Growing up, I always wished to have super powers like I saw in the movies. However, I spent more time trying to pick one then I did thinking about what I’d actually do with it. Time travel, invisibility, teleportation, flying, telepathy; how could I pick just one? Well it wasn’t until recent that I realized I get to work with a super power every day and that’s X-ray vision!

Growing up, I always wished to have super powers like I saw in the movies. However, I spent more time trying to pick one then I did thinking about what I’d actually do with it. Time travel, invisibility, teleportation, flying, telepathy; how could I pick just one? Well it wasn’t until recent that I realized I get to work with a super power every day and that’s X-ray vision!

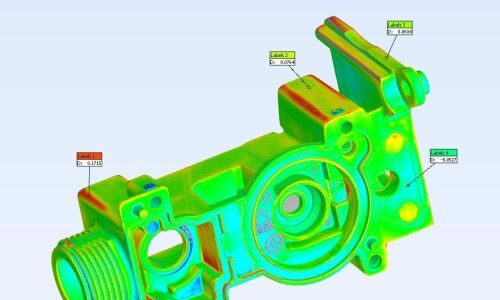

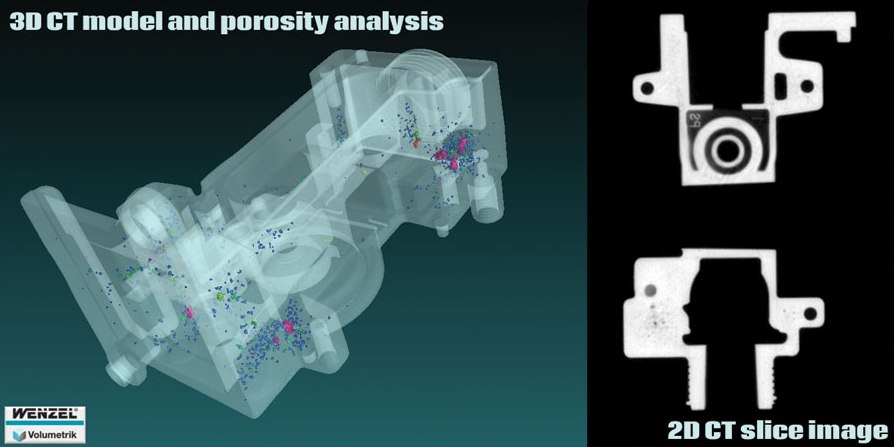

Superman has nothing on this x-ray vision though. While he could see through objects, our CT scanners up the ante, and can generate a 3D volume from the individual 2D x-ray projections that are taken during the scanning process. This 3D volume is what makes CT scanners such a powerful tool. With the 3D volume, you can create an STL file for 3D comparisons to CAD or use it for another form of inspection called NDT.

With NDT or non-destructive testing, we are able to scan entire assembled parts that have intricate inner workings and see exactly what is happening inside them. This gives manufactures the ability to pin-point defects in assemblies without opening them up and potentially destroying the cause of the defect or the part itself. Once we have a part scanned, we can section through the scan volume in 2D or 3D to find defects or to see how individual parts are mating together inside. No more having to guess what’s wrong inside your part.

NDT is especially useful for inspecting circuit boards, electrical connectors and assemblies, key fobs, valves, perfume bottles, motors, etc. Over the years as a CT Technician, I have seen my fair share of unique parts that have benefited from CT scanning and NDT. Our customers are always amazed at what they take away from our online sessions where we are able to review the scan data and work on finding the cause of their problems together.