The future is on my mind. In my past life, it never seemed to be *that* worth focusing on or planning for. Working in Aerospace, our tagline was “it’s late 80’s tech”, while in the quality dept of a machine shop, there was only concern for the parts in front of us, and even in my personal life “it’ll work out” or “whatever happens, happens” were often the prevalent thoughts.

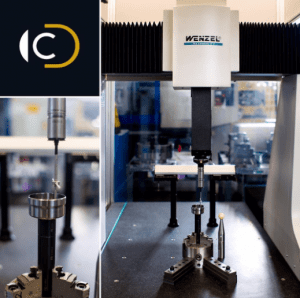

All changed when I joined Wenzel America last September. Suddenly, “the Future” was driven to the forefront of my mind by working with cutting edge technology, and passionate people.

The Future is demanding much more attention – technology, training development, relationships, culture…. and even industry.

The Fourth Industrial Revolution – The future of Industry or Industry 4.0 has been an unforeseen theme for me over the last 6 months and today, Wenzel America exhibited some of our own technologies at the Automation Alley “Technology Outlook” event at the Detroit Institute of Arts.

Surrounded by beautiful artwork, some of it centuries old, “the Future” (and how it affects them) was on everyone’s mind.

The event featured a great networking session, and ended with a Technology Industry Report and an open panel discussion on Industry 4.0 with companies at the forefront of the revolution.

The benefits of using ‘Big Data’, supply chain streamlining, circular economy effects, and (somewhat surprisingly) the immense struggle to find enough qualified people to fill the employment need, were all things that were discussed at length. “But why should I care about all of this” asked one of the students in attendance, which prompted the room to laughter. I don’t think the student saw the irony in the question….

At lunch, Drew (Current President of Wenzel America) asked the familiar question “Why do we walk out of our social life, into our work life…. And leave the technology behind?”. Once again, I didn’t have an answer. We live in a social environment that is overwhelmingly interconnected. Information crosses multiple websites for marketing, Facebook listens to conversations, apps left and right are communicating and sharing to grow your “network” and improve your connections.

Data matters when WE are the product, shouldn’t it matter when we manufacture products too? What if your oven told you when the element is close to burning out? Or your CNC Mill knew that the machine tools needed to be replaced? Or your CMM not only told you that your drive belts need replacing…. But actually ordered them for you? That’s the Revolution.

The Wenzel Group is fully committed to an Industry 4.0 future and bringing new and innovative metrology solutions to support the manufacturing world. For our part here at Wenzel America, we will continue our dedication to providing flexible and innovative metrology solutions and assisting (or facilitating) the implementation of automation and other Industry 4.0 needs.

We are also striving to grow awareness and exposure of manufacturing, here in Southeast Michigan, and across the USA through several different projects, and involvement with organizations such as Automation Alley.

The launch of our Instagram/Blog customer feature, offers a window into the huge breadth and great capabilities of manufacturers here in America, and offers a chance for their story to be told and shared with people who otherwise may not even be aware they exist.

Manufacturing Day 2016 provided us an opportunity to inspire the next generation of workers, and demonstrate an industry that many of them didn’t even know existed! It was a great event, and we will be looking forward to providing similar opportunities throughout 2017.

For the customer feature visit: www.instagram.com/wenzelamerica

and look for our quarterly blog posts.

To be featured contact SNichols@wenzelamerica.com

Click on the link for our MFGDay16 review.

I’m excited about our future, and I hope you are too.

Stuart Nichols

Applications Manager For those of you that may not have heard about Industry 4.0 here’s an excerpt from Automation Alley’s Tom Kelly.

“Industry 4.0 is the marriage of the physical world and the digital world. It’s a concept that got its start in Germany, and it’s now becoming part of the manufacturing conversation around the world, but so far it’s been slow to catch on in the U.S. In this new era of making things, sensors at every step of the manufacturing process provide manufacturers with real-world data. This can be used to create models and run simulations in the digital world, allowing for continuous improvement, significant cost savings and a myriad of other benefits. In an Industry 4.0 factory, or “smart factory,” machines, devices, sensors and people are all interconnected and can communicate with each other. Digital systems work both autonomously and in collaboration with humans.”