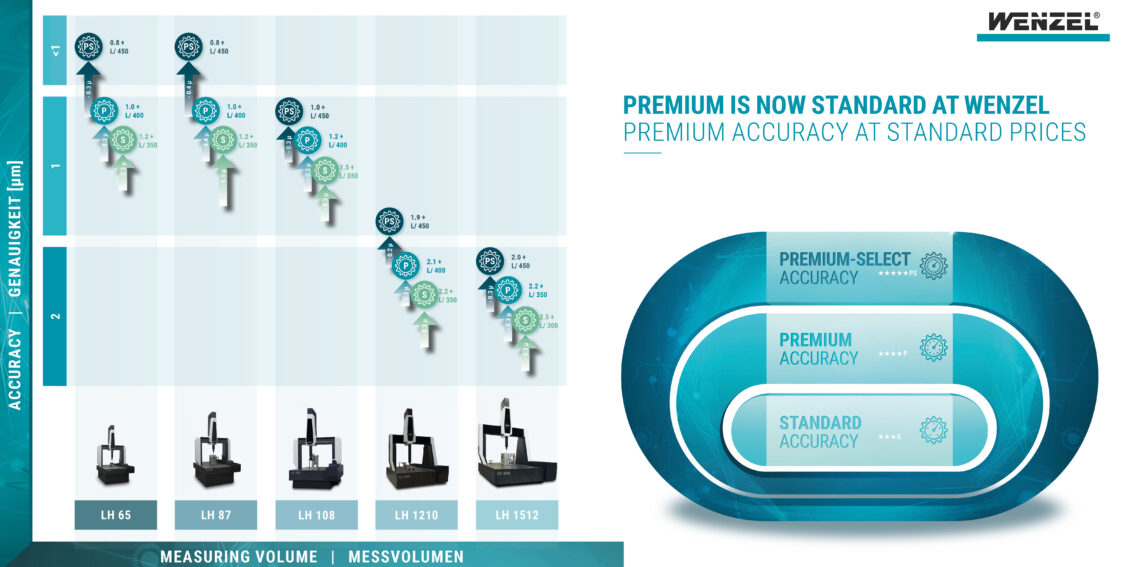

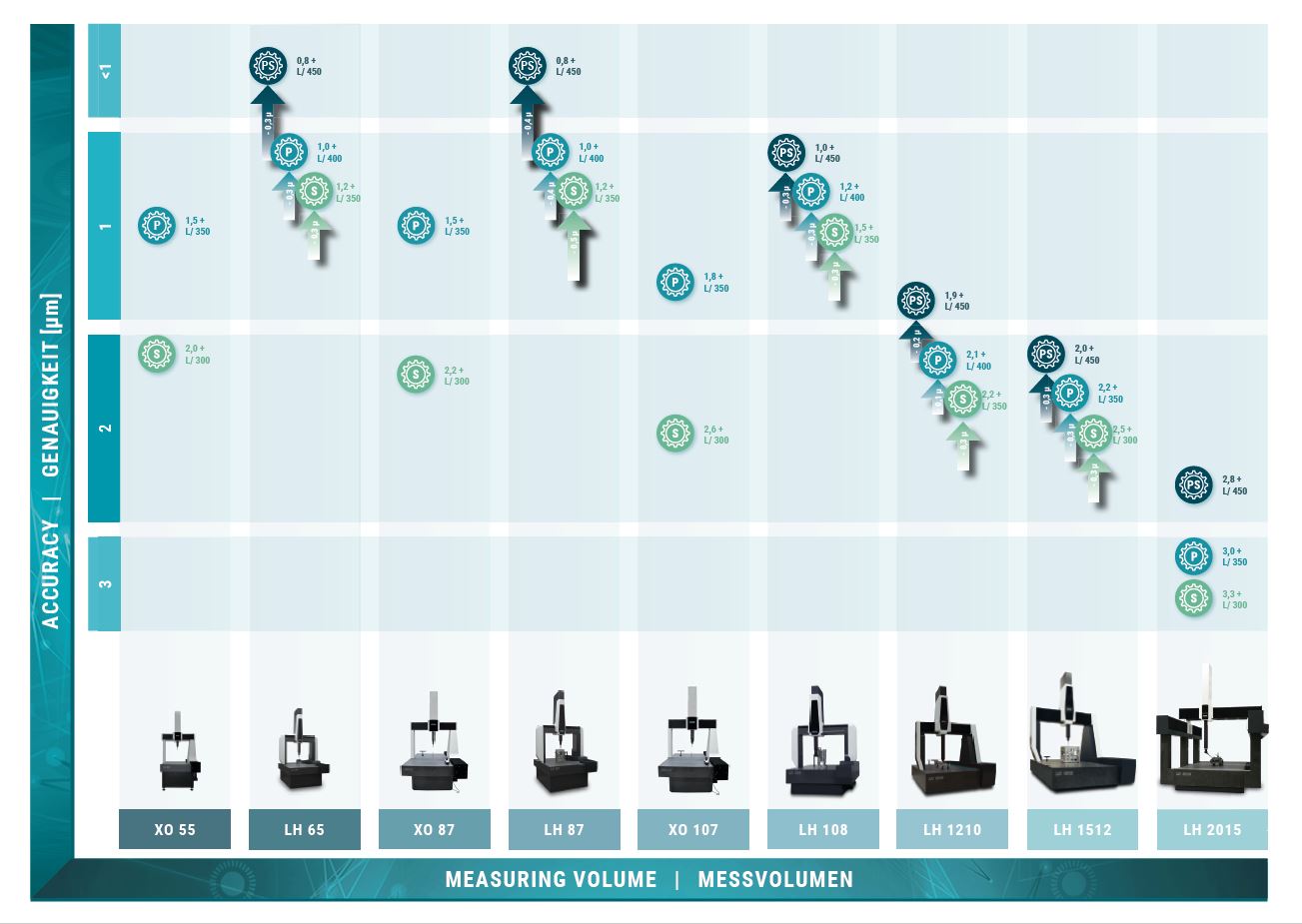

A few days ago, we proudly announced the accuracy improvements of all our LH series machines. The accuracy we previously offered as premium accuracy is now the standard. For our customers that need a high accuracy machine, this is a direct price reduction. Customers who previously purchased a machine with standard accuracy will now get a more accurate machine at no extra cost.

If you follow the press releases of other manufacturers, you can read a lot about new optical sensors and software features. The major trade fairs in September/October are approaching and we all want to demonstrate our innovative strength. Of course, we at WENZEL will launch new software versions again in autumn. In the WM | Quartis release “R 2019-2” we will see many innovations, among other things as well as a clearly improved functionality for integration of optical sensors into our automatic measuring procedures. It goes without saying that we will be presenting a new line sensor. With the WM | LS 600 we are opening up new fields of application for our machines to our customers with a line length of 600 mm. A great team effort is responsible for this and we are proud that we are also bringing competitive solutions to the market in the areas of optical metrology.

As a traditional machine builder the achieved improvements in accuracy mean something special for us. This is not due to a technological leap, but to WENZEL’s knowledge in all phases of machine development and production. Starting with the construction, purchasing, production and assembly up to the acceptance and installation of the machines. Anyone who knows and uses WENZEL machines has often asked us why we are so careful with the data sheets: “Your machines are much better than the data sheet” is a typical statement of our customers. Yes, the design of our machines has enabled us to meet the highest demands of our customers for many years. But now we have further refined our internal production, assembly and acceptance processes so that we can reliably achieve this level with every machine. And we now pass this progress on to our customers. We achieve the high accuracy through a mechanically very good and mature machine and not through lengthy, fragile compensations.

For us, a good machine is the basis for a long-lasting machine. With a WENZEL machine, we sell not only a machine, but the certainty that this machine can be used at the same level for many, many years. At a time when many suppliers tend to invest in short-lived sensors or easily replaceable software, we are consciously making great efforts and investments in hardware: the treatment of raw materials, fine machining and lapping and precise assembly. All LH machines are built by us in Wiesthal, Germany and not just assembled. Our vertical integration of manufacture is very high because we want to maintain full control over the mechanical engineering. Those who do not yet know our production facility are cordially invited to take a look at it for themselves.

Of course, our philosophy also includes first-class trained skilled workers. Not only must the design be right, but the individual components of our high-precision machines must also be manufactured and assembled very carefully. Our long-standing employees pass this knowledge on to the next generation, this is how companies work best. Just now we have a retired employee who has spent his whole working life at WENZEL: 50 years! Such employees are not only valuable, they are part of the company and its history and have accumulated incredible knowledge, which we could use for these improvements.

The progress we have made means in the end only a few figures on the data sheets; for us they are more! They show that it is worth working every day to become a little better. When experience meets curiosity and an urge to innovate, continuous improvements are made for the benefit of all.

In this sense, we at WENZEL work every day, full of joy to build even better machines.

Much fun with our machines and best regards

Heiko Wenzel