Delivering true 21stCentury Multi Sensor Capability with Intrinsic Accuracy

- What if you could have a fully articulable, ultra-fast optical sensor on any CMM Coordinate Measuring Machine in your shop that fits right in your standard Renishaw change rack?

- How much time would you save by moving from a Renishaw SP25 sensor to a laser line scanner just like you do between two different length touch probes?

- Imagine measuring the contours of a body panel or hip joint with a complete 3D surface map using a laser, then measuring the geometric features with a touch probe – without moving the part.

High measuring throughput and large measuring range

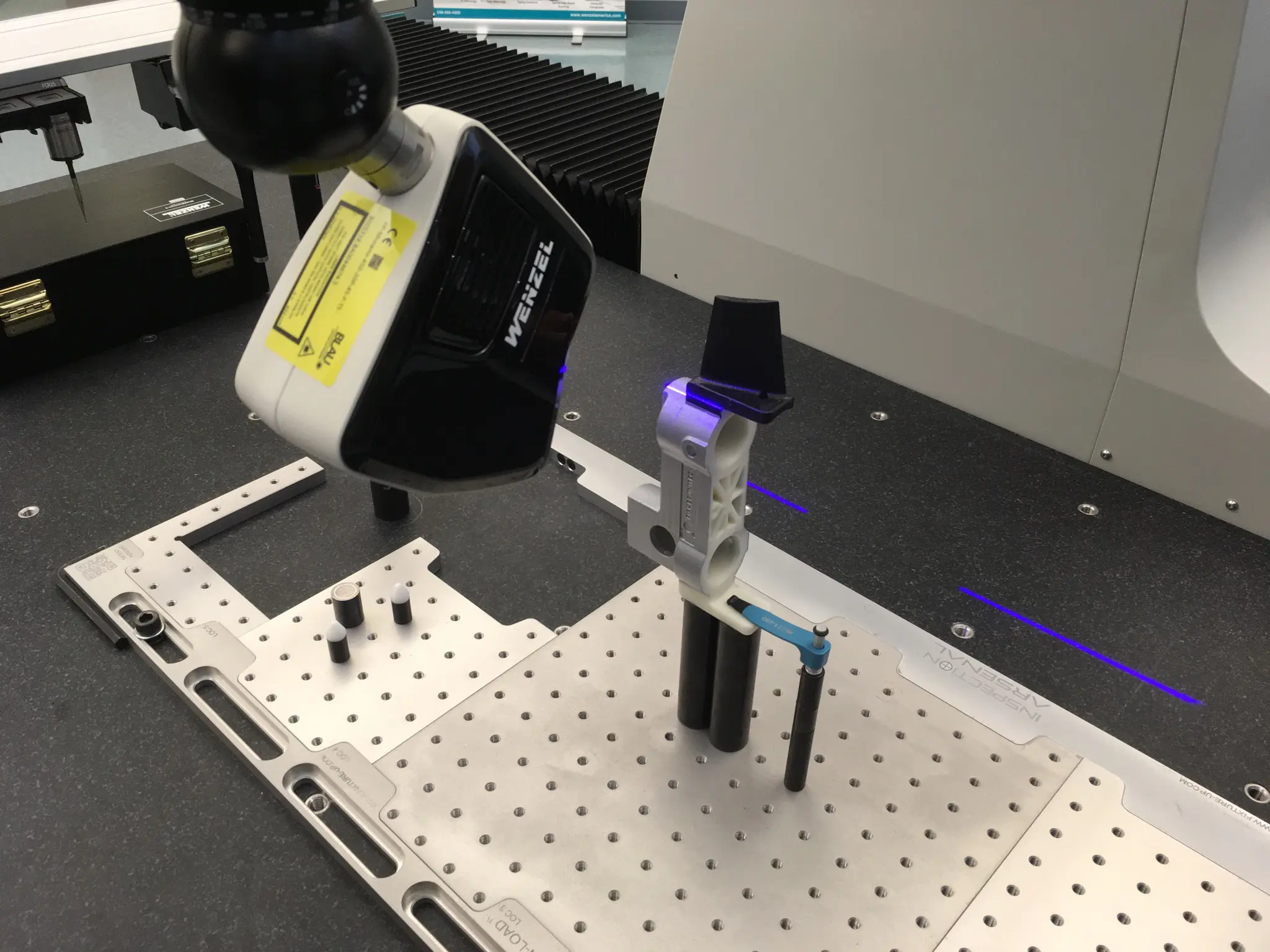

The Wenzel SHAPETRACER II offers a short stand-off distance of only 90 mm and a working range of 120 mm. Compared to the market these are outstanding values. Because the sensor scans very close to the workpiece the measurement range is used optimally.

As a result the Wenzel SHAPETRACER II is ideally suited for testing small parts, as well as for the measurement of large-volume components. Through the use of a blue laser line and a better resolution, a higher tolerance against critical surface structures has been achieved.

By using a lens and ambient light filter the WENZEL SHAPETRACER II works independently from external light and has great flexibility for scanning differing workpiece colors.

Multisensor operation for effective measurement

By adapting the Wenzel SHAPETRACER II to the PH10 motorized indexing head from Renishaw, the sensor can carry a range of probes and extensions and can be orientated in 720 repeatable positions, giving access to the most difficult-to-reach workpiece features. Because the calibration data of the 3D line scanner are stored on a smart camera system, the installation is very easy.

The connection to the coordinate measuring machine is done through a fully integrated multi-sensor interface. The possibility of multi-sensor operation of optical and

tactile measurement guaranteed effective work is for every application.

Various Digitizing and measuring applications

The Wenzel SHAPETRACER II is driven by the PointMaster software package. Wenzel PointMaster has a modular structure and includes functional modules for reverse engineering, measurement and evaluation and iterative tool compensation. Firmware updates can be loaded easily through a sensor which is mounted at the autojoint. The Wenzel SHAPETRACER 3D line scanner changes a coordinate measuring machine into the ideal tool to record and handle point clouds. Perfect for tool and die making, design model construction and anyone who needs to record and work on surfaces and outlines of physical objects.

It’s not only possible, we will customize a system to fit your exact CMM Coordinate Measuring Machine needs. By implementing the Wenzel SHAPETRACER 3D line

scanner sensor alongside your SP25 on a PH10 head you have metrology versatility like you’ve never experienced.

Coordinate Measuring Machine Redefined

The SHAPETRACER 3D line scanner sensor fit on the Renishaw PH10 just like a regular touch probe. Used in unison with the Renishaw SP25 and you’ve got a Bridge

CMM Coordinate Measuring Machine that can do what no other machine can do.

You’re not forced into buying more granite than you need.

No need to compromise your measurement needs because the only optical sensors they make are fixed downward.

With Wenzel America you get a custom all-granite CMM coordinate measuring accuracy with full axes measurement, speed, and fully articulable. We provide true 21st century MultiSensor capability plus a tradition of only the most metrologically accurate material.

Contact Us to learn more.