Wenzel America is taking on the toughest metrology questions of automotive, medical and turbine parts manufacturers in a never-before-seen, side-by-side comparison of seven different measurement methods. Dubbed Metrology Matters Live, their customer-focused Open House will take place June 17th, 2016 from 7am – 3pm and again on June 18th, 2016 from 10am – 7pm at the Wenzel America Headquarters in Wixom, Michigan.

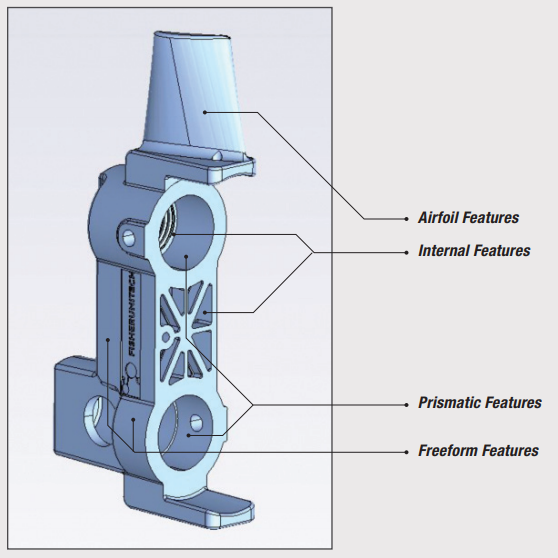

“We’ve teamed up with Fisher-Unitech to combine our knowledge of metrology applications and their experience with Solidworks CAD software, and Stratasys 3D Printers to design and manufacture a one-of-a-kind hybrid part that we will then measure on seven different measurement systems,” explained Wenzel America’s President, Andy Woodward.

Medical, automotive, turbine and other part manufacturers have many of the same questions about metrology and measurement. Figuring out which inspection technology meets their needs is often a mystery.

“These are questions manufacturers ask and answers they need to know when purchasing a CMM or other metrology equipment. It’s something that’s never been done but we think our customers deserve to see first hand what each measurement technology is best suited for,” added Wenzel America’s Drew Shemenski.

Attendees will get to see live measurement processes, with comparative results, on seven different machines including a touch-trigger CMM, a tactile-scanning Coordinate Measuring Machine, a 5-axis scanning CMM as well as white light scanner inspection, laser scanning, high-speed scanning and CT inspection.(Updated 31JUL17)