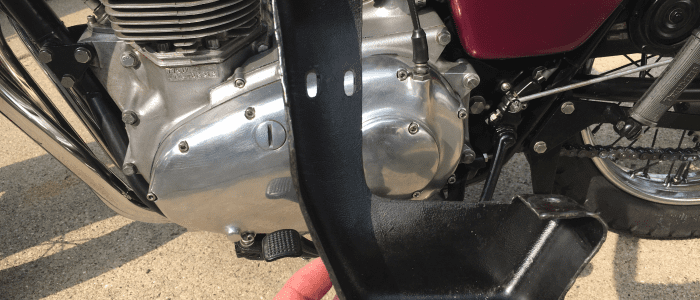

I restored a 1972 Triumph Trident over a period of 5 years. It’s possible to source almost every part for the bike from second hand dealers, remanufactured designs and new old stock parts except for one or two parts that were molded rather than machined and which have a non-uniform and not easily replicated shape.

One such part is the tool box which fits snugly behind the left-hand side panel and is a very tight fit. Despite its apparent simplicity it is in fact a very complex part. There is not a single flat surface, no part of it is at right angles to another and the thickness is constantly variable. I cannot believe the part is accurate to its original drawing (if it ever had one) but it works. Does this sound familiar?

As well as being a difficult part to tool for and reproduce making it uneconomic for anyone to have manufactured as a spare, it is also prone to wearing out early due to the back of it being exposed directly to the oil and dirt from the final drive chain and the weather. The net result is that after 40 years there are no second-hand ones in in circulation as they have all been destroyed.

Fortunately, I managed to find a brand-new tool box still in its original wrapper from the 70s and of course it went on the bike to complete the rebuild. Before It went on the bike however it took a trip to the Wenzel America offices where I used CT Scanning to get an exact STL of the geometry. That way, its complex shape is on record so at any time in the future that my original falls foul of the final drive chain I will be able to get a new one 3D printed in whatever the most suitable, durable material available is at the time.

CT Scanning captures every aspect of the part scanned, It’s geometry in every detail, visible and invisible including as its internal structure, glass fibers even the porosity in a molding. Once captured it’s there forever irrespective of whether the part itself wears out or gets damaged and available for making as many replicas as will ever be needed.

Being able to reproduce parts that you know are fit for purpose, possibly in a superior wearing material is of vital importance to anyone tasked with keeping an older design in service or taking a successful prototype into production and the use of a CT scanner guarantees that the exact geometry can be reproduced with nothing lost in translation through prints and CAD. I obviously have a big advantage over most motor cycle restorers in that I have ready access to this wonderful technology but its available to anyone as a contract service if anyone for anyone with a need. Give me a call at Wenzel America in Wixom and I’ll be happy to discuss your project. Check out our CT Scanning Services page here.