In my last article I outlined examples of how the Renishaw REVO has revolutionized CMM inspection. While it is true that 3 axis CMMs are quickly being replaced by a mature 5 axis REVO, there still are a few customers that have been hesitant to trust the hype. These customers are worried that new technology is expensive, and without support, the implementation of the REVO will be time consuming and difficult to use. True for anything unfamiliar, these customers just need the right person to lead the way.

In my last article I outlined examples of how the Renishaw REVO has revolutionized CMM inspection. While it is true that 3 axis CMMs are quickly being replaced by a mature 5 axis REVO, there still are a few customers that have been hesitant to trust the hype. These customers are worried that new technology is expensive, and without support, the implementation of the REVO will be time consuming and difficult to use. True for anything unfamiliar, these customers just need the right person to lead the way.

Customers need a qualified person to make management trust their purchase. They need a teammate to work with their quality professionals. The employees in the quality lab need to know, when they choose Revo, they will have the training and support they need, to be successful. At Wenzel, our application department will back you up. In fact, we have a person uniquely suited to make you trust in your decisions. We have the person who helped write the DMIS book on 5 axis measurement, Henri Bosch.

For those who don’t know Henri, He has been in the quality business for a long time. He started supporting and servicing CMMs in 1990. From 1996 to 2002 Henri managed applications and Engineering at International Metrology Systems. In 2002 He was a founding owner of Xspect solutions where he was the VP until Wenzel bought Xspect in 2008. Since then Henri has worked with Wenzel America providing Software Engineering, Applications Support, Programming Services, and helping to grow our team of REVO specialists.

For those who don’t know Henri, He has been in the quality business for a long time. He started supporting and servicing CMMs in 1990. From 1996 to 2002 Henri managed applications and Engineering at International Metrology Systems. In 2002 He was a founding owner of Xspect solutions where he was the VP until Wenzel bought Xspect in 2008. Since then Henri has worked with Wenzel America providing Software Engineering, Applications Support, Programming Services, and helping to grow our team of REVO specialists.

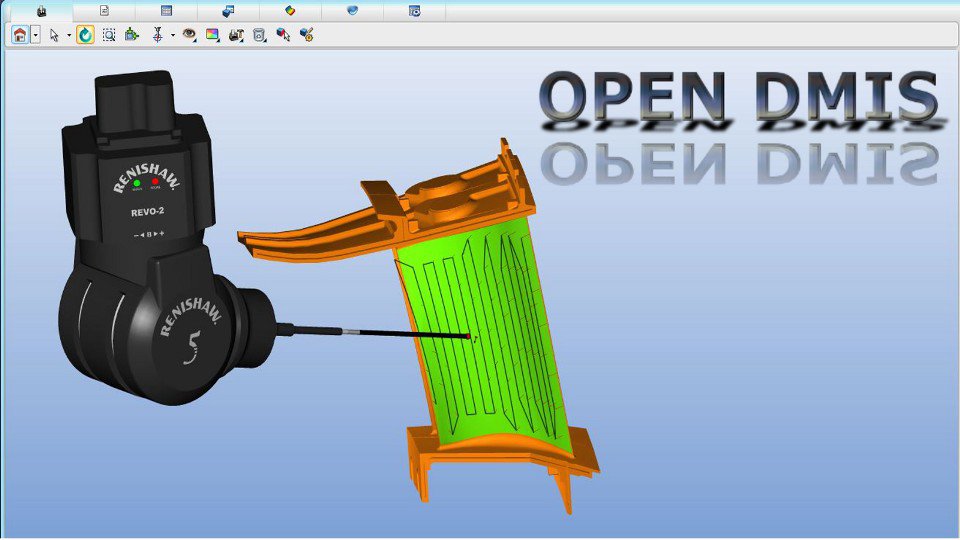

I wanted to know more about why Henri is so good at supporting REVO, so I interviewed him about his past. What I learned is Henri was a forerunner in developing DMIS for 5 axis systems, helping to develop the foundation which these products stand on today. For those of you that don’t know, DMIS is the Dimensional Measuring Interface Standard, and it provides a set of rules to allow a software to interact with a machine controller, in order to collect measurement data. You can learn more here.

Henri Started his work with the DMIS standards committee in 1991. For context, the fastest PCs in 1991 were running DOS, on Intel’s 486, and DMIS version 2.1 was accepted as an American National Standard. From 1991 to 2006 Henri worked with the DMIS standards committee to continually improve the DMIS standard as more CMM manufacturers adopted DMIS.

Around 2006 with the REVO on the horizon there became a need to introduce 5-axis to DMIS. Henri began developing DMIS  instructions for 5 axis measurements with his colleagues at the DMIS standards committee. “Back then there was no such thing as 5 axis measurement.” Henri continued “The DMIS standard needed to be updated with definitions for new measurement techniques like sweep and gasket scans.” While Henri is part of the software team for OpenDMIS, all his efforts developing DMIS were in support of the whole industry. His work on the DMIS standard is what allows us to take advantage of these powerful measurement tools today.

instructions for 5 axis measurements with his colleagues at the DMIS standards committee. “Back then there was no such thing as 5 axis measurement.” Henri continued “The DMIS standard needed to be updated with definitions for new measurement techniques like sweep and gasket scans.” While Henri is part of the software team for OpenDMIS, all his efforts developing DMIS were in support of the whole industry. His work on the DMIS standard is what allows us to take advantage of these powerful measurement tools today.

Coupled with his extensive metrology background, Henri’s deep knowledge of DMIS allows him to simplify, and execute what otherwise might be very complex customer applications. This allows him to quickly and easily help customers take advantage of the tools and productivity that 5 Axis Metrology has to offer. Am example of the was the implementation of the torus feature into the DMIS standard. Henri working with a customer who needed to measure a torus, but this feature was not included into DMIS. Because of Henri’s direct path and ability to bridge the practical with the abstract, he was able to implement the torus request into the standard quickly, helping the customer and the industry.

My biggest takeaway from my interview with Henri is this: The key to success is making the transition to REVO easy. Henri stated:

“Most of the hesitation I find with new users of REVO, comes from a perceived complexity. New hardware can look challenging but the REVO is much easier to program than any other indexing probe head. It is easier for two basic reasons. The first is the REVO automatically adjusts to the part position once the part is aligned. Meaning fixturing the part exactly is not critical, which makes planning your tooling much simpler. The second is the combination of unlimited head and bridge movement leads to programming your moves and measurements in more efficient paths, all while not worrying about what angle to use.”

“Most of the hesitation I find with new users of REVO, comes from a perceived complexity. New hardware can look challenging but the REVO is much easier to program than any other indexing probe head. It is easier for two basic reasons. The first is the REVO automatically adjusts to the part position once the part is aligned. Meaning fixturing the part exactly is not critical, which makes planning your tooling much simpler. The second is the combination of unlimited head and bridge movement leads to programming your moves and measurements in more efficient paths, all while not worrying about what angle to use.”

What does this mean for you? It means that we have the ability, experience, and knowledge to support you the customer in making the transition from traditional 3 Axis Metrology, to the productivity, power, and simplicity that REVO and 5 Axis Metrology have to offer. As a potential Wenzel customer, I want you to know that we will bring the 5-axis hero you need to thrive in the REVO world.

Why not cut your measurement time by up to 80%? And why not work with the team that helped write the book on DMIS? We have the right person to make you successful with your purchase. We have Henri Bosch.

In the third and final part of my series, we will look more in depth at how REVO saves you time and money and help you measure #morepartsfaster .