Congratulations depending upon the reason you need to buy a CMM, I am going to try to review some items you should consider when thinking about buying a CMM for the first time. Some of these may be good checks, even if you are already a CMM owner. First a quick checklist for you to consider.

QUESTIONS FIRST: WHY?

1. Why do you need to buy the CMM? ___________

2. What is driving the purchase? ____________

3. Is it a regulatory requirement? ____________

4. Is it a requirement for a job I’m hoping to bid on? ____________

5. Is it addressing throughput issues? ____________

6. Am I going to be measuring larger parts so I need a big machine? ____________

7. Am I measuring gears? ____________

8. Am I measuring turbine blades? ____________

9. Am I measuring sheet metal? ____________

10. Are the inspection results specific and I need a measuring instrument with tight tolerances?____________

Please take a moment and either make a mental list, write down your priority or whatever your answers are that are driving this need. The “Why” you need the CMM is important and flows in to the “What” you need to measure.

NOW THE WHAT?

- What am I supposed to measure (GD&T callouts) on the part? ____________

- What is the size and weight of my part? ____________

- What is the tightest tolerance that is needed to be checked? ____________

- What is the frequency of checks or quantity of parts to be checked? ____________

- What are my reporting requirements? ____________

- What is my budget?____________

FRAME (BRIDGE, SHOP FLOOR, HORIZONTAL, LARGE)

Coordinate Measuring Machines or CMM’s come in a variety of shapes or sizes. We are only going to consider CNC CMMs. Manual CMMs would fall in the category of portable measuring arms and other options that require an operator to move the sensor around the part.

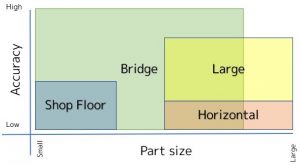

The frame carries the sensors and basically is the largest influencer to the inherent accuracy of the machine. The frame measuring volume may be in mm. So a 1200 x 2000 x 1000mm volume will be 47 x 79 x 39″. This is rough idea of what size part can fit in the volume. I have included a rough graphic on what each frame can do in regards to accuracy and part size.

The Bridge frames, usually are the most accurate and the most general purpose. Shop Floor machines are built so that they are less dependent on s shop air and take into consideration operating in the shop environment without a special room or facilities.

Horizontal Arm Machines (HAM) are typically used in situations where accuracy is still important, (Maybe more than a Portable Arm, or Sensor on a Robot) but more size is needed. In some cases, where the HAM is flush to the floor, foundations consideration arise. Finally,

Large CMMs still retain a high accuracy, but allow larger parts to be measured. Either in bridge style, where the guide ways are in the floor, or Gantry style. You will definitely need to consider a foundation as, the it acts as the table and as support for the machine.

SENSORS (TOP END SCANNING, SCANNING, LASERS)

When considering sensors, the Top End scanning solutions usually offer Premium accuracy, a wide variety of tool carrying capacity and throughput. Regular scanning, Is affordable, gives you increased accuracy, and flexibility with a scanning sensor on an articulating sensor holder. Finally, lasers, optical, and non-contact sensors allow a wide variety of options when measuring. Large data point collection, (Point Clouds!), reverse engineering possibilities, all at the expense of some accuracy.

A moment on scanning. If you want to be the most confident in the data you are collecting on your part, then you will tactile scan the part. Basically, in the time it takes you to touch trigger 4 points, you can scan the feature. This gives you up to 4000pts / sec. This starts to give you form information as well as the size and position. Tactile scanning sensors, in general, provide the tightest accuracy specifications for a CMM

I have not detailed out the basic touch trigger probing options, fixed or articulated, because that is the basic “must have” of a CMM. You have to be able to touch / scan the part for a CMM to be effective.

PART ONE – WRAP UP

This wraps up “I need to buy a CMM…” (Part One). The main takeaway is Why and What you are going to measure. This helps determine what choices you make next. I tried to give you a barebones checklist that you can use when talking to your CMM WENZEL partner.

Need to buy a CMM…” (Part Two) coming soon.