There is a bright future ahead of young Americans wanting to work in manufacturing and it’s exciting.

I grew up in the UK and as a Mechanical Engineering Graduate in the 1980s it was depressing to be in a place where it was generally accepted that the once great manufacturing industries that had at one time defined the country were in terminal decline, that the outsourcing of jobs was inevitable and that my chosen career wasn’t in demand any more. Imagine my further disappointment on moving to Michigan USA at the turn of the century to find myself at the start of Michigan’s “lost decade” when just like I’d experienced before in England, the auto industry was in decline, jobs were going overseas and factories were being closed down.

But now, for the first time in my adult lifetime I really think the tide has turned. I’m excited by what I’m seeing around me and delighted to have the opportunity to be involved.

At this time, we have the Federal, State and local governments all aligned with promises, policies and initiatives that are bringing back manufacturing to the heartland and as recent investments show they have investment capital on the same page.

I recently participated in a meeting of advanced manufacturing industry leaders in which we discussed the challenges of the day and in particular what were the barriers to growth. Every one of the businesses involved sited lack of suitably skilled employees at every level from machine operators to technical salespeople as being their biggest challenge.

We at Wenzel America are not exempt from this ourselves as we continue our growth alongside our manufacturing customer base so it was not without a degree of self interest that we hosted, for the 3rd year a Manufacturing Day (MfgDay) event which is an event intended to inspire students to look at a career in manufacturing.

We take this event very seriously because we view the development of local techinically skilled talent as a vital part of our growth and if we do not have students interested in and enthusiastic about quality and measurement technology we are going to lose out to other companies even if the students choose a career in manufacturing.

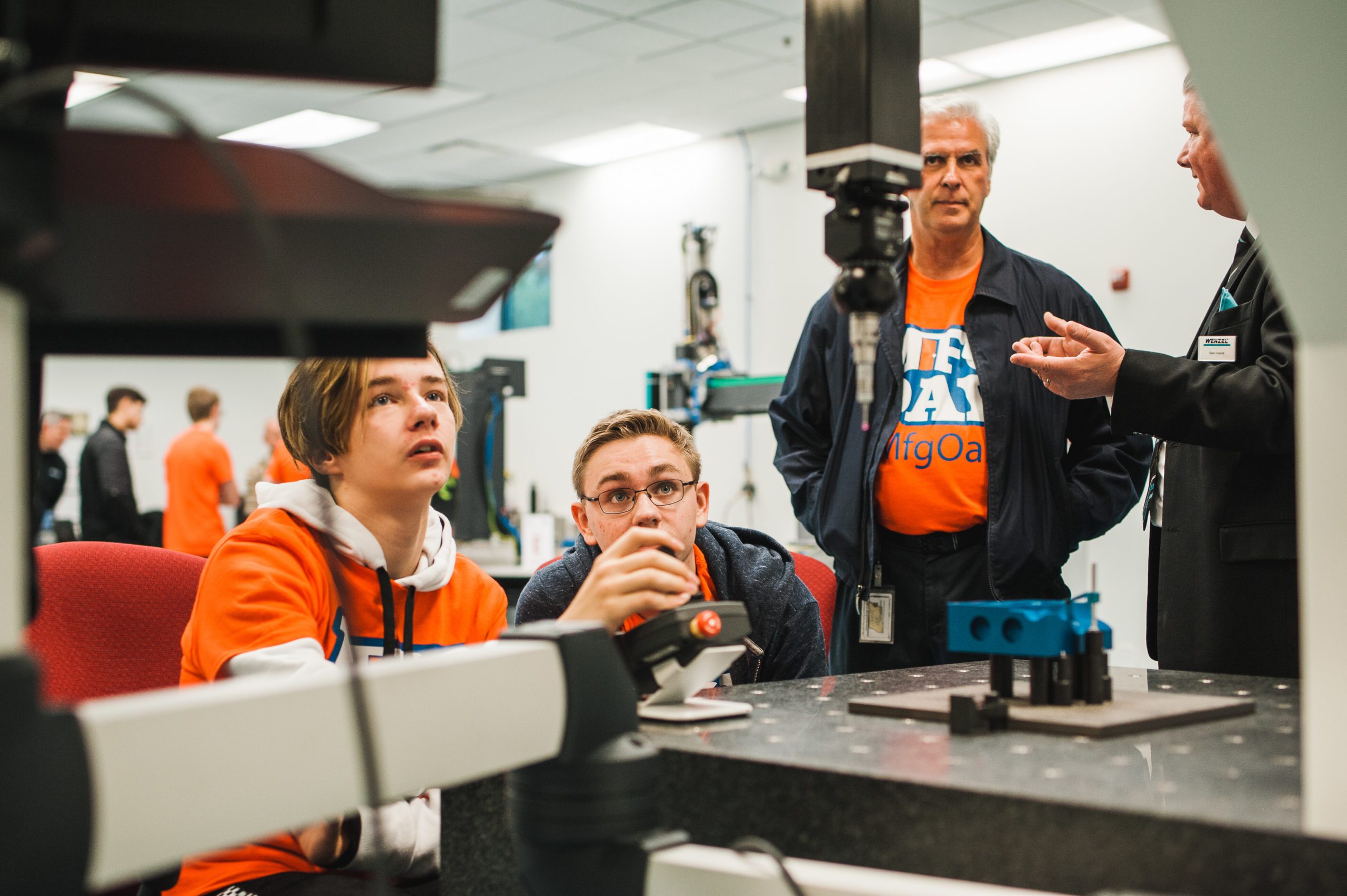

In the end, I think we did a good job of exposing the students who visited us from the Oakland Schools Technical Campus to a wide variety of technologies, educating them a little and hopefully interesting them a lot.

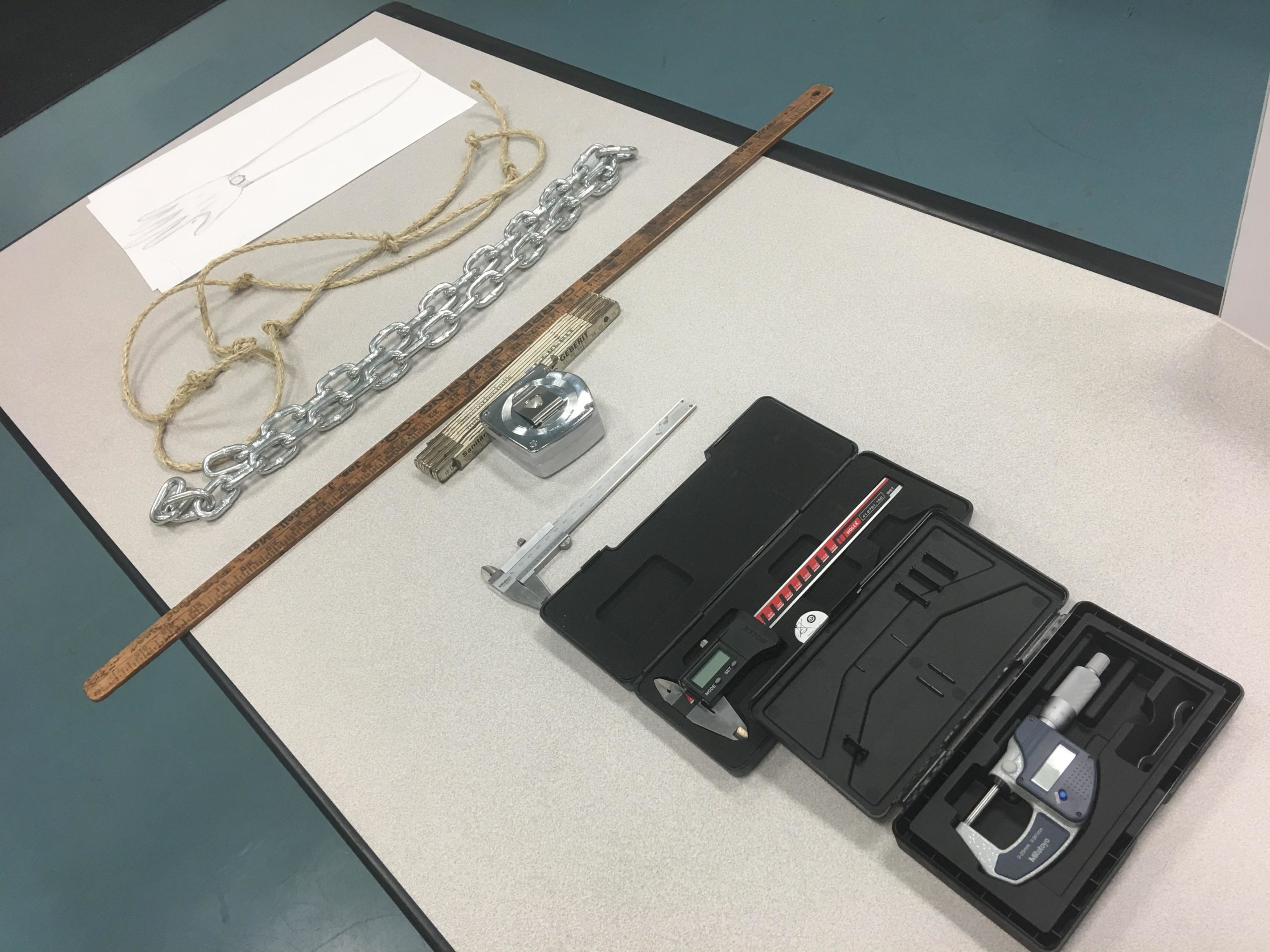

First of all we asked of them the question “why do you need to measure things at all” going back to the challenges early civilizations had as they learned to build and make machines, through the era aof the blacksmith to the evolution of manufacturing industry and the production line to virtual design and manufacture.

Along the way they got to see basic measuring tools like chains, tape measures, and calipers though advanced CMMs driven by computer to industrial CT technology that can see inside assemblies and measure then without taking them apart. Finally, they got to see the link between the “virtual” factory and real life curtesy of our partners C&R Engineering with their demonstration of the “Virtual Factory” viewed through 3D Goggles. They all went away both excited and interested in our technology.

According to Randy Sortzi, Mechatronics Instructor at Oakland Schools Technical Campus and chaperone for the day: “The Students were fascinated by what they saw and had no idea before the visit how much fun Measurement technologies were”

A very worthwhile investment of time on Wenzel America’s part in my view.