This is the first of a series of articles about the Fundamentals of 3D Scanning.

If you spend the next 5.3 minutes reading this article the least you’ll get is an education in 3D Scanning and 3D Imaging.

And you just might get enough data to inspire you to take a leap into the future of measurement and metrology that could put you ahead of your competition.

Some of what you’ll learn:

– A short history of 3D Scanning in manufacturing, reverse engineering and design.

– Understanding of the current capabilities of 3D imaging & scanning.

– A business case for widespread adoption of 3D scanning in all manufacturing.

Who am I?

My name is Giles Gaskell, after graduating from Aston University in Birmingham, England I started in “3D” images like everyone else back then – working in computer aided design. In 1995 I started my own successful CAD software consultancy. Then 1998 I discovered the first hand-held 3D scanner and surprisingly, could not find a distributor in Europe – so I became the distributor and I’ve never looked back.

Why I am qualified to talk about this ever-changing world of 3D Scanning:

– Founded the first UK Company selling 3D Scanners for Reverse Engineering & 3D Imaging.

– Expanded to Italy, servicing some of Europe’s most elite auto designers & manufacturers.

– In 2005, moved to the U.S. to work with reverse engineering, 3D Imaging, 3D Scanning companies, NVision Inc. and then Laser Design Inc.

– Since 2010, Wenzel America Applications Manager for 3D Imaging Products.

– 1 of 3 North American Advisors to SME on 3D Scanning and 3D Imaging.

– Featured presenter at SME’s RAPID show on 3D Scanning 2012, 2013, 2014.

Simply put, I have been a whole-hearted evangelist for 3D Imaging and 3D Scanning Measurement Technology since its earliest beginnings. I have seen it evolve and am excited about its future. We are at the cusp of a revolution in 3D measurement and non-contact scanning and I hope I can shed some light on its future.

What Problems Does 3D Scanning and 3D Imaging Solve in Today’s Industry?

– Solid Modeling for Product Design

– Art & Movies

– Simulation & Visualization

– Complex 3D Surface Design

– Reverse Engineering of Parts

– Legacy Parts

– 3D Inspection for Quality.

With 3D Scanning and Imaging you Can Move Physical Objects into the Virtual World for:

2D CAD

Wireframe

Surfaces

3D Graphics

Inspection Data

Haven’t We Been Creating 3D Computerized Image Models For Decades?

Sure, but let’s take a look at what is required and the results we achieve. Just 20 years ago 3D scanning did not exist in commercial use. If you wanted to get the data from the physical world into a computer model for CAD or other designing and manufacturing the metrology and measurement methods already seem antiquated:

Tape Measures

Micrometers

Height Gages

Coordinate Measurement Machines

2D Photography

2D Vision Systems

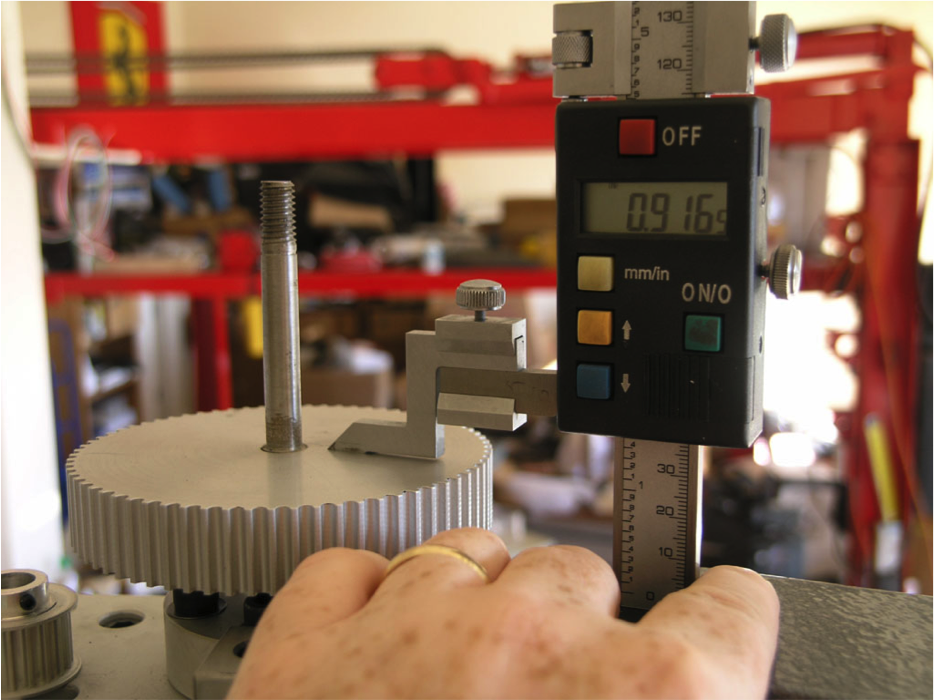

The Good Ol’ Days – Horizontal CMMs & “Digitizing” – One Point at a Time!

“High Tech” Digital Micrometers? We could be at this a little while.

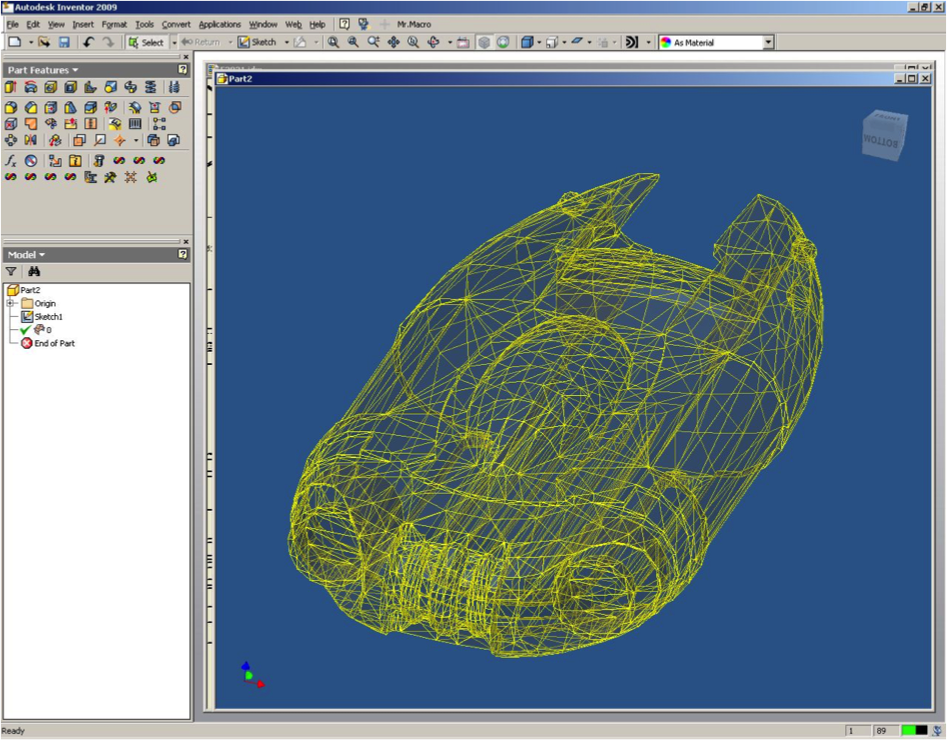

After 1000s of Hours & Relatively Few Data Points &

You Could Have a Model Like This:

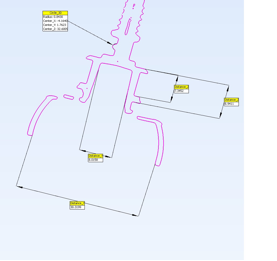

CAD Wireframe for 3D surface construction. Not bad, but not great either.

So, what is 3D Imaging and 3D Scanning today?

3D Scanning links the 3D physical world with the 3D virtual world on your computer. There is a lot of demand for it. I’ll just highlight a few industries I’ve worked with that could benefit greatly with 3D Scanning Machines and 3D imaging technology right now.

I truly can’t fathom why there is not widespread adoption in each of these areas, other than a knowledge gap in the understanding of where 3D imaging is today. I hope this article can fill some of the gap.

What Are Some Industries that Could Benefit from 3D Scanning & 3D Imaging Right Now?

Aerospace Manufacturers

The latest turbine blade designs are not only ultra-smooth and shiny they are also small and have multiple geometric surfaces that just can’t be measured with traditional metrology machines.

Medical Device Manufacturers

Whether a medical device manufacturer makes shiny replacement knees or using innovative material of varying density – the precision of measurement needed is extremely high.

And the requirements for sterility are even higher. Traditional metrological methods are quickly becoming a hindrance to development.

Plastics Companies and Plastic Part Manufacturers

Whether they make the tiny clips for sun visors, fuse boxes, water bottle caps or soap dispensers-every single plastic parts manufacturer should be using 3D imaging right now, today. An investment in 3D Scanning equipment or outsourcing 3D inspection to a metrology inspection firm will save them millions of dollars.

CCLicense. Some Rights Reserved. Photo by Kreg Steppe. https://flic.kr/p/5ikjgf

“It’s the other side of beam me up, Scotty!”

3D Printing and 3D Scanning are two sides of the same coin.

Just like 3D Printing and Additive Manufacturing take a computerized model of an item and then turn it into a physical object, 3D Scanning takes a physical object or item and turns it into a computerized model.

The technology today is such that you could take the device you are reading this on right now “beam it up” to the cloud and download it on the other side of the world and print it out. It’s like Version 1.0 of “beam me up, Scotty!”

Today’s 3D Scanning Technology Gives Full Object “DNA”

You can take even the most mundane object and understand more about it than you ever could before. As you look through these images, think about how this capability can apply to your own applications.

Ask yourself:

How could this level of measurement help you create better medical devices?

How could you advance turbine blade manufacture and efficiency?

How could you increase the structural integrity of plastic parts?

How could you reverse engineer competing products to make yours better?

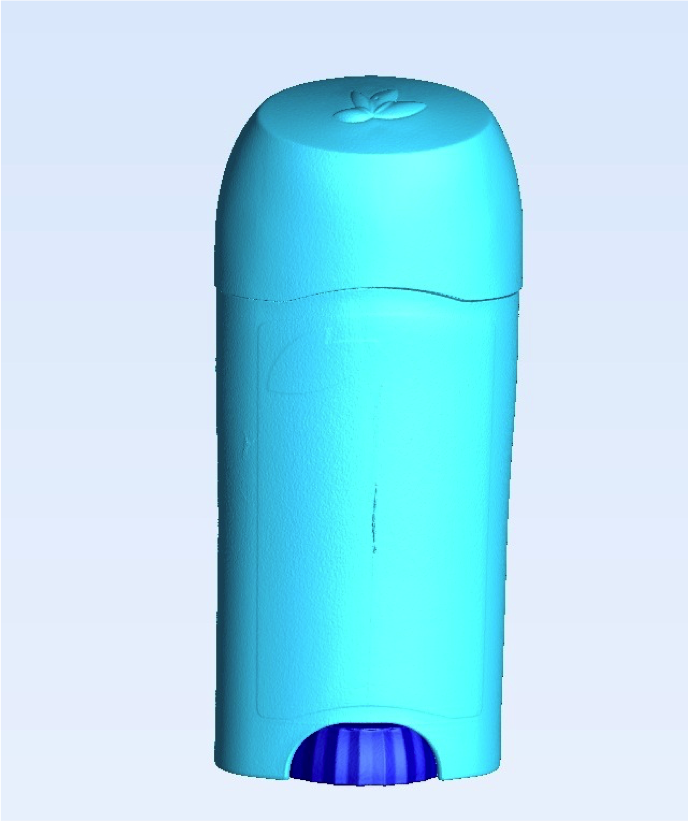

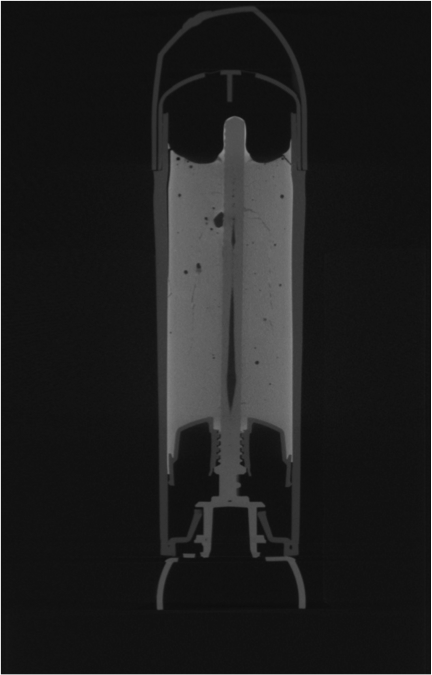

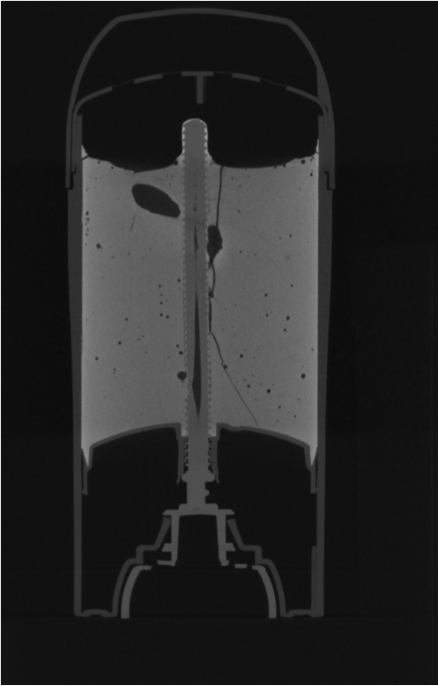

CT Scan of Ordinary deodorant stick from your local CVS.

Scan done on Wenzel exaCT S workstation.

This scan shows the different material densities from a single scan. You get complete “DNA” of the product and its packaging.

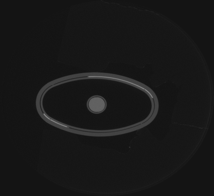

You can also subtract the outer packaging leaving only a picture showing the multi-density of the gel and the central screw mechanism.

What is interesting is how much more this image tells you about your product than any other measuring method in use today.

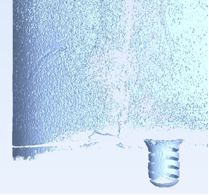

Using the same scan you can pull out all of the packaging and show just where the gel hardens onto the “screw” and makes it difficult for the lifter mechanism to push the material upward or where it can clog the threads.

You can also get 2D “slices” from the same scan. The CT scan gives a full view of the entire finished product inside and out.

An incredibly detailed examination of every bit of the product and packaging from every angle with full separation of all discrete components of each.

What’s the Business Use for CT Scanning of Underarm Deodorant?

This might be a simple and mundane example, but it illustrates the widespread potential in plastics manufacturing, or factually, any manufacturing process.

The above images, from just one scan could help improve packaging that resulted in fewer returns from a “faulty” delivery method – potentially saving the plastic manufacturer’s customers millions in product returns.

Or the deodorant manufacturer could re-work its formulation for less hardening or leakage into the mechanism – also potentially saving millions.

All by itself, this one scan of an everyday product makes a real world use case for massive adoption of 3D imaging in just the single industry of plastic packaging manufacture. But can’t this be translated for use into just about any industrial manufacturing process?

What if you could take apart a competitor’s product & never open the shrink wrap?

CT Scanning Just Might Be The Ultimate Reverse Engineering Solution

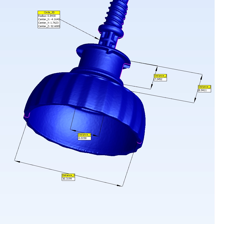

Each and every component is also available in STL format to be used for CAD comparison measurement by virtual CMM or reverse engineering.

You can get full dimensional analysis and measurement of all parts.

You literally get thousands of triangulated data points and all geometries for complete Reverse Engineering of the entire product assembly.

With just a single scan you can inspect every part in the product, with 100s of thousands of data points.

Which you can then take apart and re-engineer with newly designed parts, fixing the problems found in the original packaging and tweaking the design.

Now you can then “re” assemble this newly designed product package…all without ever touching or taking apart the original product or even removing the shrink wrap.

So, tell me again why you aren’t using or at least looking into 3D Scanning technology?

3D Scanning is Revolutionary But We’ve Only Just Scraped the Surface

In future articles in my series on the Fundamentals of3D Scanning and Imaging I will cover the capabilities and limitations of each type of 3D Scanning currently in use: 3D Laser Scanning, 3D Optical Scanning, Structured-Light Scanning and 3D CT Scanning.

You’ll also learn what questions to ask before you buy any 3D Scanning technology solution.

I guarantee that knowledge alone could save you $200,000 or more investing in the wrong technology.

If I’ve piqued your interest about what 3D Scanning can mean to your manufacturing and designing processes feel free to contact on the various 3D Scanning solutions available. We also have a select few slots available to do a complimentary part scan if your company wants to see the power of 3D Scanning right now.