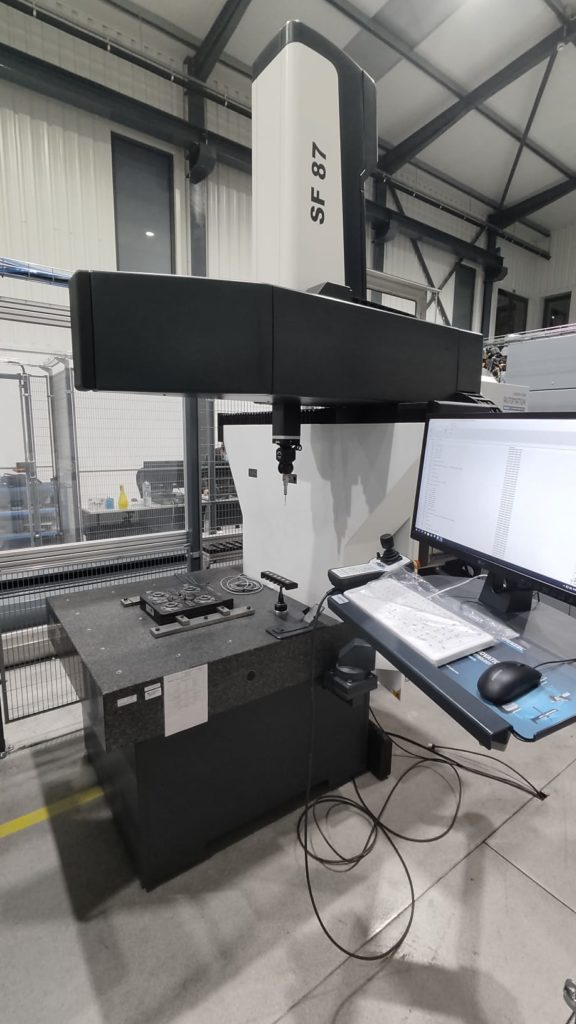

Fully automatic measurement with the WENZEL SF87

By using a special shop floor measuring machine from WENZEL in the production process, PLANIMOLDE has been able to significantly increase its measuring throughput. The Portuguese manufacturer of high-quality injection molds relies on the SF 87 coordinate measuring machine and has integrated it fully into the production cell.

Every day, the company produces high-quality components for the automotive and plastics industries, for medical technology as well as electronic components, household goods and toys. “It is important to us to constantly improve the quality level of our product range and our services,” explains Managing Director Telmo Ferraz. “That’s why we were looking for a new solution

that could map the measuring process not only in the measuring room but also directly on the production line.”

High measurement throughput and perfect accessibility

The contact with WENZEL came about through ‘MICROSENSE Industrial Metrology’, WENZEL’s sales and service partner for the Portuguese market. In addition to the many years of trustful cooperation between PLANIMOLDE and MICROSENSE, the SF 87 coordinate measuring machine quickly checked all the boxes with its sophisticated design. “Due to its open structure in terms of accessibility

and small footprint, the SF 87 is optimally suited for use in the production line and placement by a robot,” enthuses Pedro Pereira, Manager at MICROSENSE. The required accuracy of 10 µm is

no problem for the WENZEL metrology system, even under the temperature conditions outside the measuring room.

“Manufacturing high-quality injection molds and producing high-quality plastic parts, naturally in close cooperation with our customers, is one of the principles of our philosophy,” sums up Telmo Ferraz. “It goes without saying that we strictly adhere to the requirements of our customers with regard to technical specifications, and this can be documented seamlessly with our new measuring solution”.

The SF 87 Benefits

- Suitable for workshop and production use with temperature compensation.

- Large measuring volume with small footprint and low operating costs with no compressed air required.

- Ergonomic and user-friendly, bionic structures and massless weight compensation with turntable options.

- Flexible and universal use thanks to multi-sensor capability (optical and tactile) with 5-axis measuring technology.

- Integration into the line and into automation processes: WENZEL-Automation-Interface can be equipped from three sides.

Automated measurement & manufacturing processes

The strategic involvement of ISICOM – Robotea, which was responsible for integrating the automation of the entire cell with its SolidSET CELL solution was also crucial to the success of the

project. This made it possible to manage in a single system the part operations for the CNC machines (milling machines, coordinate measuring machines, EDM Machines, robot arms, cleaning

devices, I/O active devices). All fixturing (its50-80, UPC) are also managed by SolidSET, releasing the manager from the process details and allowing an advance preparation of machine jobs.

The SF 87 at this year’s IMTS 2022

We would like to invite you to this year’s IMTS – International Manufacturing Technology Show. We will be showcasing all the metrology systems as shown here on the right! As well as the new handheld mScan and XO CMM.

You will have the opportunity to talk to our expert team and find out what is the best solution for your needs.

Not only that you will experience the latest technologies, enjoying more than 2000 booths that have brought their best just for you!

WENZEL’s CEO, Dr. Heike Wenzel, will also be there as well as the new GT Series Business Develop Manager, Mr. Stefan Staab.

Don’t miss this year’s IMTS 2022 in Chicago, Illinois.