Yes, Barkhausen is the name of an actual effect which was named after Heinrich Georg Barkhausen, a scientist, of course. Allow me to explain in layman’s terms what Barkhausen Noise Analysis (BNA) is all about since there’s a possibility you might need it in your near future.

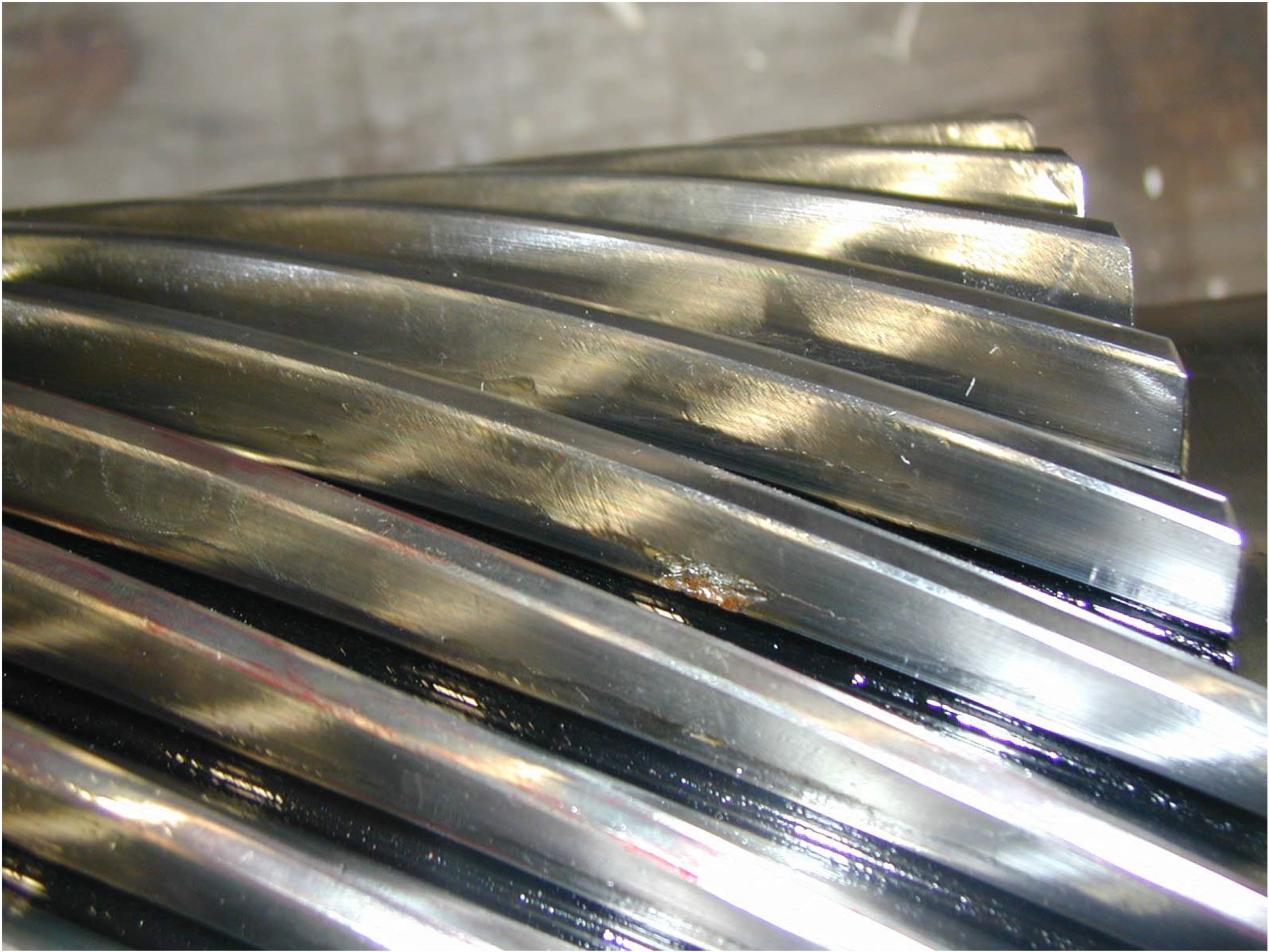

This is because gear failure can be caused from grinding burn. The lifetime of the product is shortened due to effects like pitting. It is beneficial, then, to inspect your parts for grinding burn to minimize waste and save time in your process.

In short, it is a non-destructive evaluation for grinding damage detection, case depth analysis, heat treat defect detection, and residual stress measurement from effects such as shot peening and chrome plating.

How is it done then? Well, a lot of metals used for gearing are ferromagnetic, meaning they posses high magnetic permeability making them strongly attracted to either pole of a magnet. These ferromagnetic materials are comprised of magnetic domains which you can think of as the material being divided into extremely small volumes with each “room” or “bubble” pointing a particular direction depending on how the atoms are arranged in that “room”. Initially, when there isn’t a magnetic field near the material, all of these magnetic domains point in random directions. Since they are all pointing in random directions, the material is not magnetic at all.

However, if a magnetic field (from a magnet) is strong enough and comes near enough to the material, these magnetic domains may start pointing in the direction of the magnetic field because this will change how the atoms are aligned in the “rooms”. Think of the magnetic field as if it were wind and the magnetic domains as wind vanes. The domains will all start pointing in one direction (the direction of the “wind”, or the magnetic field) which means the material is now magnetized.

However, if a magnetic field (from a magnet) is strong enough and comes near enough to the material, these magnetic domains may start pointing in the direction of the magnetic field because this will change how the atoms are aligned in the “rooms”. Think of the magnetic field as if it were wind and the magnetic domains as wind vanes. The domains will all start pointing in one direction (the direction of the “wind”, or the magnetic field) which means the material is now magnetized.

This is why, when you put a paper clip on a magnet, you can then hang another paper clip on the original paper clip. Each clip is magnetizing the next clip (up to a point!)

Interestingly enough, these same concepts may be used to understand how metal detectors work.

Now, the magnetic domains are moving – so what? Well, as each room “moves”, a change will be felt at the borders of these domains which would be the “walls” of these “rooms”. This change can be interpreted as an electric pulse which, when hooked to an amplifier, can be heard! There is also a numerical output, though, measured in units of magnetoelastic parameters (mp).

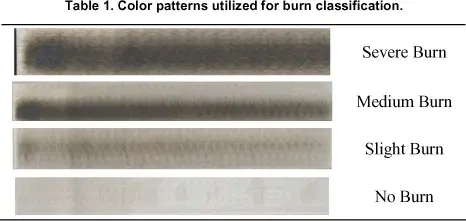

BNA is the latest in non-destructive testing (NDT). Nital etching, in comparison, uses chemicals to look at differing shades of grey on the material. This not only makes it subjective but not as sensitive, repeatable, or fast as BNA. Furthermore, nital etching requires scrapping parts for analysis and also imposes a safety factor for the operator due to the chemicals needed. This makes BNA the more favorable analysis method.

BNA is the latest in non-destructive testing (NDT). Nital etching, in comparison, uses chemicals to look at differing shades of grey on the material. This not only makes it subjective but not as sensitive, repeatable, or fast as BNA. Furthermore, nital etching requires scrapping parts for analysis and also imposes a safety factor for the operator due to the chemicals needed. This makes BNA the more favorable analysis method.

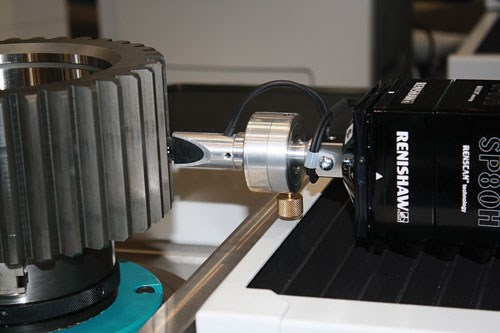

Why let you know how this works? To also let you know that Wenzel can help you save time, money, and energy. If you need BNA for your gears, our GMMs can be equipped with BNA sensors, which helps you automate your process and noise analysis results right next to your lead and profile charts.

Why let you know how this works? To also let you know that Wenzel can help you save time, money, and energy. If you need BNA for your gears, our GMMs can be equipped with BNA sensors, which helps you automate your process and noise analysis results right next to your lead and profile charts.

If you want me to show you how we can do BNA on a spur or helical gear, contact me here or tweet me @GearMarks. Don’t forget to visit our site here as well. #Cheers4gears!