Have you ever driven a car? Ever used an elevator? What about watching the wing flaps move up and down while staring out the window on a boring flight from Detroit to Des Moines?

Whether you know it or not, these things all rely on gears to translate forces into rotational motion.

The list doesn’t stop there.

That electric toothbrush… The one you used this morning…

That has gears too.

So does the coffee grinder you used to make that fresh pot of joe. The automatic door you walked through at the gas station? And the gas pump you filled up with a few minutes later? Escalators. And even your microwave.

Yep, they all run with gears as well.

Almost all the electro-mechanical devices around us use gears to get the job done. Gears literally drive our world. They are actually a fascinating topic to explore.

With so many different types of gears where do you start?

Well, it’s research right? So, let’s start with the gear entry on Wikipedia.

Not bad for Wikipedia. There’s quite a bit of good, reliable info here and it shows how broad the topic of gears can be. Just from there you can see the many different shapes of gears and different applications.

One of the most practical aspects you see and use daily without thinking about it are the hundreds of gears at work in your car.

Check out this 1937 video produced by Chevrolet on the gearhead blog, Jalopnik:

It’s probably the best and simplest video ever made on how car differentials work.

With so many types of gears and gear applications, how do we keep things straight?

How do gear makers ensure that the products they design, produce, and deliver are of the quality, consistency, and performance the application requires?

How do manufacturers, machine tool shops using gears in their process ensure the gears they buy will work for the application they need?

Standards.

Like most modern manufacturing industries, the Gear Industry has their own standards organization called the American Gear Manufacturers Association. Founded in 1916, AGMA is a member and market-driven organization that conducts programs and provides services to the gear industry and its customers.

AGMA does everything from technical training to the development of standards and practices for the industry. To learn more visit the American Gear Manufacturers Association.

What does this have to do with a Coordinated Measuring Machine manufacturer?

More than a decade ago we took the same principles of mechanical accuracy, precision, and quality that go into our CMMs and applied them to gear metrology in our Geartec systems. Starting with the same solid base of granite, we manufacture a complete line of gear inspection machines for all types and sizes of gears.

Then a couple years ago we took another step by joining forces with gear hobbing, shaping, and grinding machine experts at Liebherr Gear Technology Inc., who became our exclusive U.S. and Canadian distributor of the entire Geartec line. Together, we’re dedicated to bringing gear manufacturers a new level of dimensional quality in every gear they make – from design and manufacture all the way through final inspection.

Our two companies provide machines, software, and expertise for all gears – from smallest in the home appliance market to larger gears for wind turbines and even mammoth 20 foot diameter gears.

You can learn about many of our machines by visiting the Geartec product page.

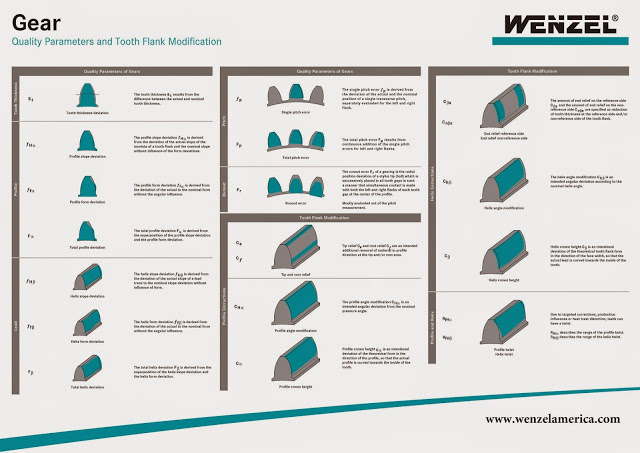

We also made a one-page reference that shows details of gear tooth geometry:

Think something looks complex? Look a little deeper

The environment we live in – the tools, technology, and products that make up our daily lives – are all made from layers that often go unnoticed and unappreciated. The supercomputer in your pocket, the gas in your tank, and even the food on your table – each of these has layer upon layer of technology behind it.

It’s a little overwhelming when you think about it – what really makes up the items that form the fabric of our daily lives?

Being an expert on all technology is not possible in the complex world we live in. But looking a little deeper sometimes makes things less complex and less overwhelming. When you do, you just might begin to understand and appreciate things like gears and all they do to drive our modern world.

For more information about gear measuring machines contact Wenzel America at 248.295.4300 or email us

info@wenzelamerica.com.