Regular readers of our blog will remember the incident when the primary drive belt failed on my restored 1972 Triumph Trident motorcycle, and I used some CT scans to diagnose the issue. That was on one of the hottest days of the year in Michigan which might have been something to do with it.

Those days seem impossibly long ago now that the temperatures are below freezing every day. I’m hunkered down in the house evenings and weekends and like other bikers and summer sports enthusiasts looking to find interesting things to do to related to our favorite pastime.

Those days seem impossibly long ago now that the temperatures are below freezing every day. I’m hunkered down in the house evenings and weekends and like other bikers and summer sports enthusiasts looking to find interesting things to do to related to our favorite pastime.

One thing I thought about was whether there was anything I could do to solve technical issues on my bike that might take time and not require me to be outdoors. One issue that had been a problem all season was ignition coils. Now to anyone familiar with old British vehicles; this is hardly a surprise but what might be surprising to them is that the problems I have had are not with the 40-year-old Lucas coils, all of which work well but with some modern supposedly high-performance copies bought new.

As a result of experiencing problems with two out of the now five new coils I’ve bought for the bike, I was able to select one sample coil that had given no problems and a second that had suffered from intermittent sparking resulting in a misfire on one cylinder. The Trident has three cylinders and one coil for each cylinder. Like the majority of electrical problems, the difficulty with identifying a root cause is when the problem is intermittent.

As a result of experiencing problems with two out of the now five new coils I’ve bought for the bike, I was able to select one sample coil that had given no problems and a second that had suffered from intermittent sparking resulting in a misfire on one cylinder. The Trident has three cylinders and one coil for each cylinder. Like the majority of electrical problems, the difficulty with identifying a root cause is when the problem is intermittent.

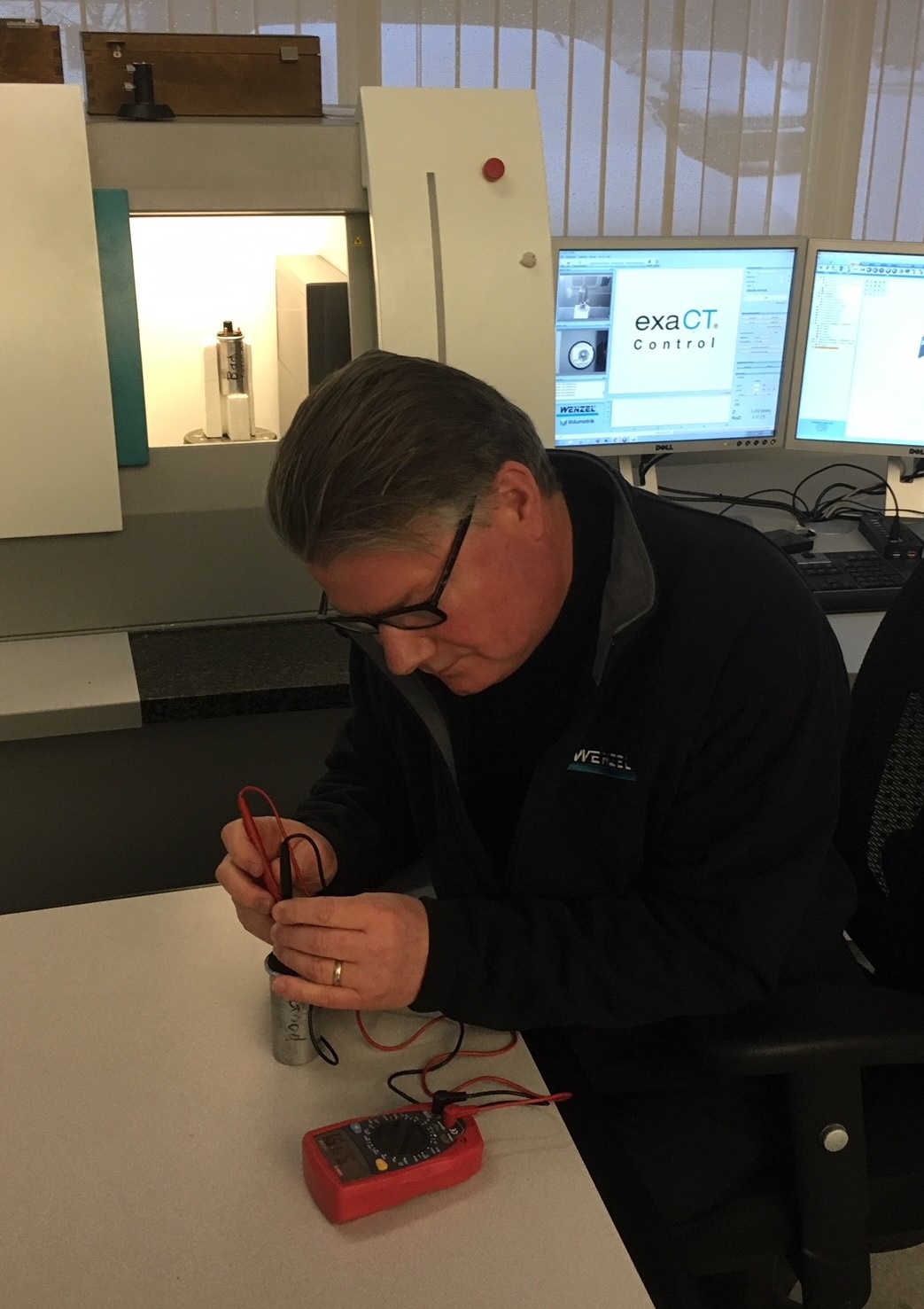

The usual testing method with a multi-meter is of limited use because the problem is intermittent and usually doesn’t show up when the part is tested; only when in use. So how do I identify which are the good coils from the bad?

The usual testing method with a multi-meter is of limited use because the problem is intermittent and usually doesn’t show up when the part is tested; only when in use. So how do I identify which are the good coils from the bad?

Fortunately, in my role as Manager of the CT department at Wenzel America I have access to just the tool for the job!

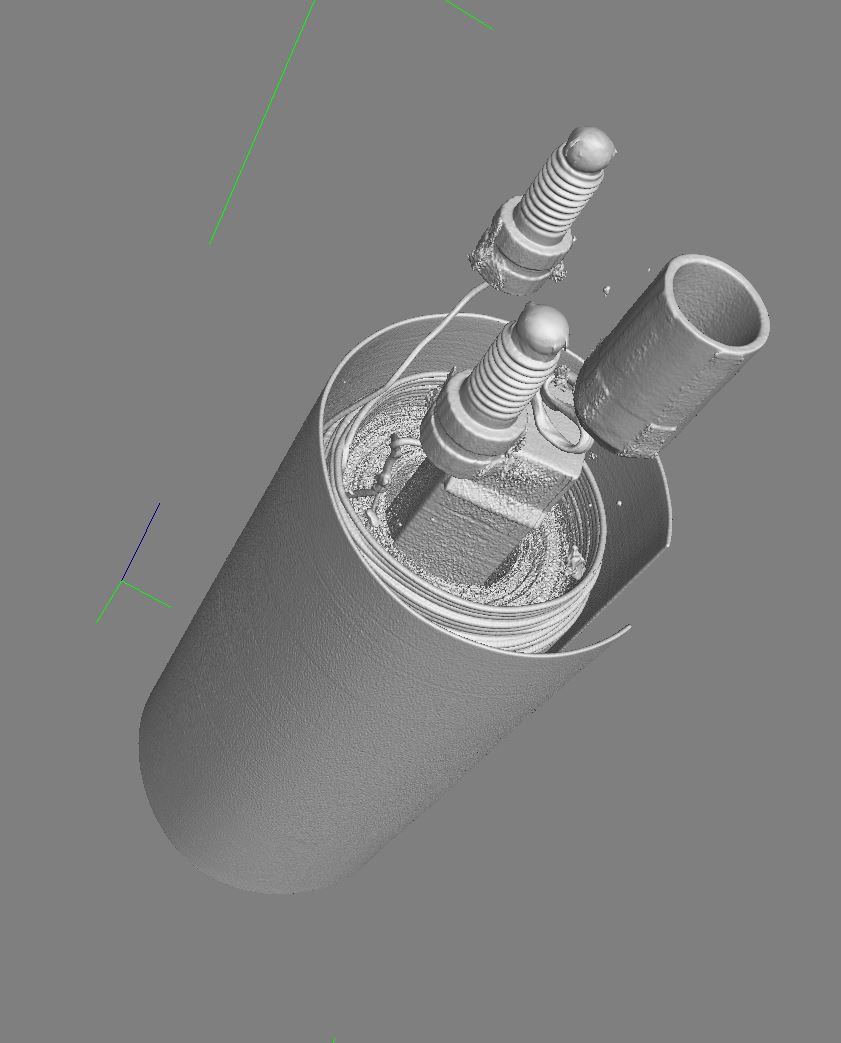

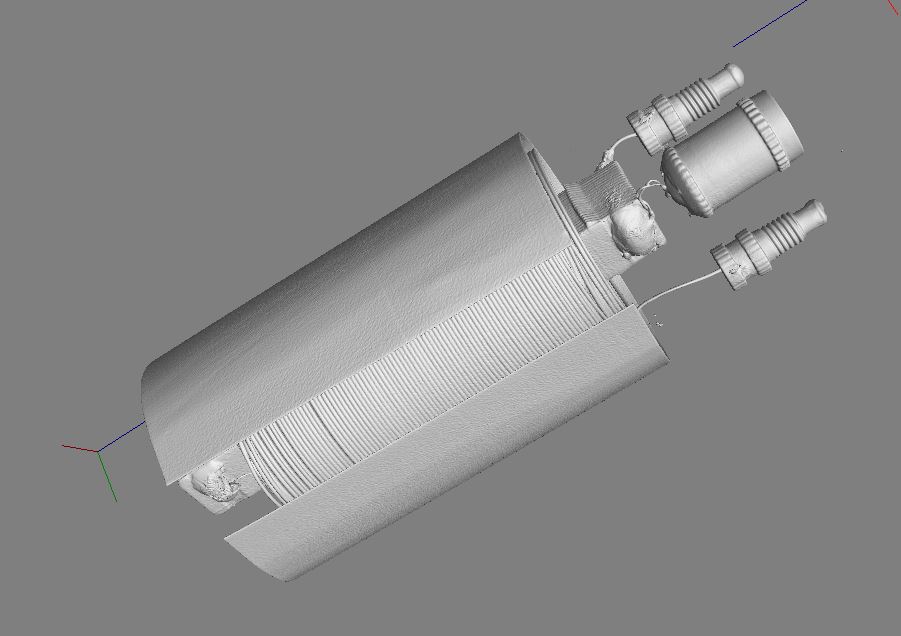

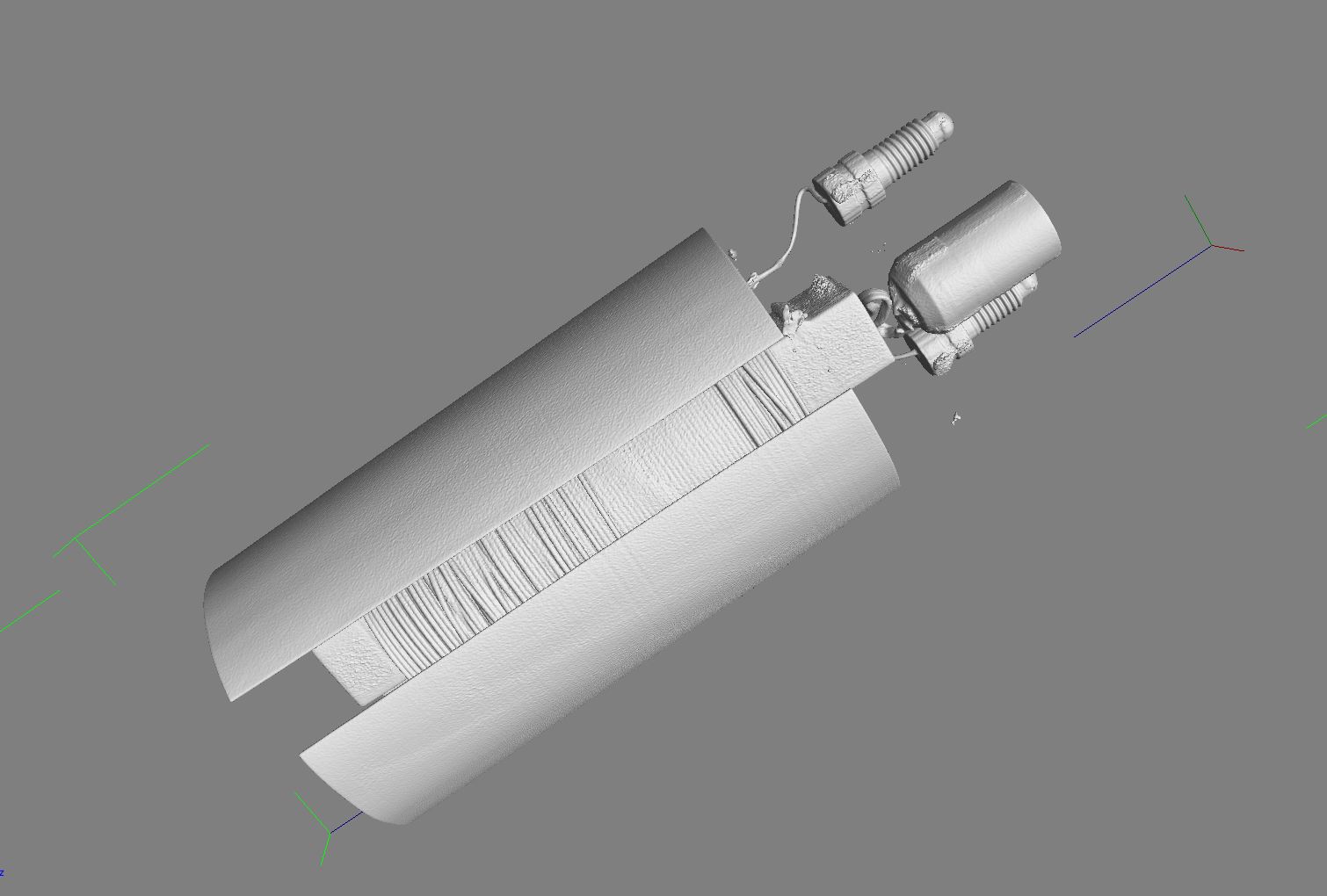

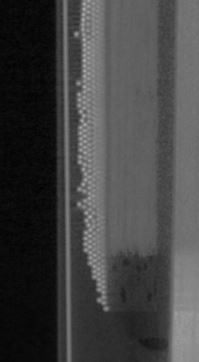

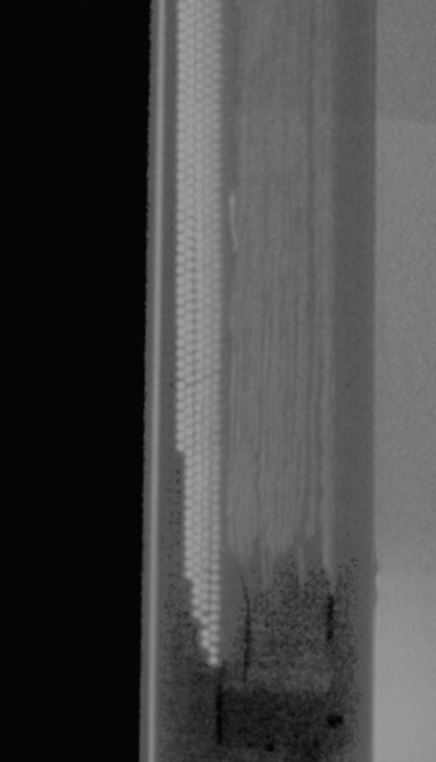

Using the Wenzel exaCT M 200 HE scanner in our Wixom MI facility I was able to CT scan both coils and take a look at what was going on inside.

Because the CT scanner is able to see right inside a closed metal insulated case and identify all the different materials inside, I was able to inspect the insides of the coils in great detail. As you can see from the pictures it is immediately obvious that the outer primary coil in the “BAD” coil is very loosely bound and whether it was made this way or has become this way in use is clearly defective when compared to the “GOOD” one.

Not surprisingly (since both passed the Multimeter test) close inspection of the individual wires did not reveal any breaks in the circuit. Had there been breaks they would have been easy to spot. Even so, it was definitely possible to see the defects in the one coil and I will not be using it again.

I can’t wait to scan the remaining three coils to see if I need to beware; It’s amazing what passes for entertainment when there’s two feet of snow on the ground and nothing else to do!

That having been said; If anyone else reading this has reliability issues with closed electrical components and would like to get to the bottom of them without destroying the evidence in the process; Give me a call, or email me. I can help.