My first job out of school was as an Engineering Undergraduate Management Trainee at Cabury’s Chocolate factory in Bournville England. My initial placement was in plant maintenance supporting the packaging department; the environment of which was well described by Lucille Ball in her famous chocolate factory skit.

It was with mixed feelings that I went to work every morning; On the one hand, it was permissible to eat as much chocolate as you wanted which to an 18 year old was an unbelievable treat, but on the other hand being outnumbered about 100 to one by women was a lot less fun than you might think – Workplace harassment of teenage boys was considered more of a sport than a crime back in those days!

In time I moved on to other parts of the company and finally into Research and Development. This was a truly fascinating place where all the secrets of how chocolates and candy are made to taste the way they do are held in great secrecy and reverence. Everyone has their favorite candy and each for different reasons. The exact taste, crunch, snap and creaminess that go to make up the eating experience do not come about by accident but as a result of rigorous experiment, and subsequent quality control. Tiny changes in the mix of ingredients might completely change the taste of a product and might also, since millions of pieces are made, make a big difference to production costs too.

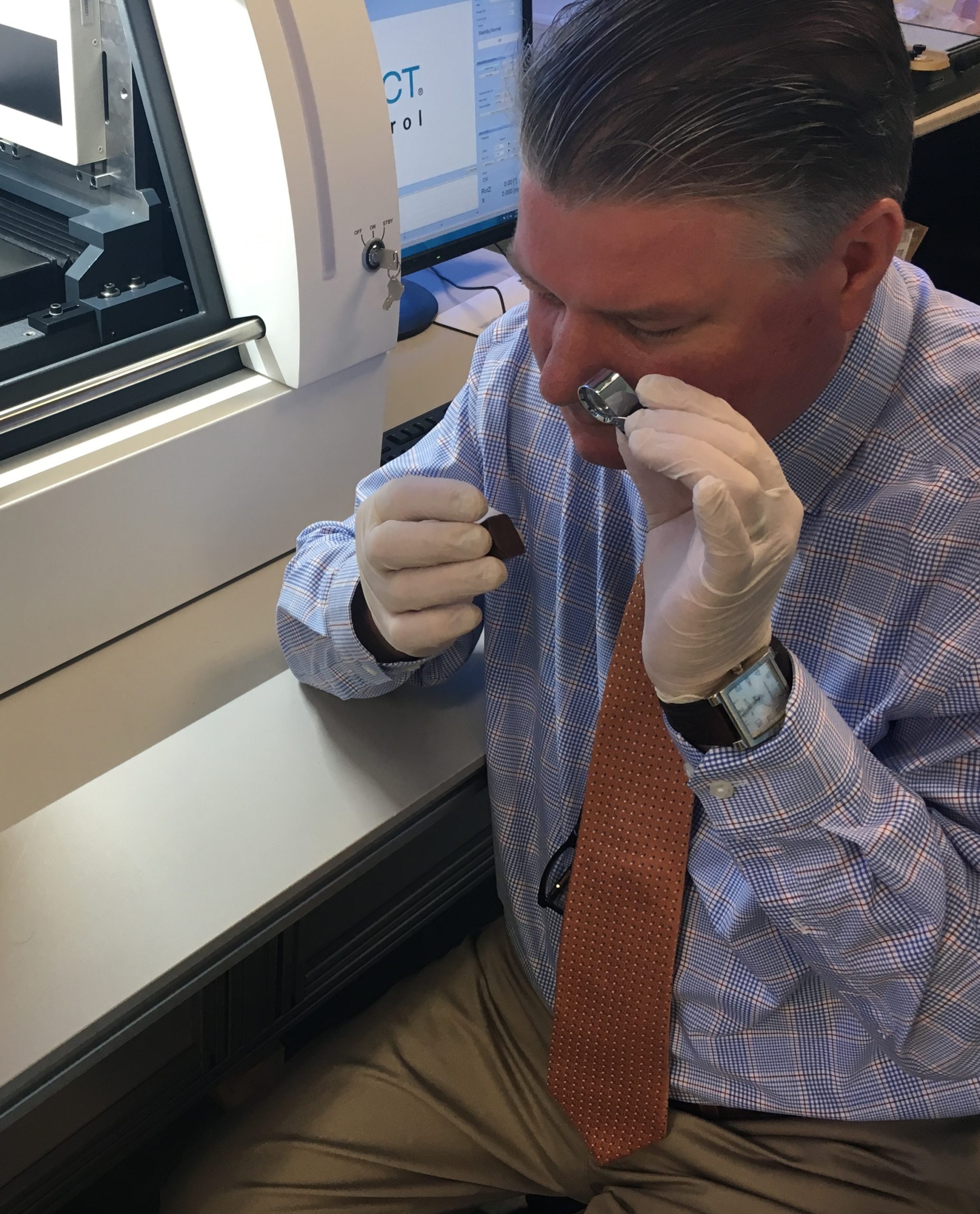

In order to understand how the final product had turned out involved eating some (that was the easy part) then cutting up samples and painstakingly separating out the contents for examination under a microscope or by weighing.

In the same way that the workplace has moved on and the hand packing of chocolates has by now become an automated lights-out operation, so too has the technology of analysis and measurement. Looking back now from my privileged position as Manager of CT Systems and Services at Wenzel America, I can see how useful it would have been to be able to use today’s desktop micro CT technology for the analysis of the finished product without ever having to cut it up.

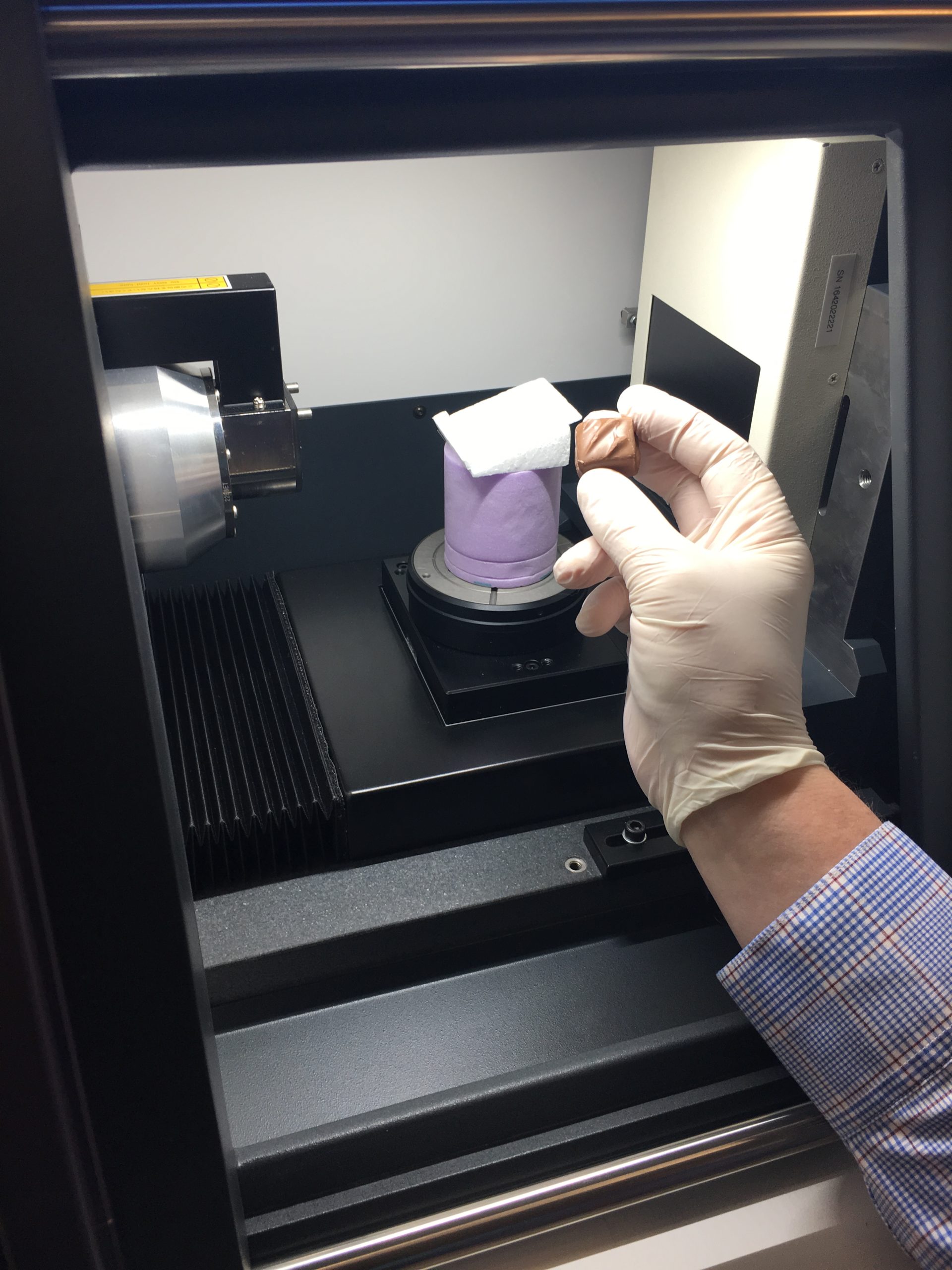

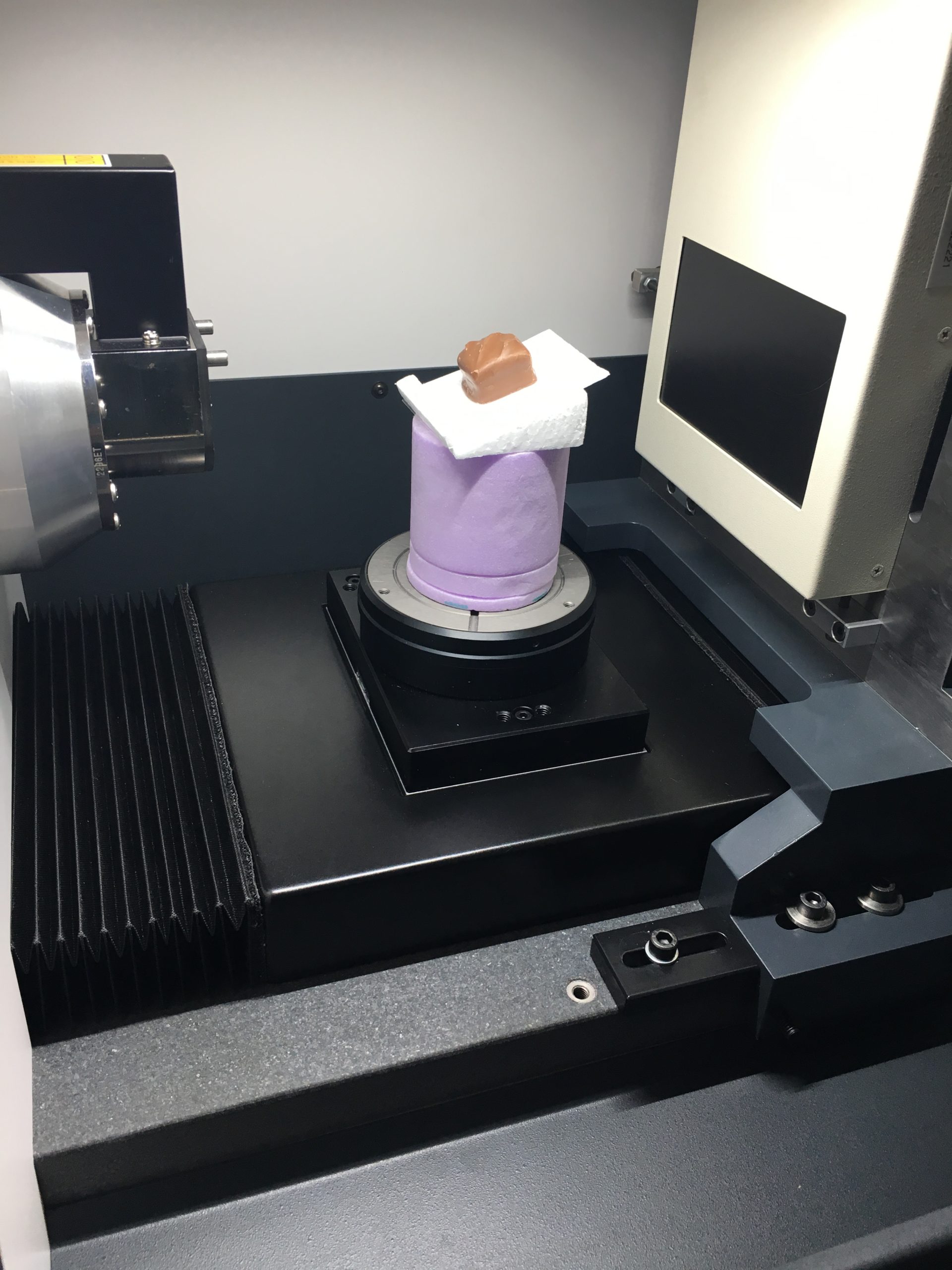

Out of interest, I bought some candy and decided to do some tests of my own to see what could be achieved with todays tools.

I selected some familiar items that had both unique and distinctive contents and gave nothing away on the outside as to what those contents were. I scanned them in the exaCT S90 Desktop scanning machine in our Wixom Michigan lab at a resolution of 20 microns to see what I could find.

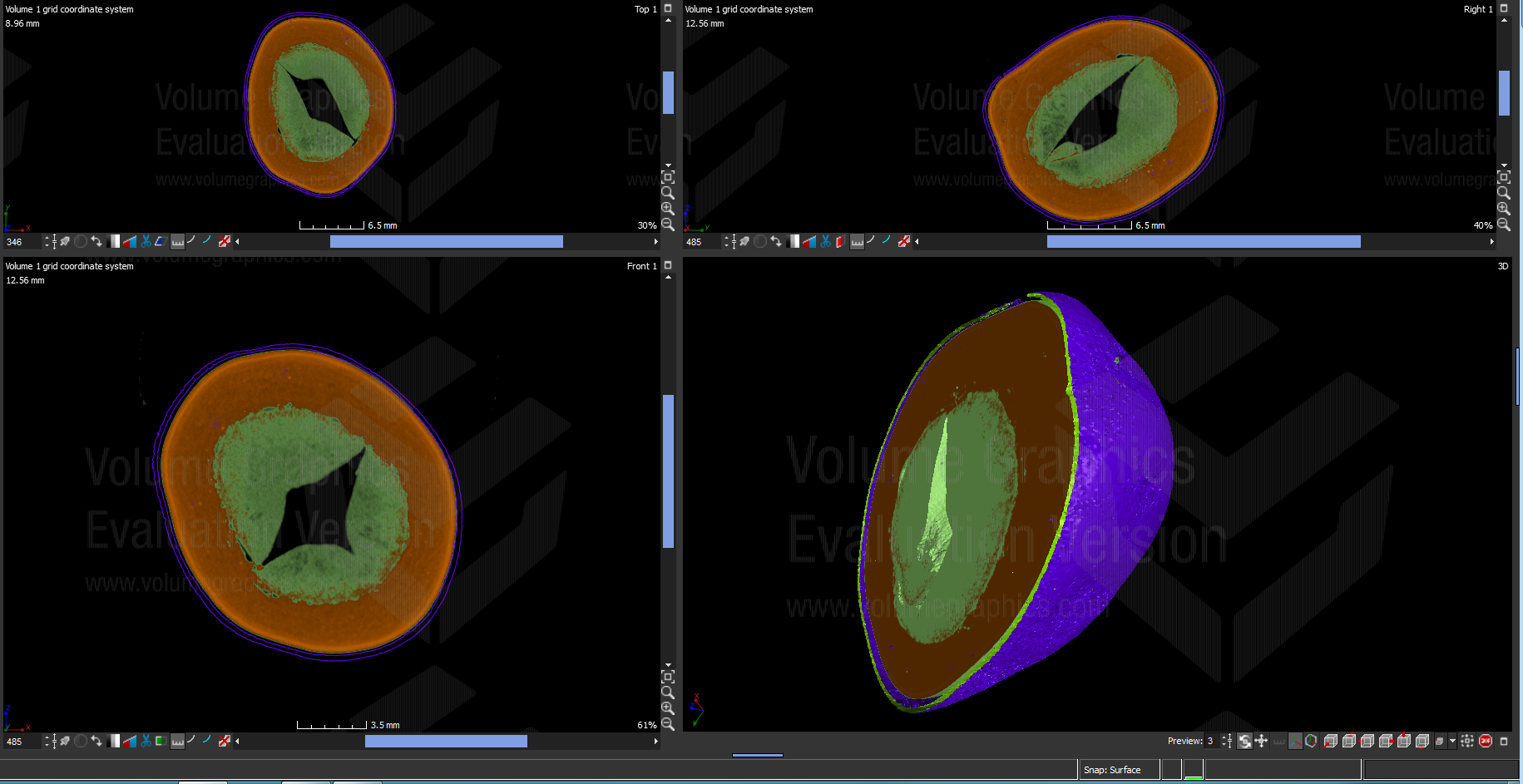

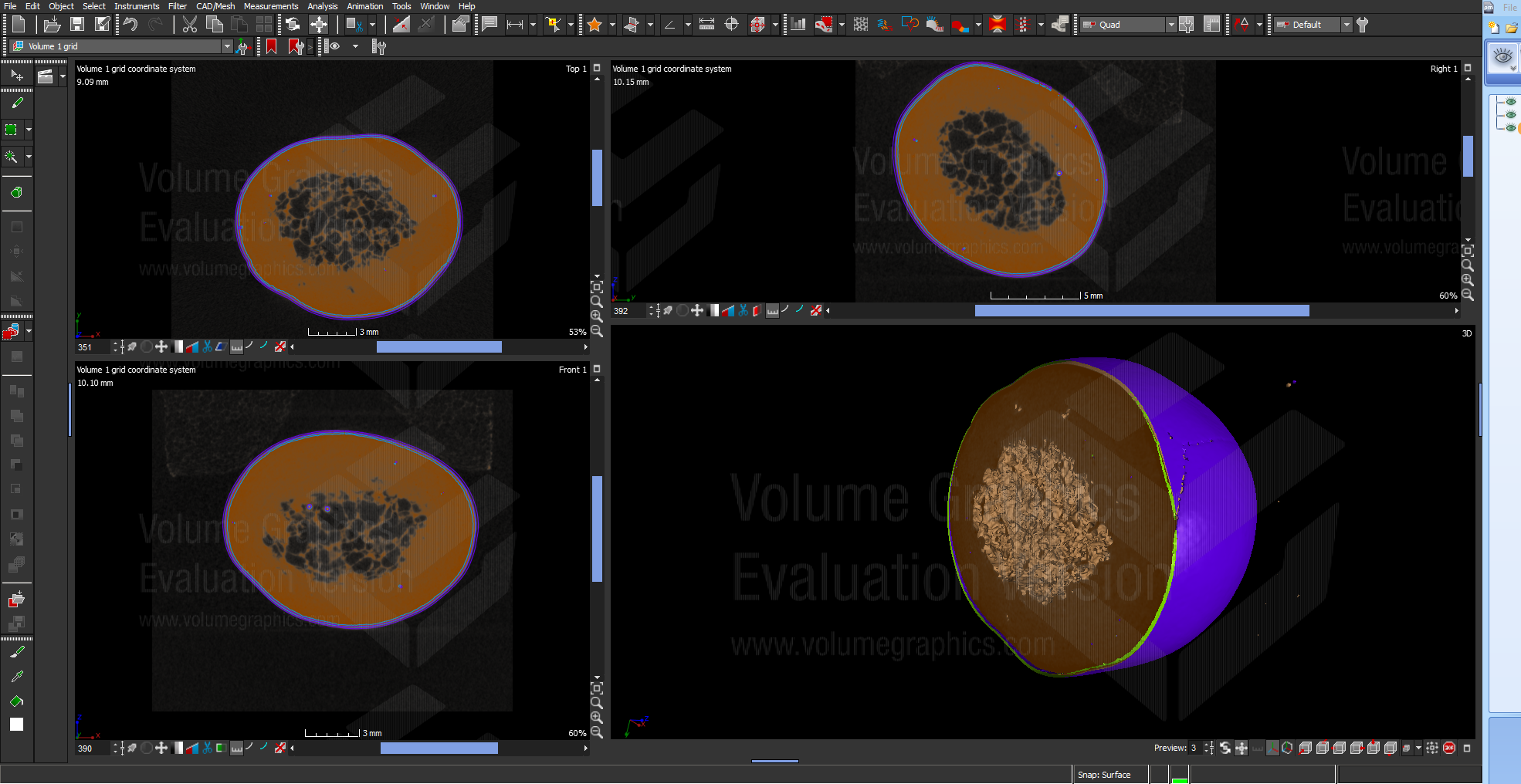

The results were very good and it was immediately obvious to me that what could be achieved with CT technology exceeded even my expectations Take a look at these examples:

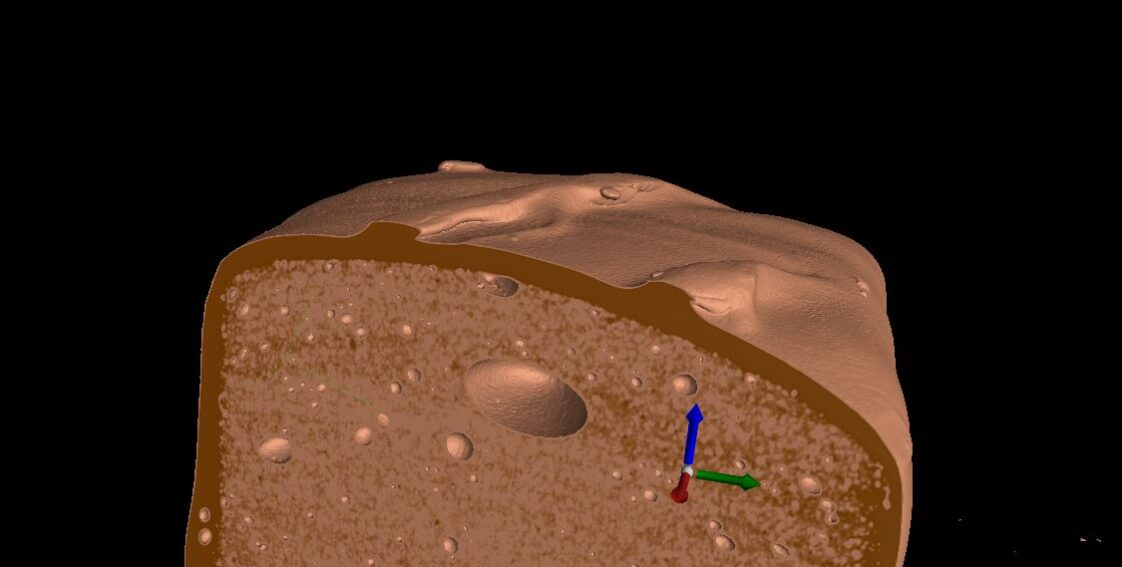

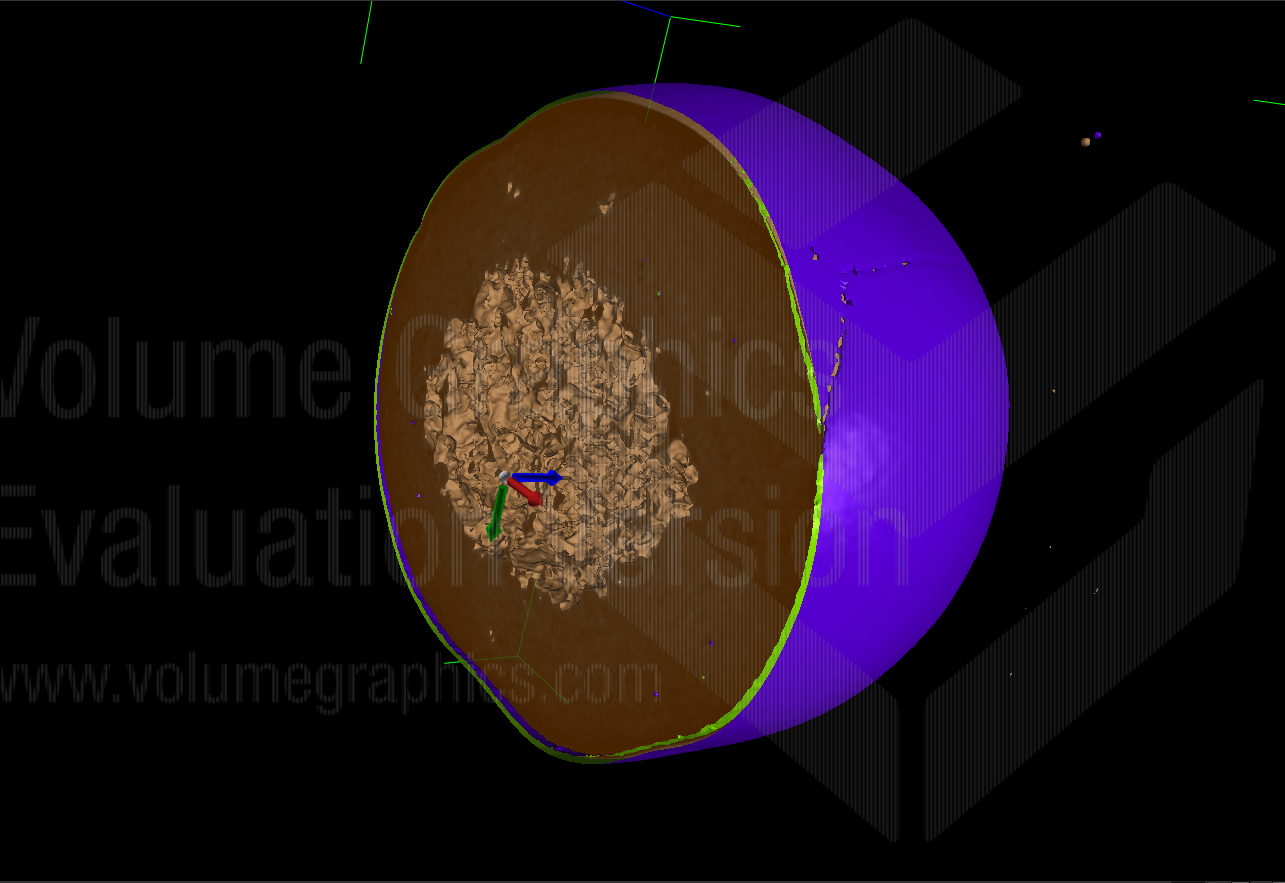

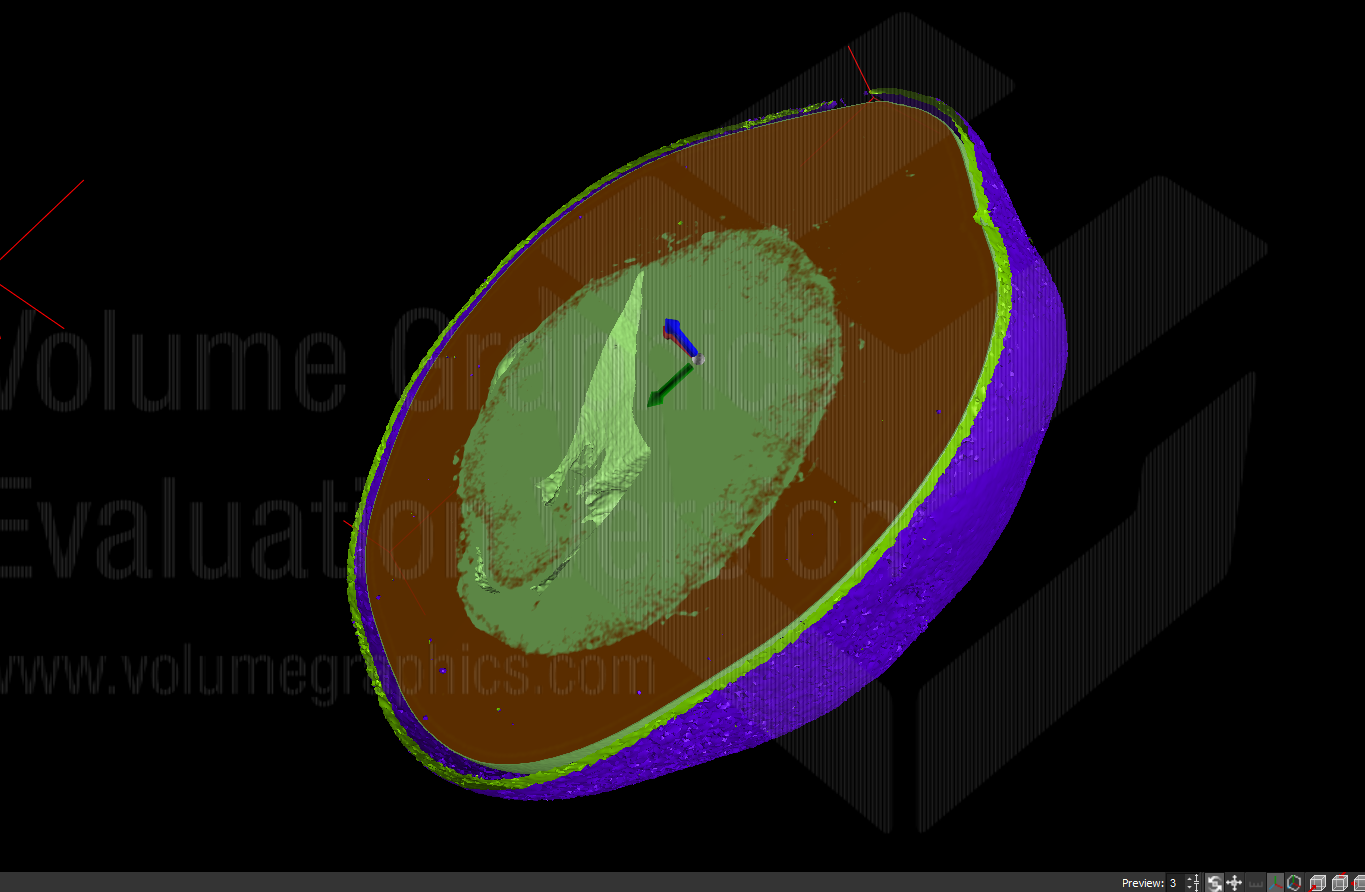

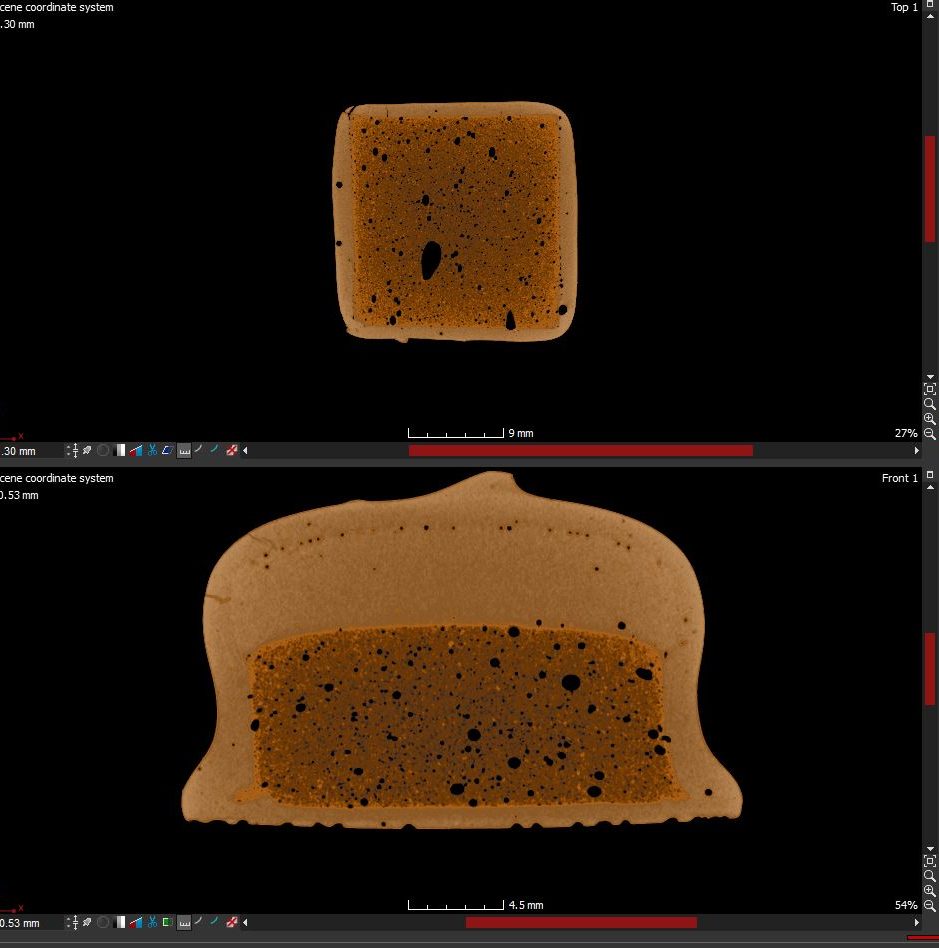

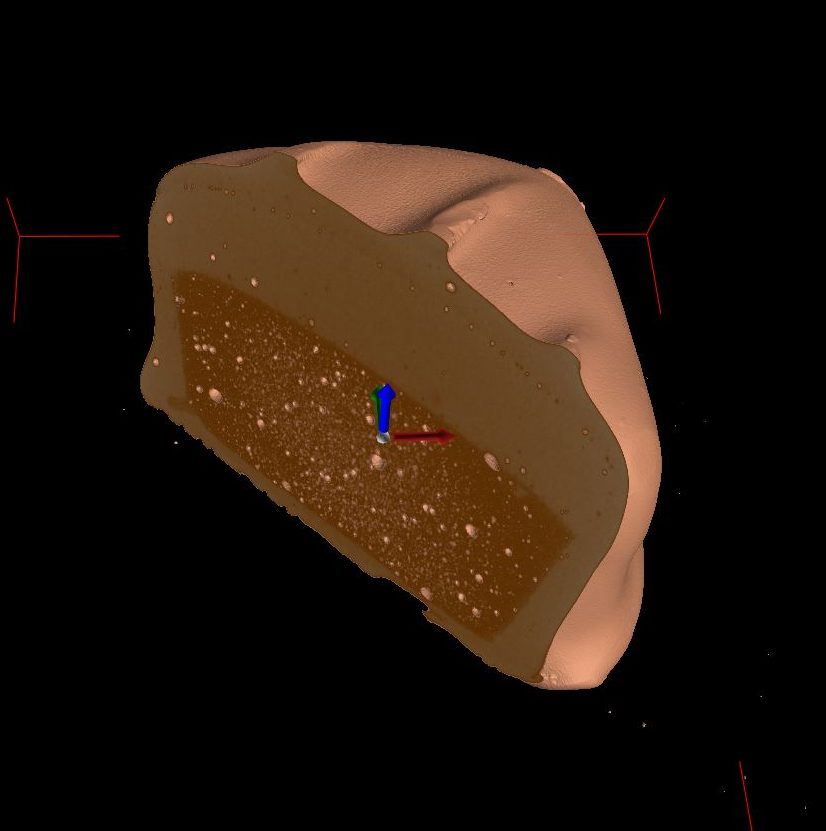

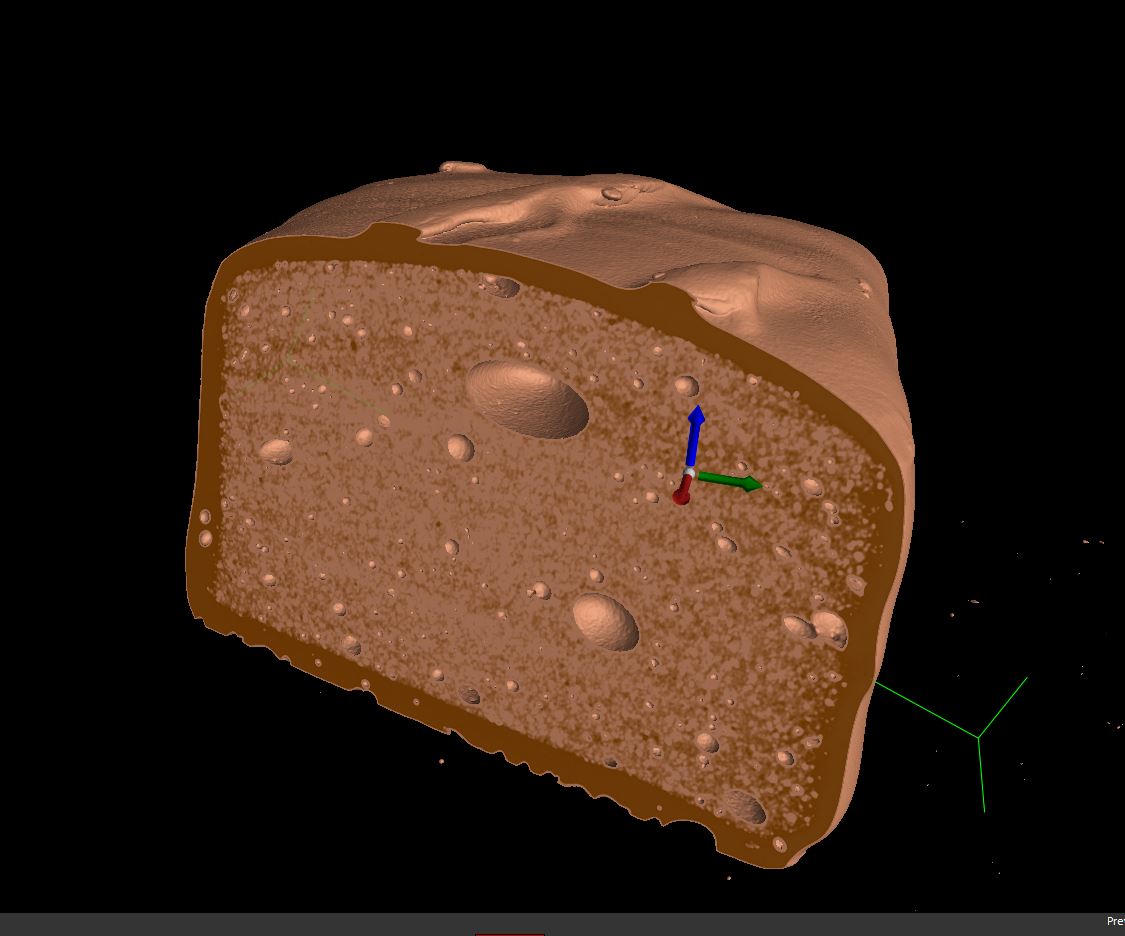

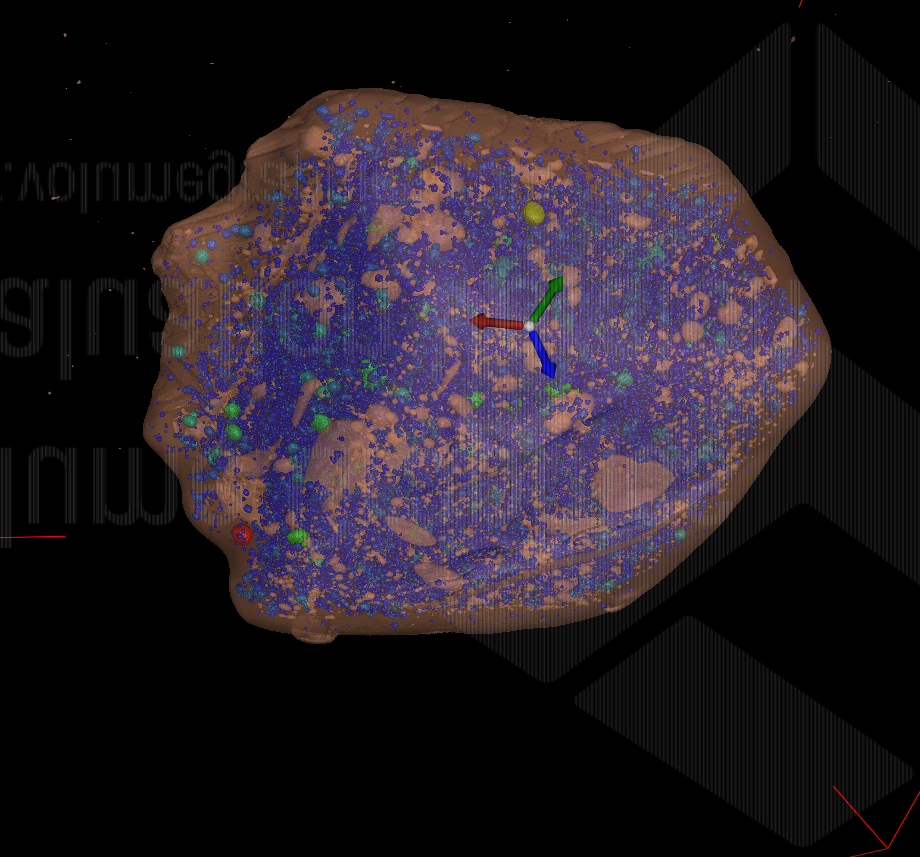

As you can see the insides of the candy are fully revealed in the scan without having to cut them up. Every aspect of the materials inside can be measured, from the thickness of the chocolate to the density of the crispy center. See here some more examples of other familiar mini bars.

It’s easy to see the layer of caramel that differentiates the one bar from the other, and in the next example you can see the porosity of the caramel mousse modeled from which the air content of each individual bar can be measured . How else could you do that?

While it has to be said that no one has come up with a better quality assurance method to replace actually eating the finished product; If you do need an accurate fast and non destructive way of examining foodstuffs; Give us a call.