Followers of the Wenzel America Blog might remember last month I recounted how by using the Wenzel CT machine in our Wixom Michigan Lab I was able to preserve forever a rare component for my 1972 Triumph Trident.

Well since I wrote that piece my Triumph has benefited further from the use of the CT scanner though rather like most of my customers it wasn’t by my choosing that I found myself looking for a solution to a problem.

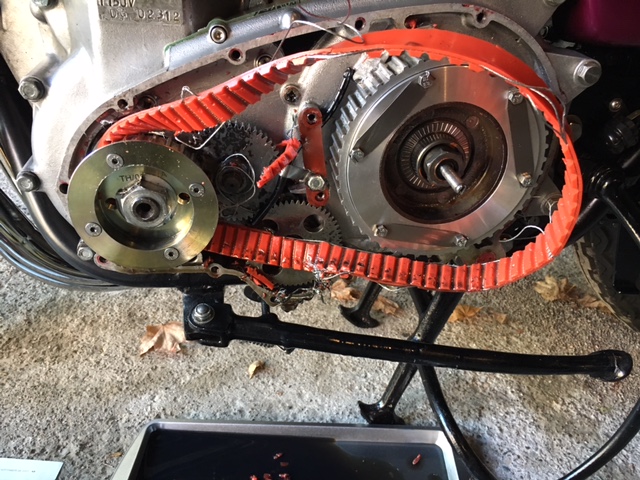

I’d fitted the restored bike with a modern belt drive system that connects the engine with the gearbox. This doesn’t alter the appearance of the bike as its hidden under a cover on the side of the engine.

Sometimes newer doesn’t mean better though because the belt system destroyed itself in a spectacular manner and resulted in me needing a ride home in a recovery vehicle.

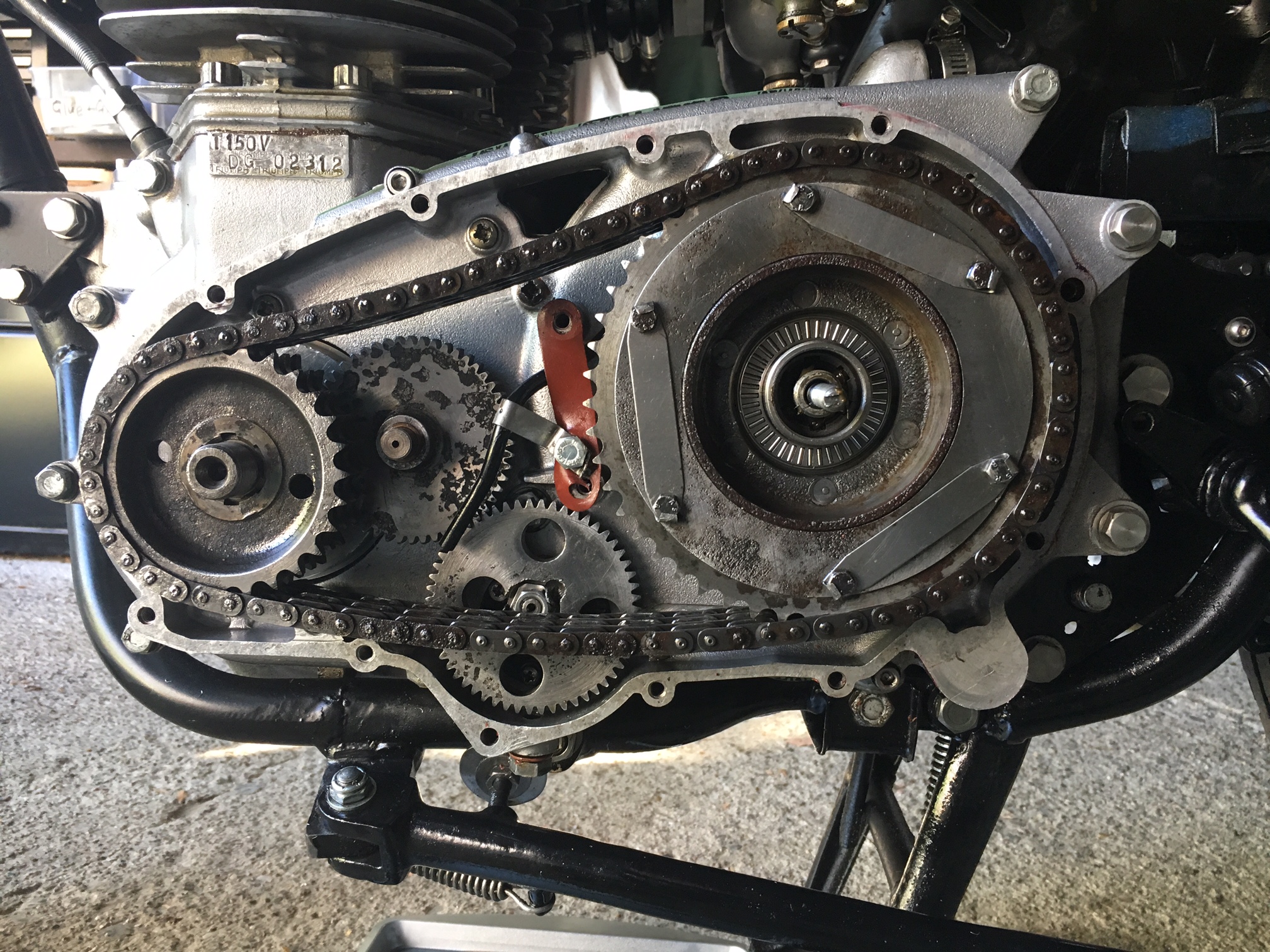

I’m still in discussions with the makers of the belt system and don’t want to fit another until I know what happened so I decided to re-fit the original chain drive.

I’m still in discussions with the makers of the belt system and don’t want to fit another until I know what happened so I decided to re-fit the original chain drive.

The problem then was that I’d fitted the new belt because I was fearful there was a defect such as a crack in the 45-year-old drive wheels that could lead to a more catastrophic and dangerous failure.

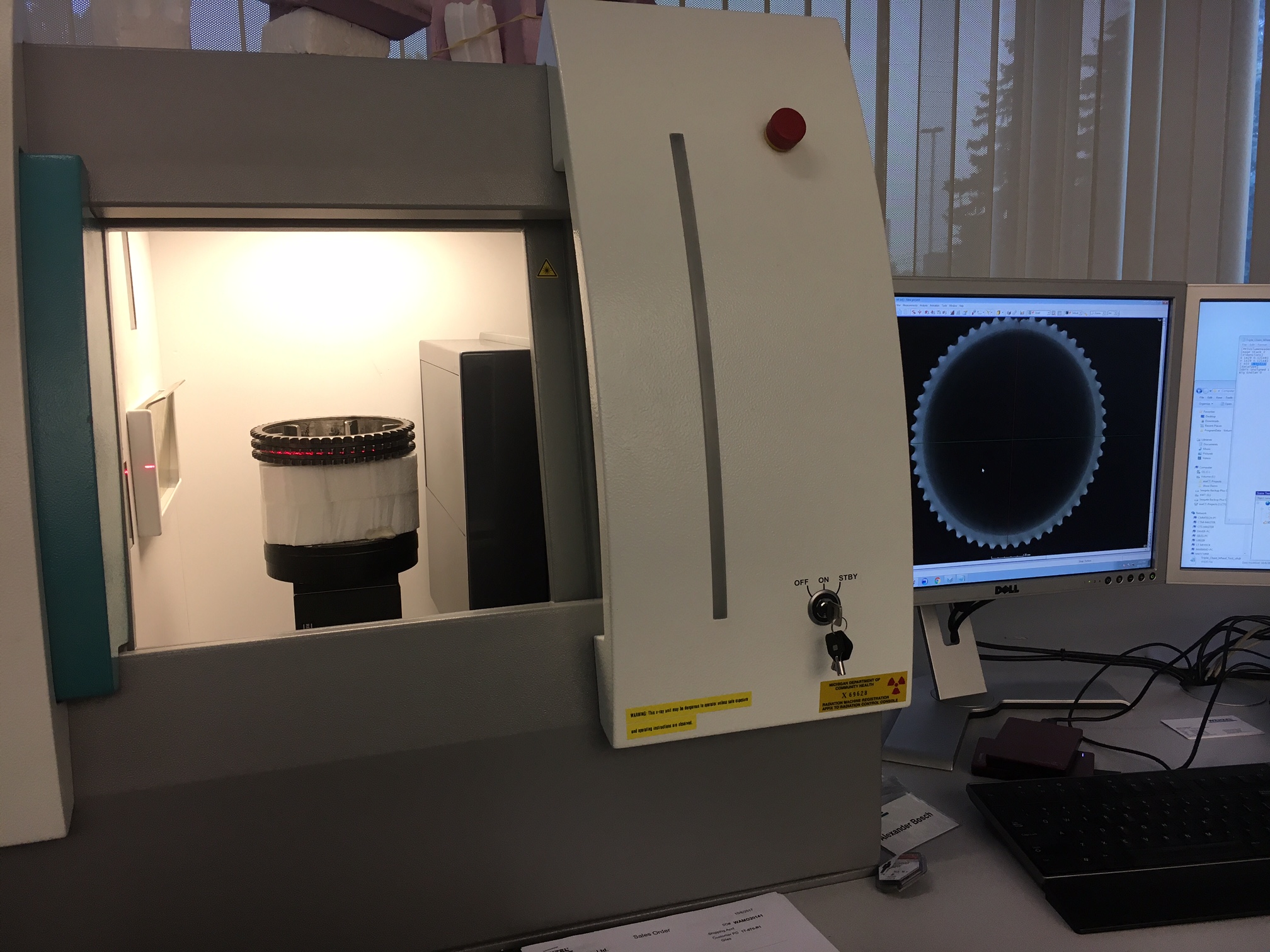

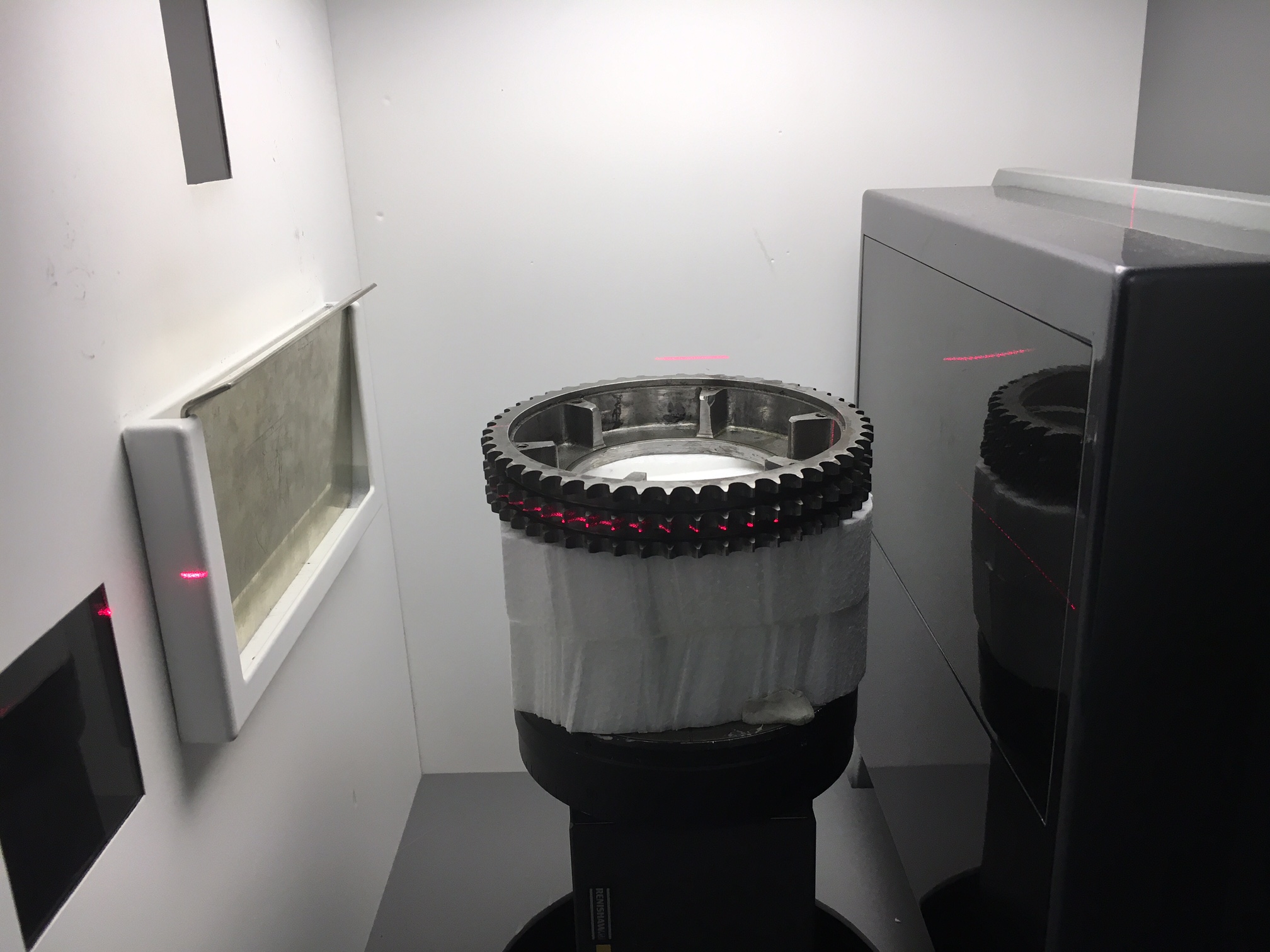

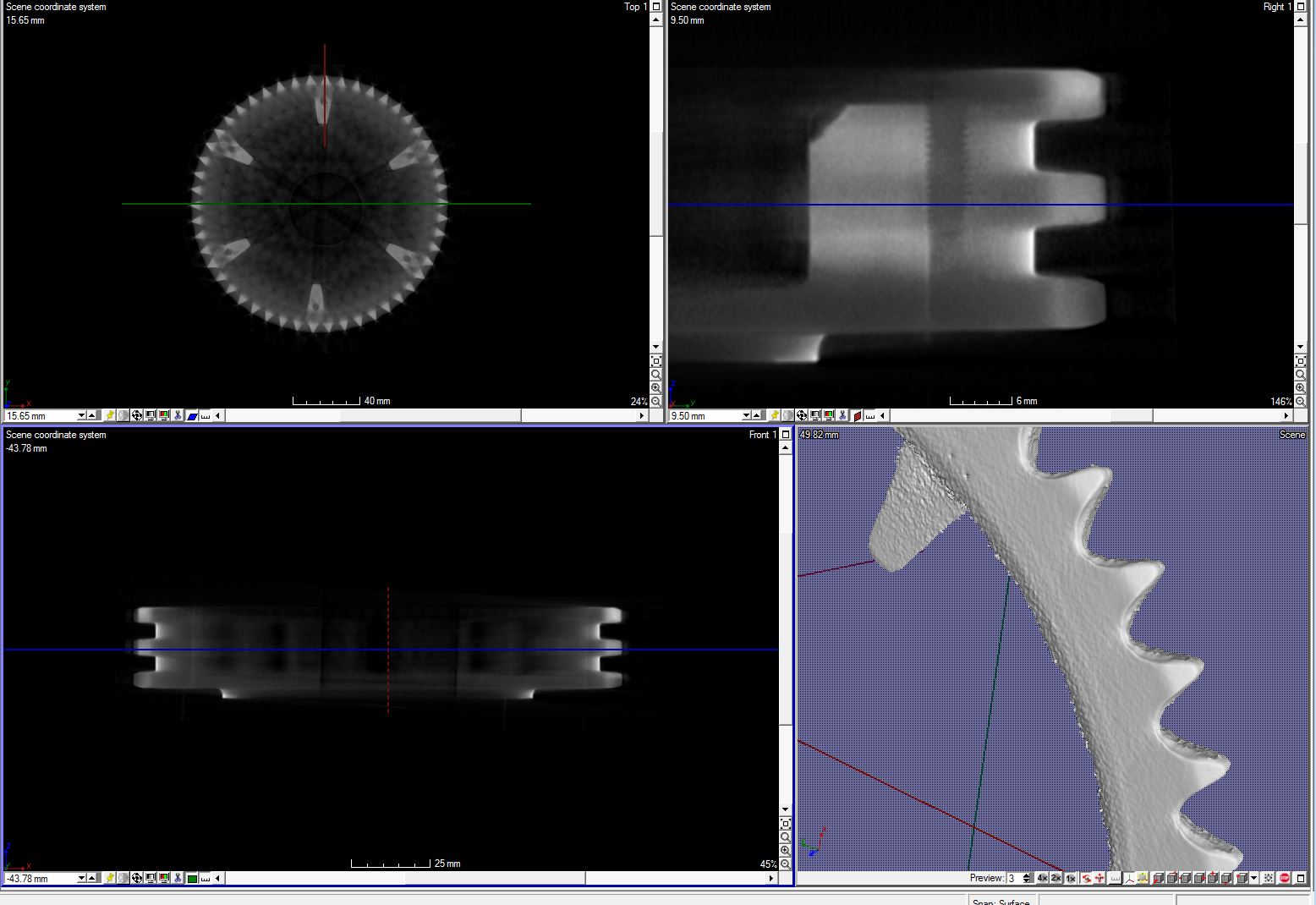

At this point I found myself in the same place many of my customers find themselves when they call up Wenzel America’s CT scanning service; I needed to do some non-destructive testing (NTD) to achieve some peace of mind. If part of the old system is going to break it will be the cast iron rear chain wheel. Such a failure can be truly catastrophic and result in an accident so I took it to the Wenzel lab and scanned it in the exaCT M.

The CT system works by taking thousands of X-Ray pictures and reconstructing the scanned part in 3D, not just on its surface but all the way through the material so that if there are internal defects such as cracks or voids they will be visible.

Careful examination of the chain wheel with analysis software gave me the reassurance that I had nothing to worry about. The integrity of the wheel was good.A morning’s work saw the original chain drive system re-fitted and I was back on the road. If anyone else is concerned about using a part that might have defects in it or sending one to a customer – give us a call, we can help you get peace of mind.