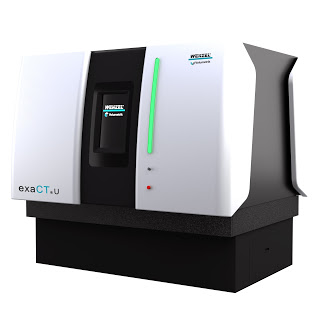

If you were looking for a CT solution that is the right size for your parts and fit on your desk, then you are already familiar with WENZEL’s “exaCT” line of computed tomography products.

Like the “WENZEL exaCT S” shown here, these solutions make great business sense for the required results and using the machine day to day.

No matter your specific need whether it is structural analysis, assembly control or internal defect analysis we believe we have the non-destructive testing solution for you. In keeping with WENZEL’s ability to provide customized solutions to fit you and not the other way around, we have introduced the exaCT U.

Computed Tomography machine tailored to your needs.

The customer can tailor this machine to get exactly what he or she needs versus compromising their application on only what a manufacturer provides. How can WENZEL provide you with this tailored solution?

Easy, the exaCT U was designed from the start to accommodate each system with the appropriate X-ray source and detector. It includes four independent traversing axes, and it offers an impressive resolution (4000 x 4000 pixels).

What does that mean for you? You can select a source power of 135-450 kV. Additionally, the new exaCT-U has a much larger measuring volume of 700mm (27.5 in) height and 300mm (11.8 in) in diameter. This allows for larger parts and even higher densities than previously offered on the exaCT M and S offerings.

What good is all that technical power if you cannot get to the data? Well, WENZEL has addressed this as well. WENZEL’s interface optimizes the ability to obtain precise measurements after just a short training period. That means you are up and running, faster and providing vital data sooner, providing a quicker return on your investment.

Utilizing the experience, we have gained from measuring thousands of parts we have developed algorithms that automatically optimize the measurement parameters. This is a key feature in getting you up and running faster.

Another factor that goes into this better, faster, stronger data acquisition is the fact that the CT control and reconstruction software is developed in house by WENZEL.

The hardware and software can be tightly integrated to be optimized and fine-tuned. The advantage for you is that the data acquisition software ensures the optimized control of the computer tomography with the reconstruction software guaranteeing the exact calculation of the volume data.

The evaluation software of the exaCT U can be handled by QUARTIS and exaCT Analysis. A single measurement provides numerous evaluations such as:

- Material testing

- Nominal-actual comparisons against a master component or CAD data

- Reverse engineering

- Compensation of shrinkage and warping

Are you ready for the next generation exaCT U? One of the perfect applications are doing nondestructive testing on additive manufactured parts. The advantages of printing parts let manufacturers design geometries that are not possible with subtractive manufacturing.

A problem quickly arises because how can you check, or evaluate these parts as compared to the CAD or drawing? With the exaCT U, now you have even more possibilities to do this and on much larger parts and more dense materials than in the past.

Now you can print your parts in whatever complex geometry you can imagine or that your application demands, and the WENZEL exaCT U will be able to measure and analyze them.

Our Measurement Solutions for your Quality Assurance

We offer a comprehensive range of industrial computed tomography systems for the measurement and non-destructive inspection (NDT) of complex internal and external structures, which are also ideally suited for automation.

The compact entry-level solution is the exaCT S CT system. The 3D X-ray system fits on any desk and offers high performance in the smallest space. The exaCT M CT measuring system is based on a workstation concept with integrated evaluation unit and is suitable for small to medium-sized components.

The exaCT L series is extremely flexible and offers high X-ray performance for all industrial computed tomography applications. The CT system offers a simplified, cost-effective and fully automated workflow for the entire CT analysis process. The universal exaCT U is the most powerful industrial computed tomography system in our portfolio with a large measuring volume.

For more information visit www.wenzelamerica.com or email us at sales@wenzelamerica.com.