Do you need a measuring solution for your high-volume shop floor production cells but nowhere near the budget for 10 new CMMs?

- What if you could have a single CMM coordinate measuring machine do the job of 10?

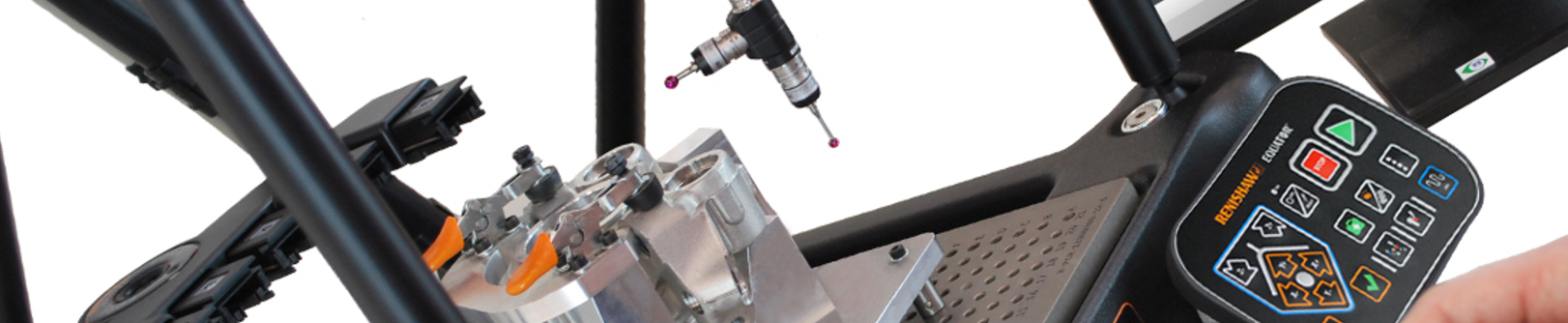

- What if instead of getting 9 new CMM coordinate measuring machines you could purchase 10 Renishaw Equator gaging systems and 1 Wenzel CMM coordinate measuring machine for 1/10th the cost?

- What if this solution measured all the parts you needed even faster?

We’ve created the metrology system that can do exactly that. We call it the Wenzel Meridian system.

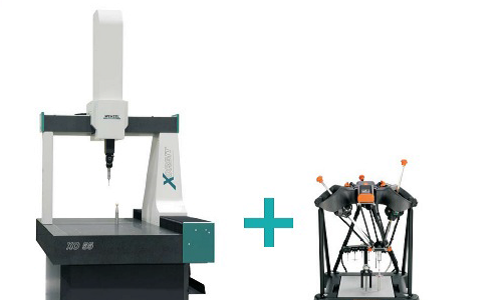

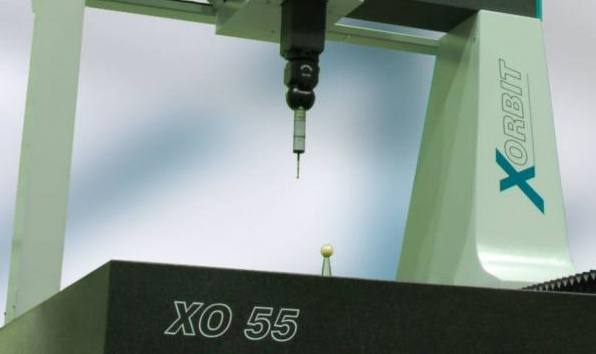

It combines the intrinsic accuracy of the XO55 CMM coordinate measuring machine with the unmatched precision and versatility of Renishaw’s Equator gaging system.

Our latest innovative metrology solution allows you to make master and golden calibrations more quickly and accurately. You get increased production speed and customizability that is perfect for high-volume shop floor production cells.

We’re not intimidated by using other people’s software on our machines. We have incredible software, but our goal is to build systems that do the measuring jobs you need. Precision metrology is what we do, tethering you to a less than ideal solution simply compromises our integrity. Creating new systems with our granite CMM coordinate measuring machines and metrology expertise at the foundation means we can always deliver the best leading-edge measuring solutions every time.

Renishaw’s Equator versatile gage uses their MODUS software and so we developed the Meridian system with XO55 powered by MODUS. Meridian brings full compatibility and traceability to shop floor gaging. The increased production that results is easily handled by adding an additional Equator anywhere in the production line.

When we outfit you with a Meridian system we install both components, the XO55 and the Equator, plus we train you on the Renishaw MODUS software that powers both machines.

Contact Us for more information or to learn about Wenzel America.