Wieland’s primary focus has always been Quality Assurance

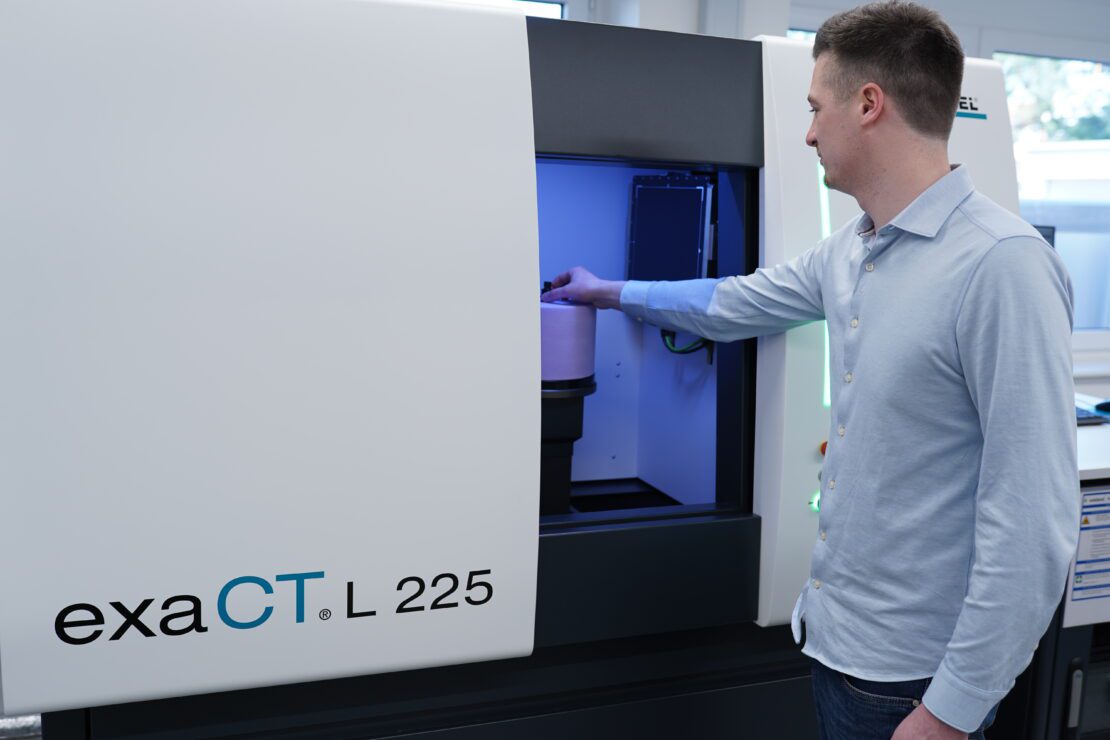

WENZEL’s team visited Wieland Electric in Bamberg to share how a company that was started in 1910 has raised its quality assurance processes to new heights with the WENZEL exaCT L computer tomography machine. Naturally, in a rich history of over 100 years there have been changes except for their focus on quality.

Wieland and WENZEL stand for quality Made in Germany, and both have the guiding principle of “Tradition meets Innovation”. Starting in 1910, Fritz Wieland laid the foundation for the company with his slotted terminal, the so-called Wieland terminal. Today Wieland Electric guides customers from project planning to project completion with the Wieland terminal primarily used in the Building Solutions and Industry Solutions business units.

WENZEL’s Computed Tomography takes you to the next level.

In over a hundred years of Wieland’s existence, there have been several changes. From component supplier to solution provider, Wieland has always evolved but the focus has always been on quality and product assurance.

The innovative, watertight connectors had to be embedded, sawed, grounded, polished and then checked for quality. Before Wieland invested in the WENZEL CT, they were using 2D measuring microscopes which was a timely process. With the exaCT L 250 from WENZEL, quality assurance could be raised to new heights.

Typical defects in plastic components such as blowholes, material distortion or even material accumulation in undesirable places are not uncommon and must be eliminated before further processing.

With the CT from WENZEL, these defects can be detected immediately by non-destructive testing of the plastic parts. This enables Wieland to check the quality of its products quickly and easily. By target/actual comparison, the parts are analyzed by the CT, and their quality is evaluated.

COMPUTED TOMOGRAPHY ADVANTAGES

- Non-Destructive analysis of your part inside and out.

- Material integrity analysis.

- Internal and external measurements.

- Reverse engineering

- Wall thickness analysis

- Assembly Verification

- Quality Inspection

Precise measurement results at the push of a button

The WENZEL CT is characterized by its intuitive user guidance. As demonstrated in the case of Wieland. Testing processes can be carried out non-destructively and, above all, in a fraction of the time previously needed for testing. In its performance class, the exaCT L 250 is one of the most compact on the market. It has three independent axes and offers splendid X-ray performance. With its hardware and software, the exaCT L 250 can be easily integrated into the production line and thus provides market-driven answers to questions relating to Industry 4.0.

About Wieland Electric

We are a solution provider and world market leader for pluggable electrical installation in building technology and a supplier of safety and automation technology. In over 70 countries worldwide, we serve customers in the fields of mechanical engineering, wind energy and building and lighting technology.

For more than 100 years, we have been developing solutions and manufacturing components that are precisely tailored to your application and requirements. (Learn More…)

INDUSTRIAL CT SCANNING MACHINES BY WENZEL

Our Industrial Computed Tomography scanning machines open a whole new world of metrology and offer much more capability than a laser scanner or white light scanning system.

What distinguishes our CT scanning machines from our competitors is their ease of use by engineers and quality staff not previously experienced in radiography or X-Ray technologies. These systems seamlessly integrate with metrology and other quality applications, are compact and can be safely installed in an office, lab or on the shop floor as part of your quality assurance process.

Contact WENZEL America for more information: sales@wenzelamerica.com or visit our website.