Wenzel launches new XOplus Coordinate Measuring Machine

Usually, in this column we take you inside the metrology and 3D measurement machines, tools, and technologies of our partners and customers. But this month we’re pretty excited to take you under the surface of the newest edition to the Wenzel family – Our new XOplus Coordinate Measuring Machine series.

This new line of Wenzel CMMs is produced in our recently expanded Wenzel Shanghai production facility by Wenzel craftsmen and builds on the popularity and versatility of our XO CMMs. The German-engineered and designed XOplus bridges the technical and commercial gap between the standard XOrbit line and our flagship, German-designed and built, LHG CMMs.

New CMM sizes mean even more precision solutions

Finding the precise size/accuracy/price CMM combination will be even easier since the XOplus size options differ from our XO and LHG lines. The XOplus range includes bridge sizes of 55 (500mm by 500mm), 77, and 98. Each bridge size also has different Y-axis lengths, making for exact and custom Wenzel measuring solutions for whatever measuring task you have.

XOplus CMM Add It Up. +Accuracy +Protection +Scanning

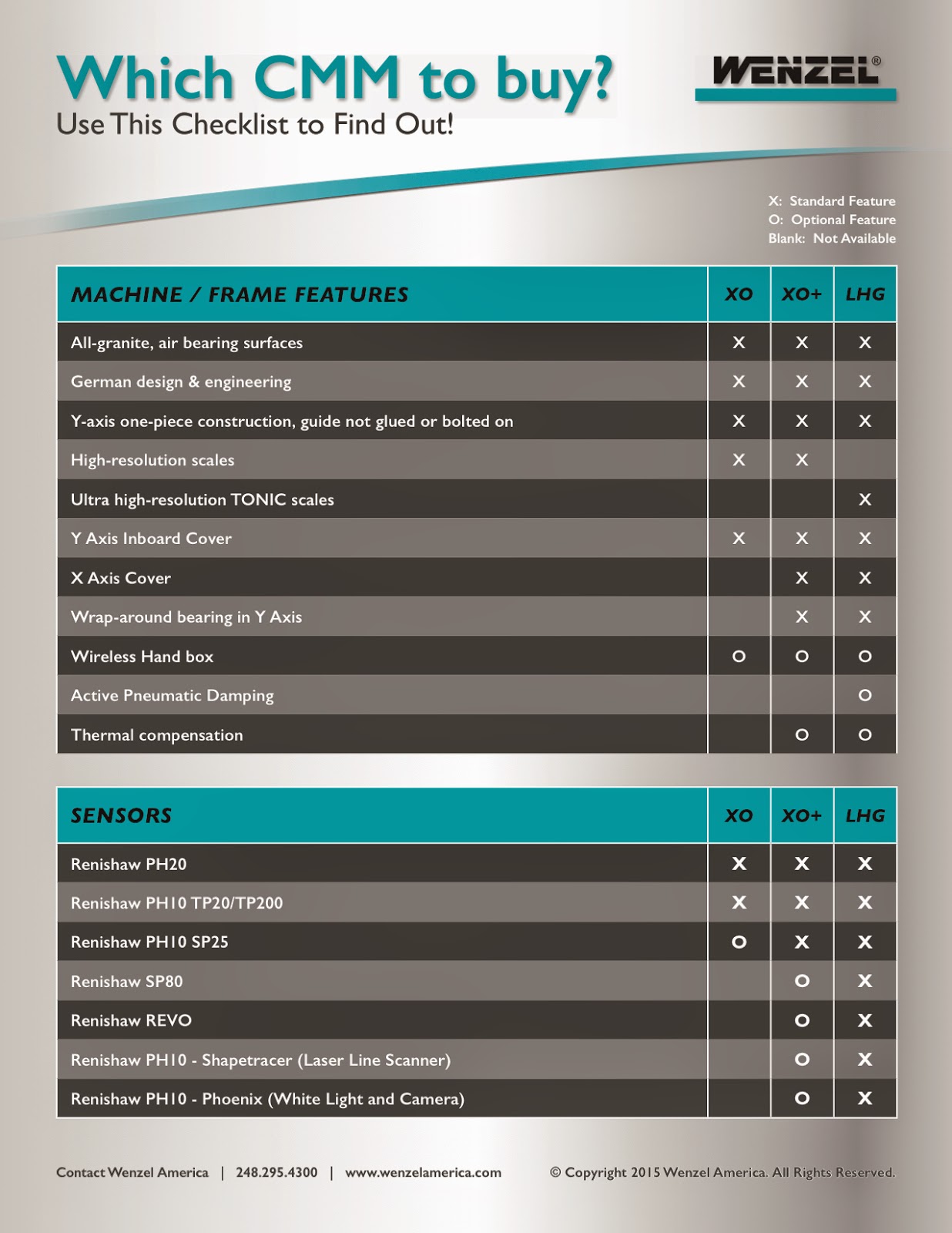

When looking at the XOplus versus the XO CMM lines there are three technical reasons you may want to choose the XOplus.

- Accuracy – XOplus offers higher accuracy than the regular XO line.

- Protection – XOplus has an X-axis cover, the XO does not.

- Scanning – XOplus uses smooth tooth belt drives allowing for higher speeds and smoother 3-axis scanning

Design improvements bring two more pluses to the table

There are two main design improvements in the XOplus series that give these CMMs higher measuring accuracy than the robust XO CMMs.

The first of these relates to the X-axis of the measuring machine:

The XOplus has a belt drive system similar to those used on our LHG machines. You can see it below enclosed in the new concertina covers.

The second thing we did was improve the Y-axis bearing arrangments. Placing the two additional bearings and extra bearing way against the lift bearings on top of the plate adds extra stiffness to the machine structure, delivering improved accuracy.

The XOplus incorporates two additional wrap-around air bearings both acting on a newly added, hand-lapped, and ground guideway on the underside of the one-piece Wenzel CMM plate.

Accuracy, precision, and stability at every level

The new mid-range XOplus CMMs perfectly round out the accuracy/price/size gaps between the XO and LHG. But, because all our machines combine precision engineering and the most stable metrology material, how much machine you really need for your measurement needs is not always obvious. We’ll soon be publishing a comprehensive Bridge CMM buyer’s guide to help fill the knowledge gap between what your needs are and which machines best meet them.

More Information about the XOplus CMM

For more information about the Wenzel XOplus CMM series you can get the full scoop along with a downloadable product data sheet on the website. To get all your questions answered about the XOplus and find out when you can take delivery, please call Wenzel America at 248.295.4300. For more information and a related story on the new Wenzel Shanghai production facility where the XOplus is made check out this article.