Regular readers of my blog will be familiar with the way that I like to seek out the most difficult metrology challenges from eyeglass screws and ignition coils to chocolate bars and show how by using CT scanning technology one can measure things that could not be measured any other way.

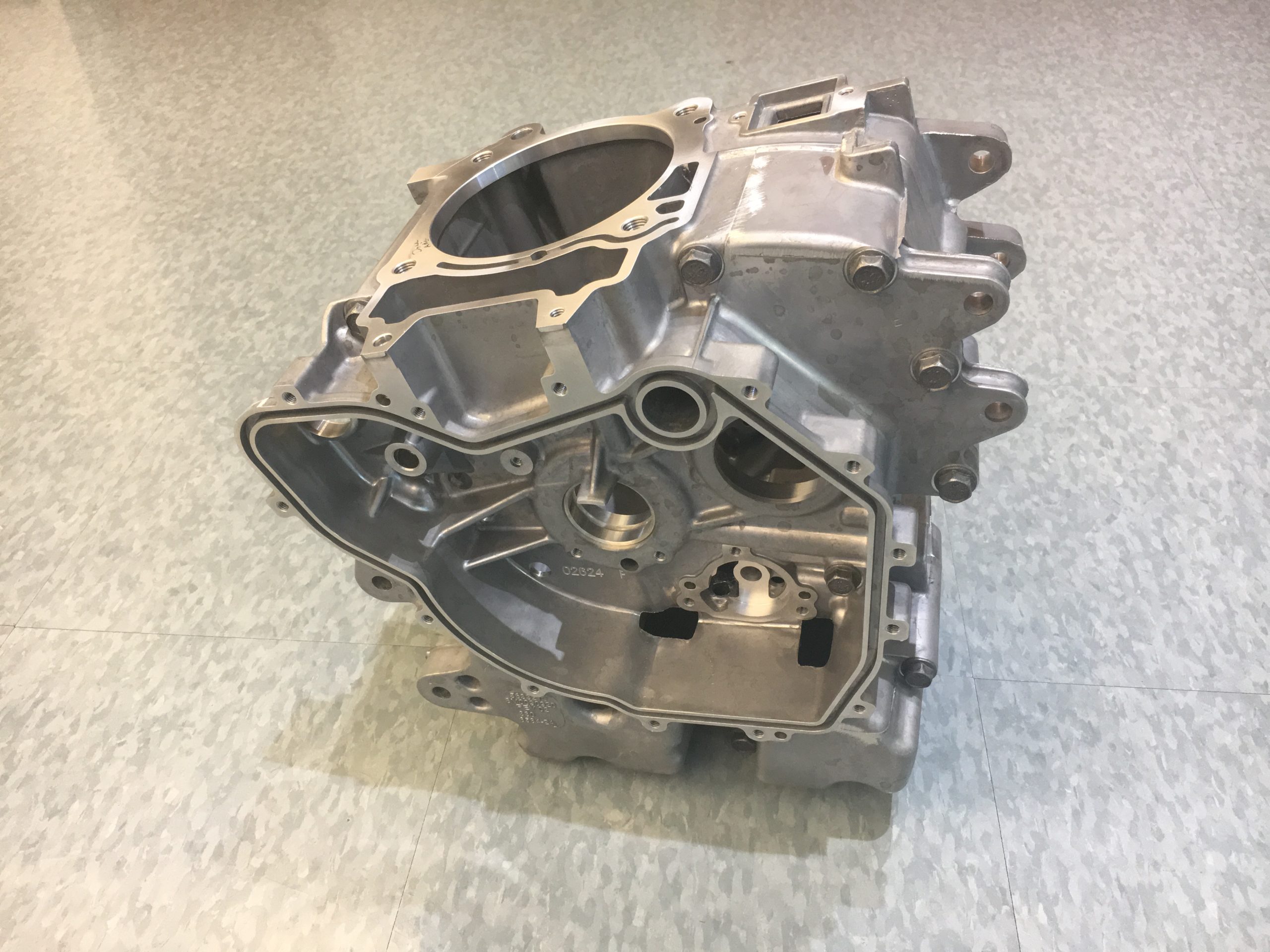

Have any of you wondered whether on the other hand there are things that cannot be scanned by CT? I confess there are such things, typically if parts are too big to be fitted in the machine or are made of metal too thick to be penetrated by X-Rays then they cannot be measured by CT.

In most cases there are alternative measurement techniques that can be used on large parts such as CMMs or laser scanners that will perform well but there are some applications that cannot easily be measured by CT, CMM or Laser scanner. Not surprisingly, in our role as a service provider, the CT Lab at Wenzel America does get to see these applications from time to time.

In most cases there are alternative measurement techniques that can be used on large parts such as CMMs or laser scanners that will perform well but there are some applications that cannot easily be measured by CT, CMM or Laser scanner. Not surprisingly, in our role as a service provider, the CT Lab at Wenzel America does get to see these applications from time to time.

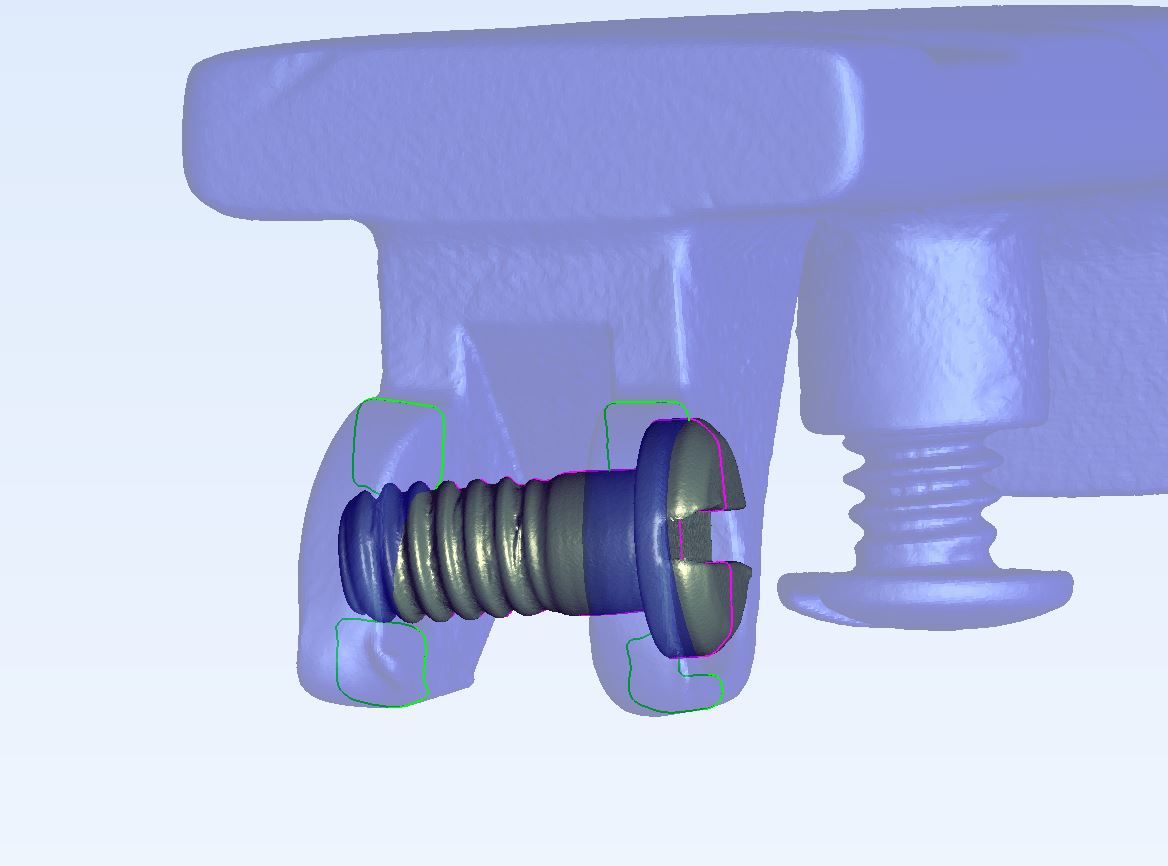

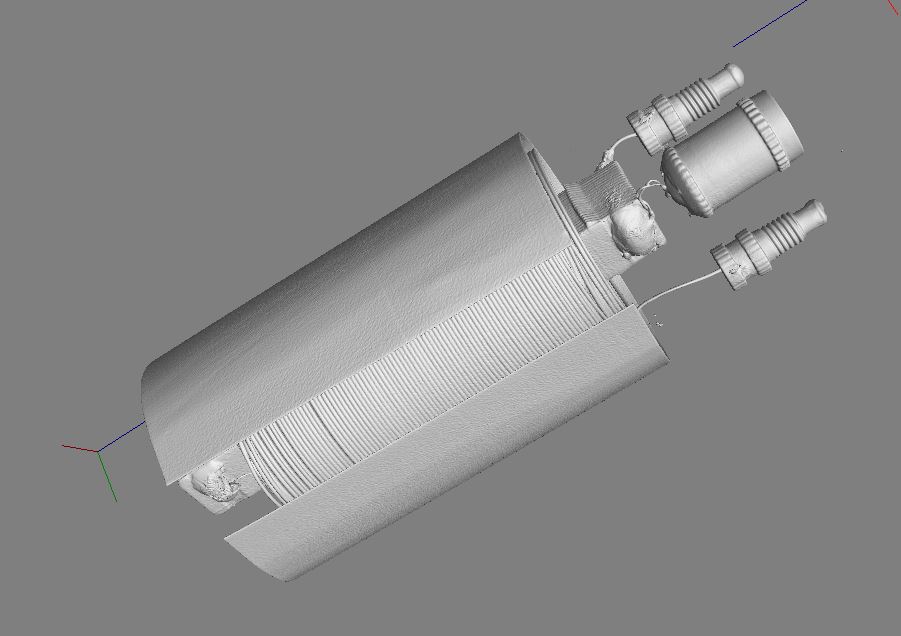

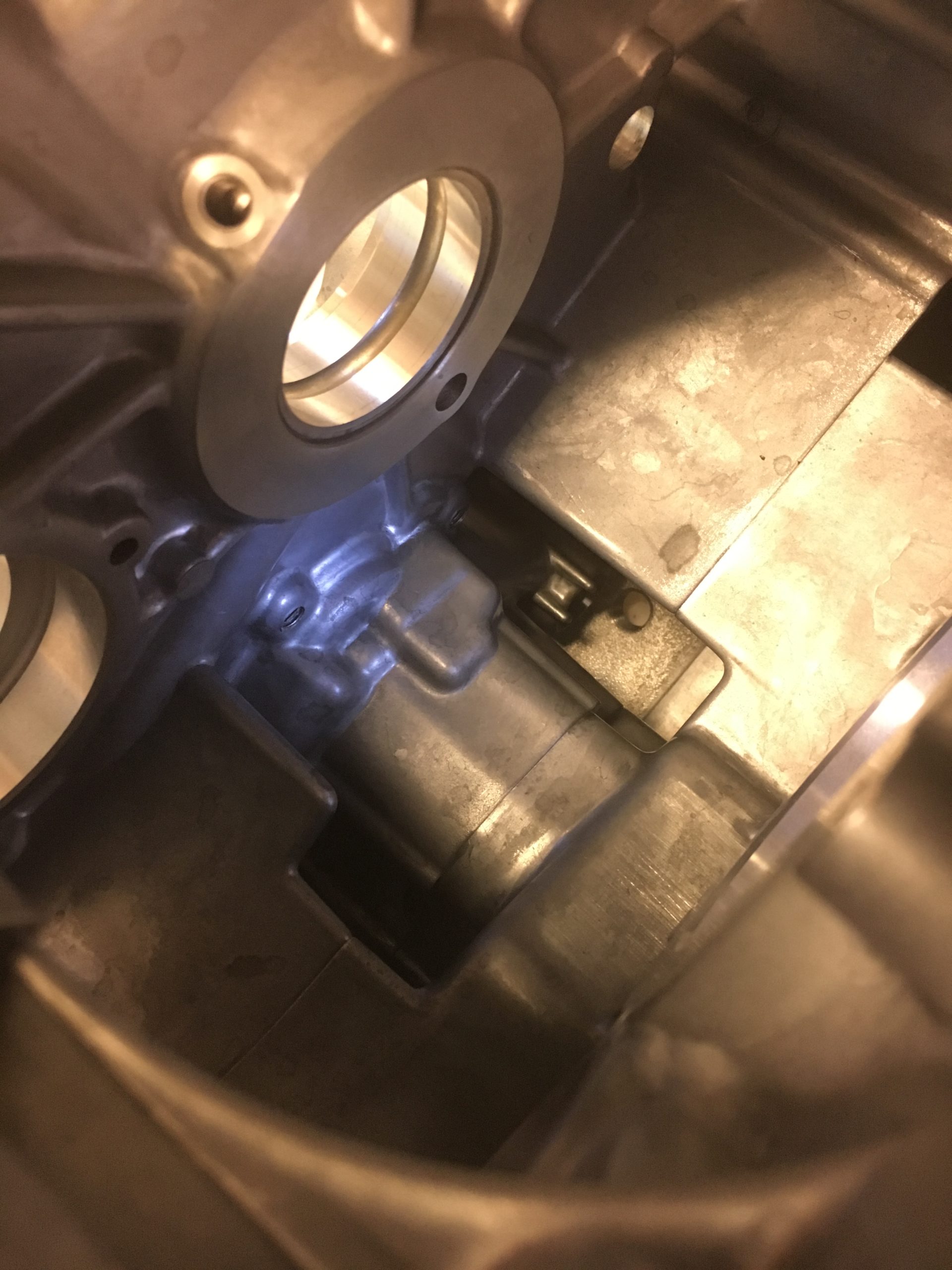

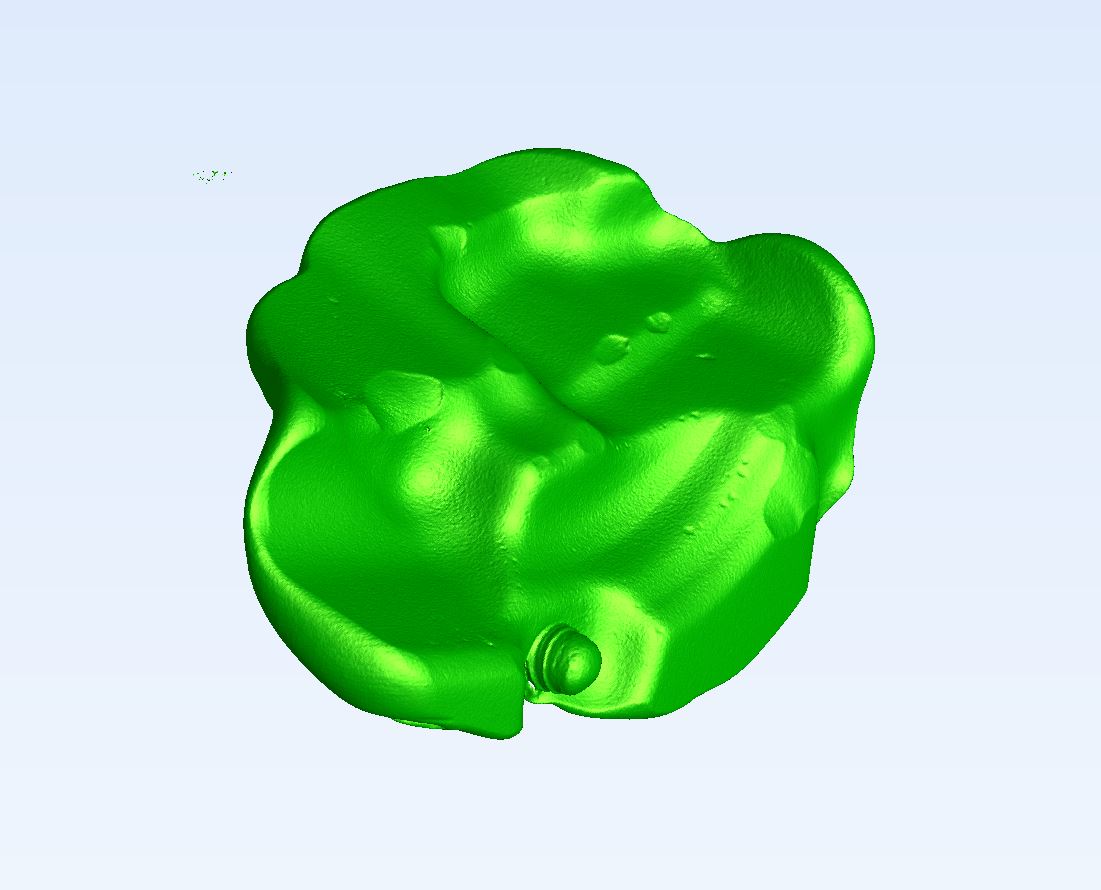

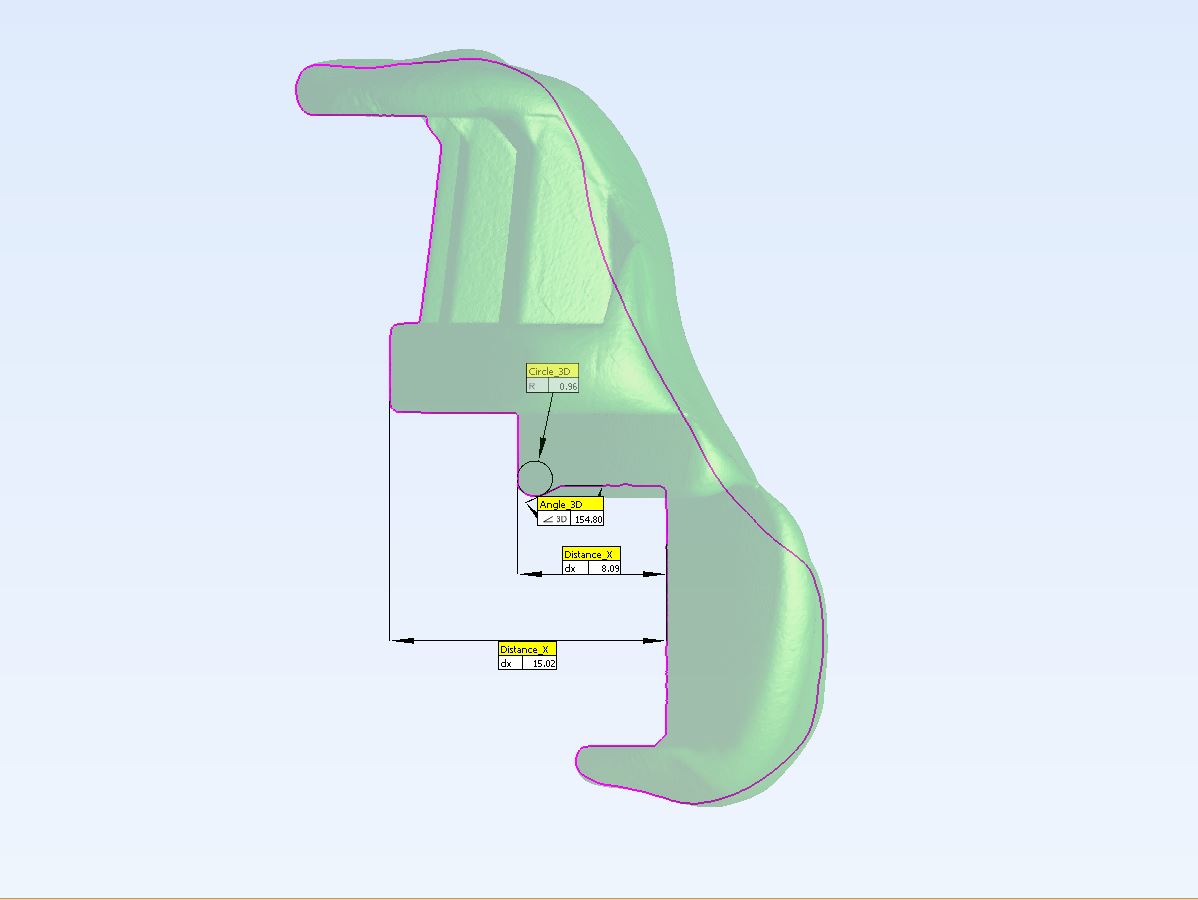

One such application is where there is a need to do Reverse Engineering of a part, such as a casting too big to put in a CT Machine, where the geometry is too complex for a CMM, and inaccessible to a laser. In the pictures you can see how dimensionally stable dental impression material, applied to geometry deep inside a casting, can be removed, CT scanned and the resulting scan measured electronically.

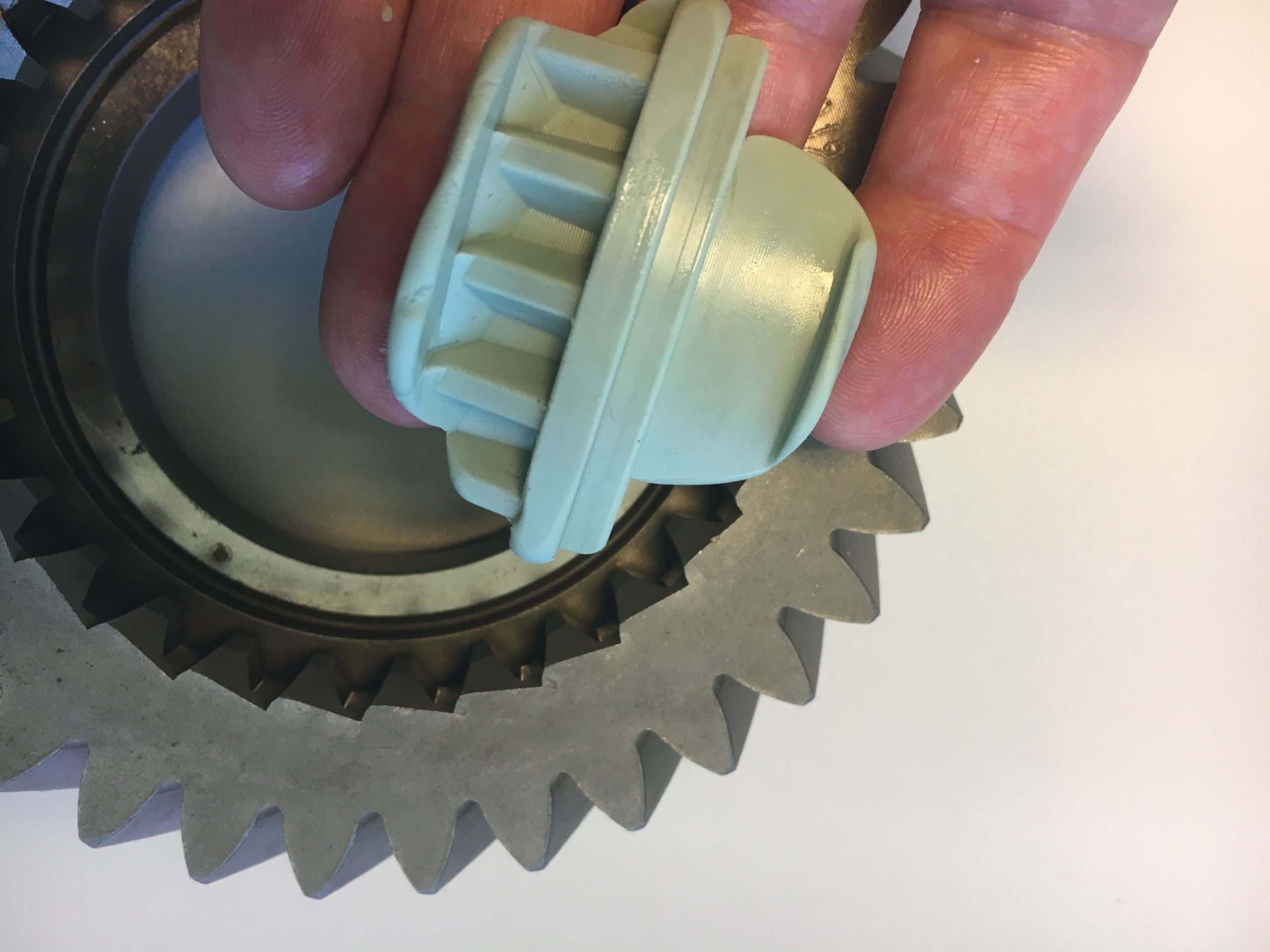

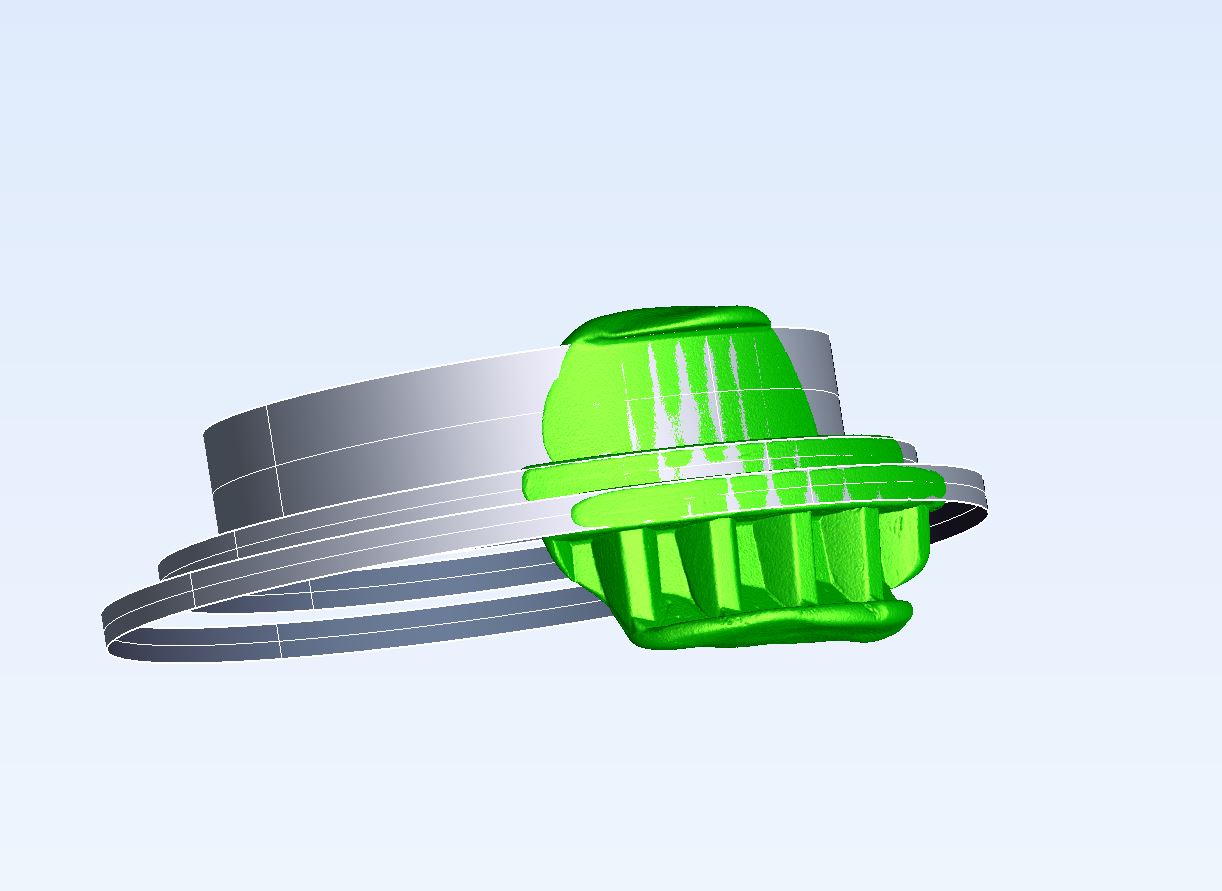

Another example shown here is where complex geometry on a metal gear, too thick to be scanned by CT and with geometry inaccessible to a CMM. Using an approach similar to that on the casting, an impression is made from which accurate geometry can be reverse engineered.

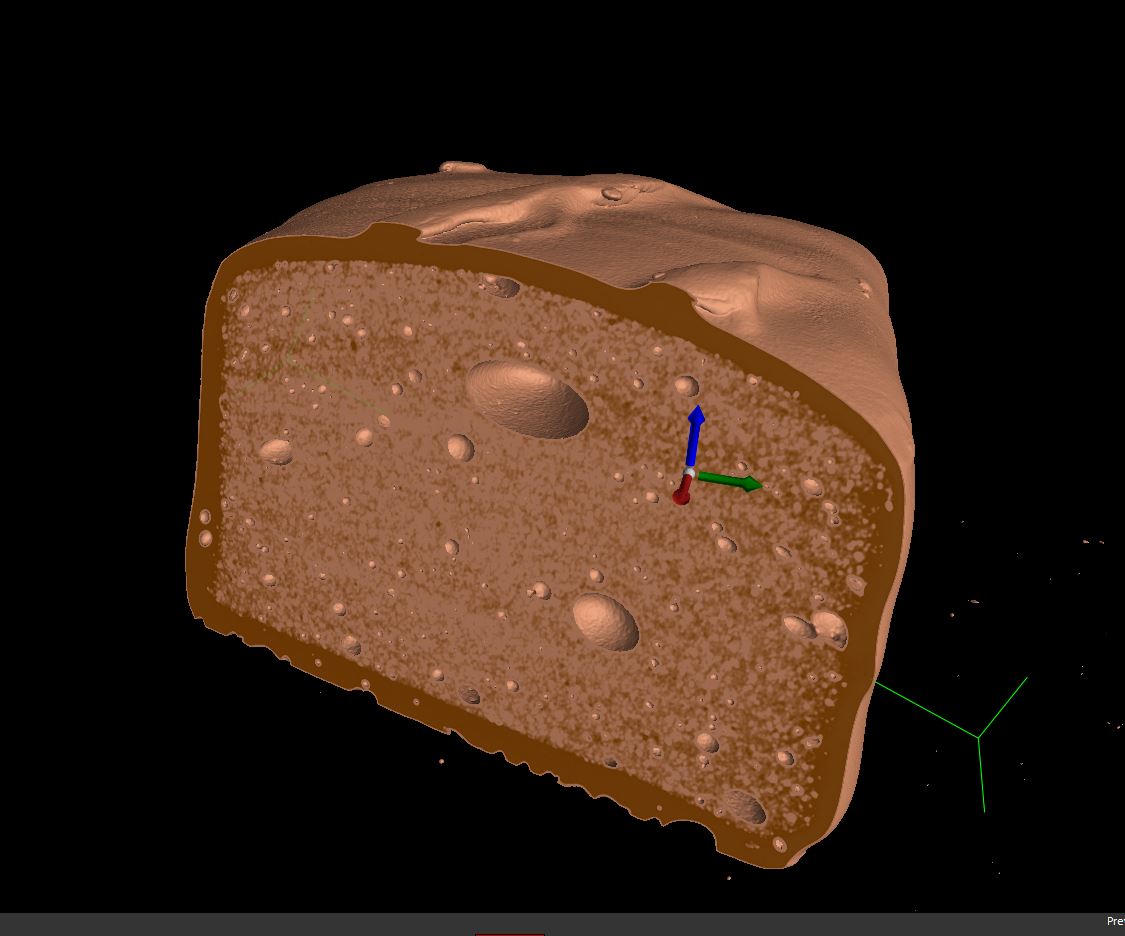

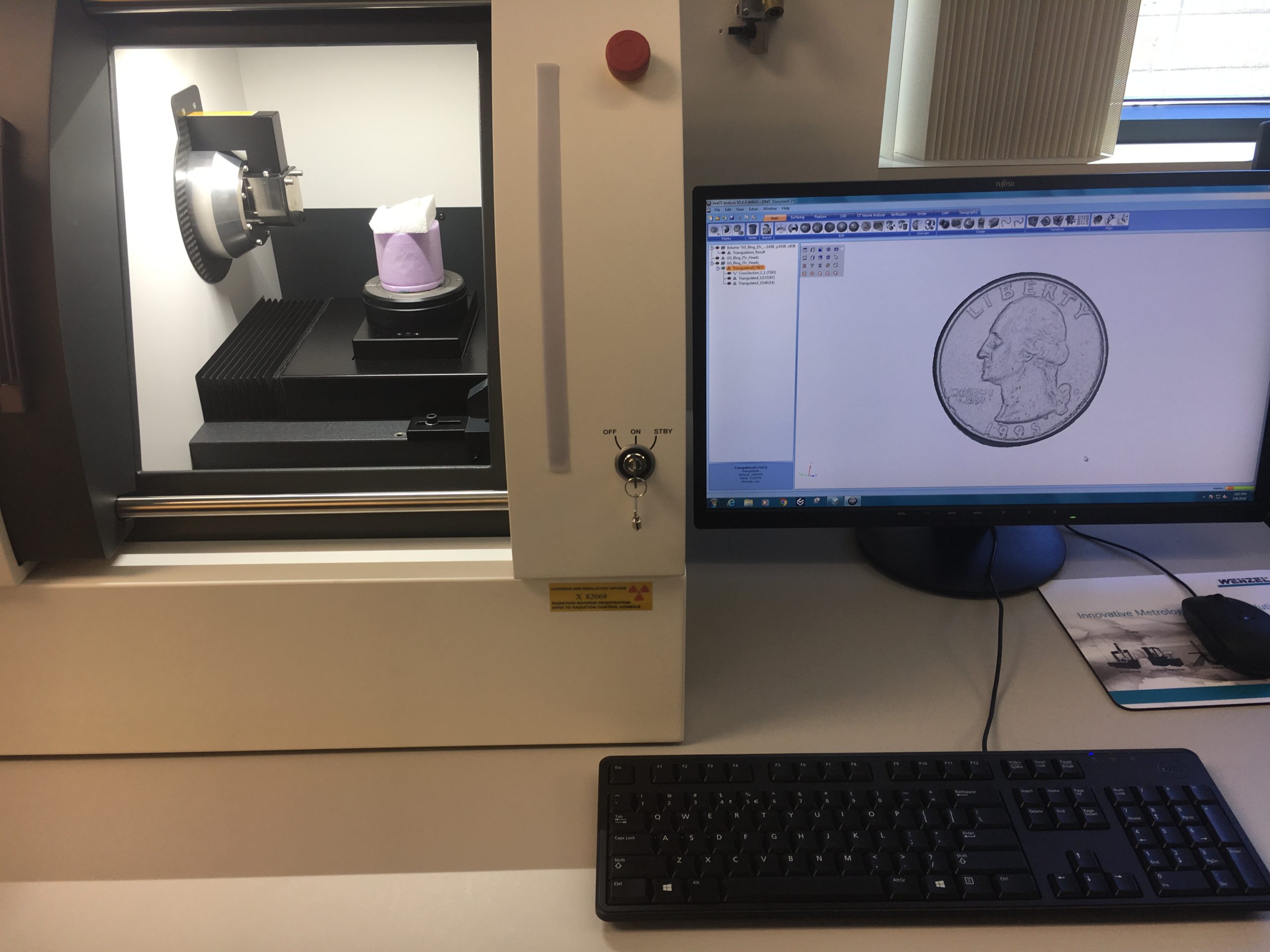

The final example is a scan of a surprisingly difficult part to measure; A coin. The difficulty in getting a good scan of a coin is that in a CT Scanner, there is no way to avoid at some point having to go penetrate the whole diameter of the disc. that means an inch of nickel in the case of a US Quarter. That’s too much metal for a scanner with the delicate high resolution touch required to be able to capture the subtleties of the relief to penetrate. It is worth pointing out too that such fine detail would be lost if the part needed to be painted white in order for a laser scanner to work but once again the impression method works well.

If you find yourself with a measurement task that seems too difficult to be solved by using any know method of measurement even CT, don’t give up, give us a call, we might have a work-around.