What is left to check with a CMM?

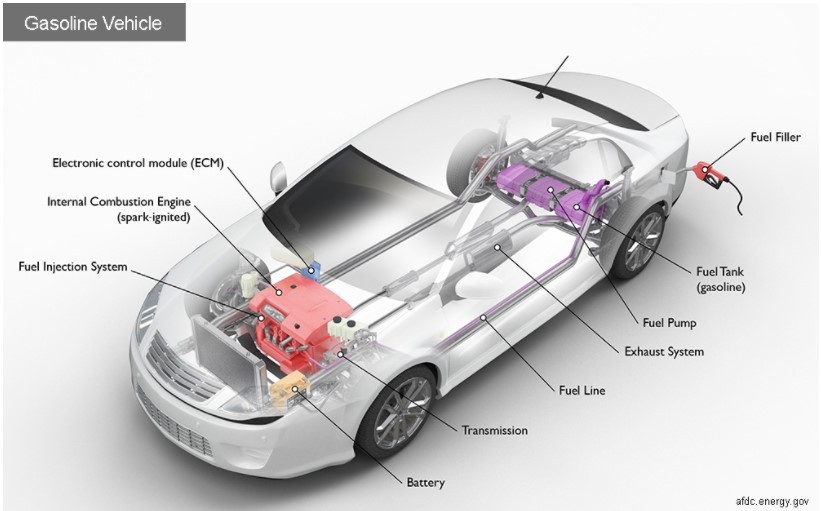

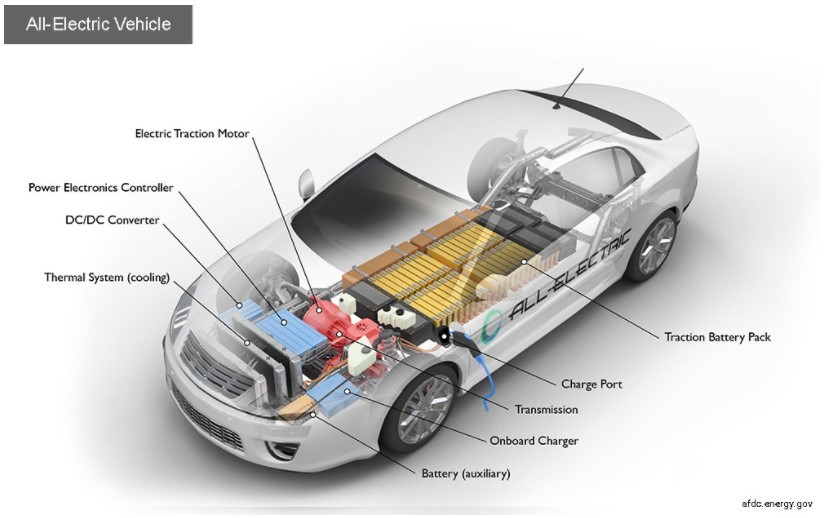

EV and ICE (Internal Combustion Engine) vehicles share some of the same components. On a macro level, they have tires, bodies, windshields, it’s when you start considering the drivetrain things change, radically. What’s left to check with a traditional CMM?

The engine of ICE vehicles is enormously complex when compared to the propulsion system of an EV. The engine itself has hundreds of holes that can be check to ensure that the engine is being manufactured to to stated tolerances.

Most engines have at least three major pieces a block, head and a crank, that when assembled make a the basic parts of an ICE.

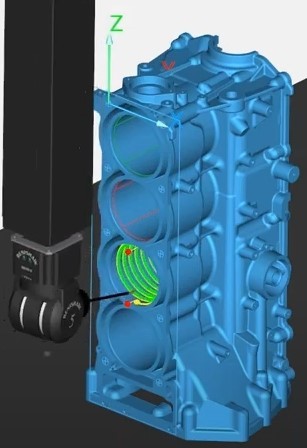

If the picture to the left, is an example of some of the measurements that are taken on one of these pieces. You can see the number of holes on the block that need to be checked.

And to be fair, every single hole is not checked on every single engine. Additionally every single hole is not critically tolerances, but the fact remains that there are a lot of features to check on the ICE. There is no “engine” to check on an EV. There are mainly motors. So, what needs to be checked on a motor?

Motors are the new engines?

Marposs has a great page detailing how they check motors.

“Motor testing is designed to check the integrity of an electric motor through the use of equipment that identifies potential issues within the motor.

The main objective of motor testing is to reveal latent problems and prevent unnecessary failure by evaluating static parameters like insulation, wire damage and electrical current leakage, as well as more dynamic parameters.

The insulating system of electrical machines is a critical reliability feature since an insulation failure may result in a system breakdown.

The standard electrical tests, required by regulations, are not sufficient to identify all types of failure, because many defects produce just partial discharges and these can only be identified using the partial discharge test method. “

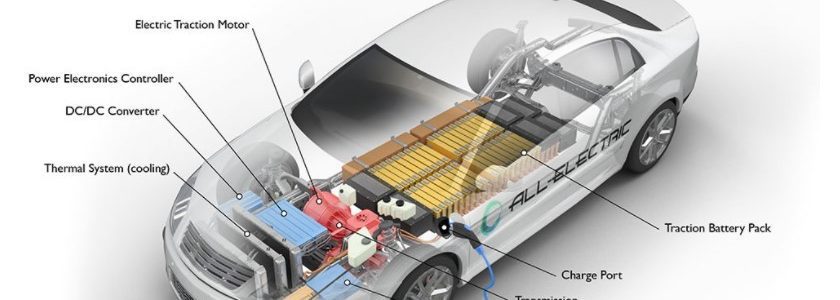

What about the battery?

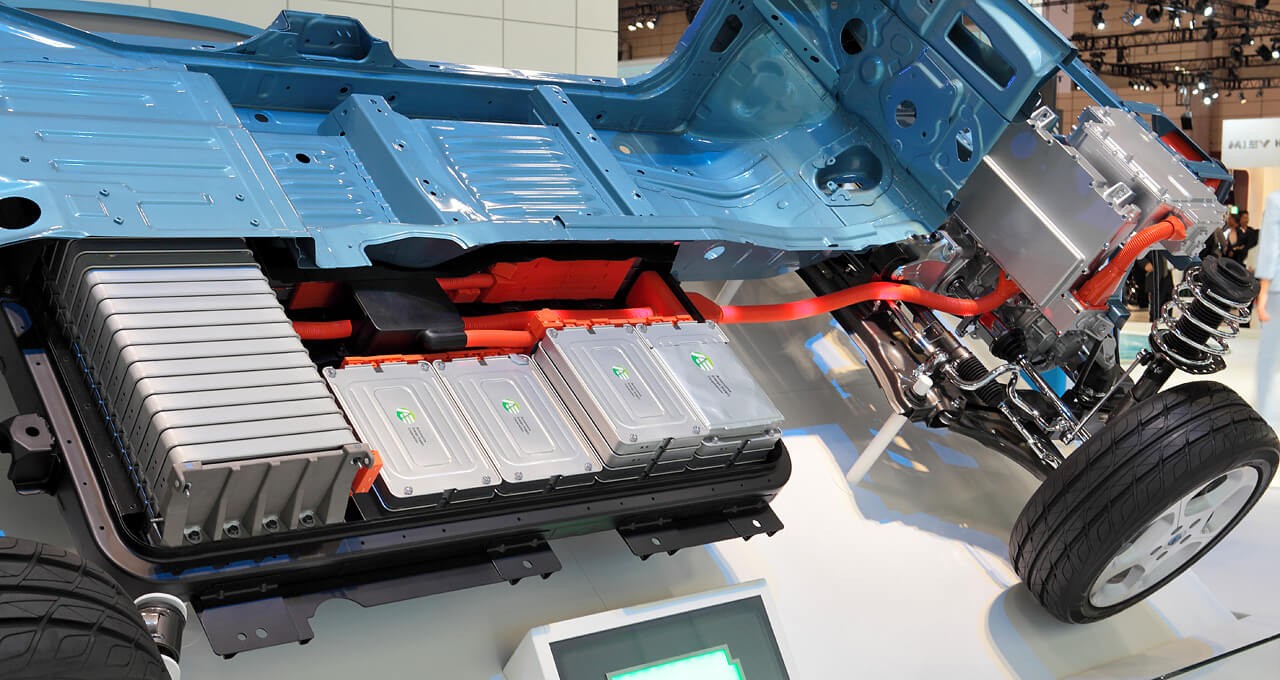

A fantastic blog post by By Carlicia Layosa on how battery packs are manufactured. She gives a clear overview of how the battery is assembled until it is fitted into the vehicle as shown in the picture. It covers some of the QC needed, but there are not a lot of reasons to do dimensional checks.

The thing that stands out to me is that a CMM is no where in any of this process. When compared to an ICE, a whole new paradigm is created in thinking about metrology for the EV drive train. I can imagine in this picture the tray that holds the batteries may have been checked. Also, the sheet metal would have been checked on either vehicle in any case.

Motors, motors, motors.

Eric Adams EricAdams321 wrote an in depth article on , “The Secrets of Electric Cars and Their Motors: It’s Not All About the Battery, Folks”.

From the article “While the electric motor has its own century of progress under its belt, there’s still much that can be done. Consider, for one thing, that most carmakers have brought motor manufacturing in-house.

If there weren’t room for innovation, they’d just order them out of a catalog from external suppliers. Lighter materials in motor construction, new alternative solutions for rare-earth magnets, and optimized overall performance characteristics for different vehicle demands are all very much in the crosshairs of automotive engineers. And that’s just the start, says Venkat Viswanathan, a mechanical engineering professor at Carnegie Mellon University who studies EV performance. ”

If you care to learn a little more on the “new” engines of EV’s, take a moment and please feel free to read the article. It is in depth and informative.

Everybody needs to lose a little weight.

Andrew Halonen is president of Mayflower Consulting, LLC, wrote a great article on “ELECTRIC VEHICLE MATERIAL SELECTION FOR CHASSIS AND SUSPENSION COMPONENTS”

This article goes over the other parts of the car in relation to the use by EVs. One topic I found interesting in this article was the need to reduce weight on the vehicle and the various areas manufacturers are selecting to reduce the weight.

He identifies chassis and suspension, braking systems, and materials choices as a few of the areas that they consider. This is another great read to give you a better understanding of the areas that are impacted vs. traditional ICE vehicles.

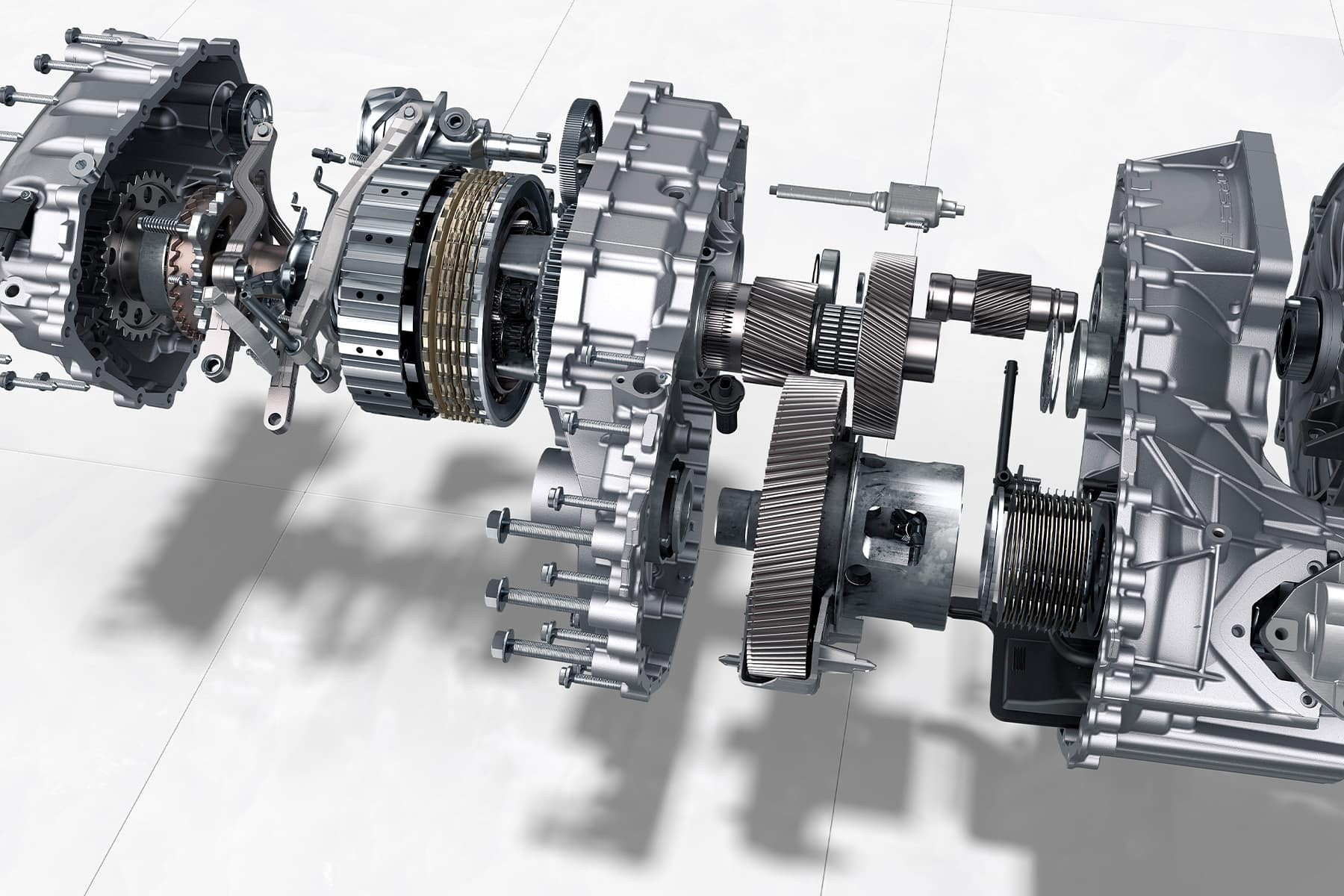

Grinding gears

The main area where traditional metrology will still be needed is on the gearbox side. This article, I recently reference is the final piece to this story. All vehicles need more advanced transmissions as ICE need to meet CAFE standards which spawns, 6,8 and even 10 speed transmissions. Here is an interesting article on “The Past, Present, and Future of Electric Vehicle Transmissions.” from Current Automotive.

In the area of car bodies, chassis and similar components, what could be considered traditional metrology, even something like body in white, will still remain. In the area of the powertrain the engine vs. motor will absolutely change how manufactures consider working on the metrology.

The importance of gears, and the ability to refine them and make better quality components will increase. One last point to consider about gears and EVs. Now that the roar of the engine is gone, the sound of the transmission and road noise is going to become more noticeable. Enjoy the Silence