Sometimes if you’re searching for Wenzel, you may run into a picture like the one below. Especially during the summer, people are more likely to think about tents than measuring round parts. I, however, can’t stop thinking about round parts!

There are many different strategies for measuring round parts. From basic touch trigger CMM’s, entry level roundness or form checkers, to scanning CMM’s, and all the way to dedicated high-end roundness checkers. Instead of just focusing on form, many times these parts have dimensional features that need to be checked. Ideally, one machine could measure everything.

Examples of round parts encompasses a wide variety such as, shafts, cylinders, and housings. These are just a few varieties of the round part family and they have different GD&T callouts as compared to prismatic parts.

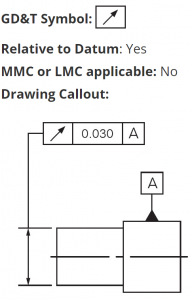

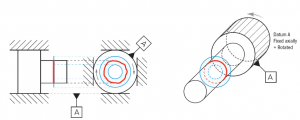

Consider Runout – (Resource – GD&T Basics)

“Runout is how much one given reference feature or features vary with respect to another datum when the part is rotated 360° around the datum axis. It is essentially a control of a circular feature, and how much variation it has with the rotational axis. Runout can be called out on any feature that is rotated about an axis. It is essentially how much “wobble” occurs in the one part feature when referenced to another.”

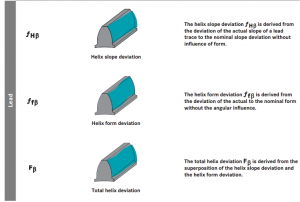

Gears present a challenging metrology task in that they are rotational parts and that they have a feature, teeth, that need to be checked with their own unique considerations.

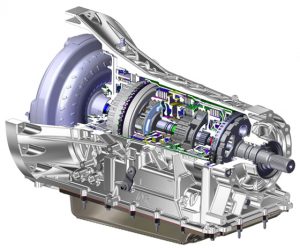

For example, looking at a transmission, you can see a number of parts that are clearly in this family. Additionally, when you think of transmissions, you naturally think of gears.

So checking gears could be considered near the pinnacle of challenging parts to measure. They encompass all the rotational characteristics that are important, as well as the unique feature of teeth that need to be checked.

While all gears do not have tolerances that are tight, we can safely say that the tolerances for gears going into automotive transmissions need to be fairly high tolerance because of the immediate feedback the end user experiences, noise, feedback and performance.

So checking gears, instantly rules out all roundness checkers because they cannot measure teeth. It rules out a touch trigger CMM, because not enough data is collected for the roundness measurements. It leaves scanning CMM’s and dedicated gear checkers.

Enter the Wenzel WGT Family of instruments

What if you could have a instrument that could check all the rotational features that are called out on your part as well as some dimensional features?

Features such as, Diameter, Distance, Axial and radial run-out, Perpendicularity and parallelism, Roundness, Flatness and straightness, Accumulated run-out (axial and radial), Position, Concentricity and coaxiality, Symmetry, Cylindricity, Run-out of interrupted contours.

What is interesting about these characteristics is on a traditional roundness checker it cannot measure a simple diameter out of the box. While a roundness checker can give you very accurate results on all of the roundness characteristics, adding the capability to measure diameter usually entails a special engineered solution or a huge jump in price. These instruments are not built as multi-purpose measuring tools, rather they are for the most part dedicated to a specific task.

A WGT is built from the ground up with our knowledge on how to make 3-axis coordinate measuring machines. What does this mean to you? It can handle ALL the measurements your round parts require + it can measure gears.

The WGT family uses a scanning probehead to take hundreds, if not thousands of points. So you get all the advantages of CMM scanning. With a simple add-on it can also measure surface roughness, as well being able to detect grinding burn.

Another important consideration is the rotary table capacity. In some CMM solutions, it is an afterthought. At Wenzel we realize that it is integral to measuring these types of parts. The capacity of the two types of rotary table are: the pneumatic goes up to 3,000kg, diamter of 750mm, the hydrostatic up to 30,000kg, diameter of 1800mm.

Gears +

To summarize, a WGT is not just for measuring gears, it provides answers to multiple metrology questions.

Also, if you need to measure something, slightly larger, and it’s round, we have answers for that too. Search for Wenzel America or the Wenzel Group and find pictures like those below, instead of tents.