Every year the Wenzel sales staff from around the world descend on Wiesthal, Germany for a week of training and product introductions. With 2016 being my first time to the sale conference and I was floored by the new technologies I was introduced too.

Every year the Wenzel sales staff from around the world descend on Wiesthal, Germany for a week of training and product introductions. With 2016 being my first time to the sale conference and I was floored by the new technologies I was introduced too.

What technologies you may ask? Well, it’s top secret, but it will be released at the 31st annual Control Show this May 9-12 in Stuttgart. Wenzel will be in hall 5 at booth 5102 and we hope to see you there! What I can give you now is a review of our current offerings and what they are best used for so you can appreciate the changes when they come.

LH Generation CMM

The LH CMM is Wenzel’s flagship CMM hand builtd in Germany. It has high accuracy, smooth drives and thick granite. This system is perfect for scanning or measuring precision parts large or small. The LH has the widest range of sizes from a shop floor 5.6.4 to a very large 15.60.12. It also has the most options when it comes to probing. An SP80 or PH10M with an SP25 are great options although but the REVO is its specialty.

CORE

CORE is an optical CMM system with 5 or 6 axes that is typically 5 times faster than a tactile measuring machine. The CORE is ideal for turbine blade inspection, medical implant measurement, or any other parts with polished surfaces and sharp edges. This machine is shop-hardened and has a small footprint.

The CORE machine can measure blades and other parts from 1” to 80” tall and, unlike other non-contact systems, it can be calibrated to ISO 10360 just like a CMM. The CORE uses a high intensity spot of light to measure parts instead of a traditional tactile probe. It is very fast, accurate, repeatable, and reliable.

XO CMM

The XO CMM gives customers a lower cost option to the LH CMM that features the accuracy and quality that customers have come to expect from Wenzel. These CMM’s have granite bearing ways and work best with a PH20 or PH10. Choose an XO to measure machined components, stampings or tooling with the precision of a 2.5micron system.

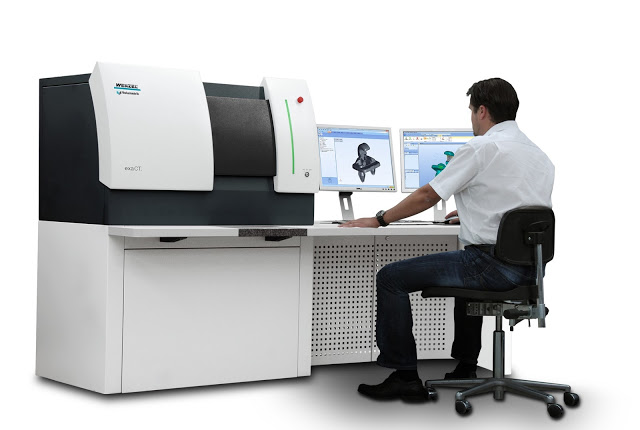

exaCT Computed Tomography System

The exaCT Computed Tomography machine uses x-rays to produce three-dimensional representations of the scanned object both externally and internally. This opens a whole new world of metrology including assemblies, porosity, internal dimensions, and non-destructive testing.

It is important to note that the exaCT is more than a lab device. It is a metrology grade device manufactured by a metrology company. This means the software is easy to use, provides powerful dimensioning tools, and correlates with your CMM. Did I mention they fit on a desk?

What do I like?

What I like is simple… Everything! I know it sounds cheesy but I am proud of the equipment I represent and I am excited for the future of our product lines. Do you make basic parts or are you on a budget? Then choose (or “go for”) an XO. If you make defense/aerospace parts, a LH is perfect. If your turbine blades and blisks need quick measurements, then the CORE is the solution! Do you want the fastest and most robust CMM in the world? The LH with a 500mm/sec scanning REVO head is the answer. No matter what your measurement task, chances are we have a solution. You just need to ask.

If you would like more information regarding Wenzel, please call 248-295-4300 and ask for a sales person. You will be directed to your personal representative.

Scott Romain

Regional Sales Manager Midwest