Fast reaction times and direct feedback make measurement technology integrated into production, attractive. For the solution to be successful, mechanical engineering, ergonomics and service must result in a future-proof overall concept.

For some time now, metrology has been undergoing a change from the measuring room to the production environment or to the fully automated production line. The exciting question now is, what does this mean for the measuring machine? Or in a broader sense: What does this mean for the measuring solution in the future? How do we make the integrated measurement technology attractive?

Many manufacturers appreciate the advantages of measurement in production. The material flow is easier to handle, the result is available much faster to the people who can intervene immediately – the workers. This reduces waste because the worker can counteract trends before it is too late.

What is the difference between a production and measuring room?

The requirements of the production process differs in important aspects from the quality area, especially the operation, the environment, and the required reliability. Ideally, the worker carries out the measurement himself near the production machine. Simple operation and immediate availability, easily readable results leave time for the essential, the production. This is where software with intuitive controls and clear reports and trend analyses is in demand. There are already solutions available today that distinguish between programmer and operator and partially automate programming.

Go with the flow

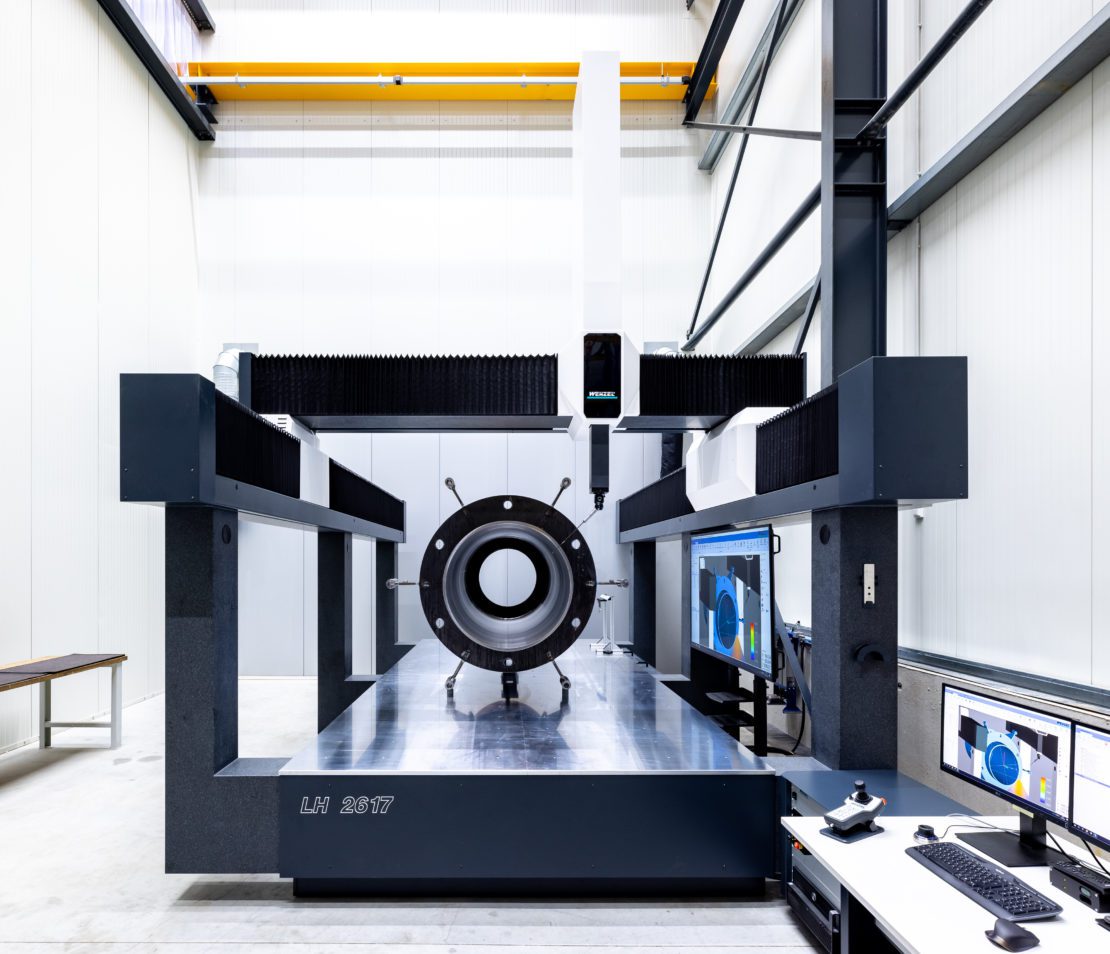

For short distances, the measuring machine is close to the production machine and therefore a small footprint is mandatory. With modern production methods and design technologies such as topology optimization and FEM simulations, the machines can be built extremely compact and light and the control and electronics can be integrated into the machine.

What makes the difference?

However, it is often small things like a cleverly integrated probe changer for maximum measuring surface that make the difference for the operator. In the case of gantry machines, for example, a level finish of the base plate on all sides can be decisive for easy loading. This means that the machine can be easily integrated into the existing hall in any orientation.

ergonomically designed for easy operation.

Measurement technology in step with production

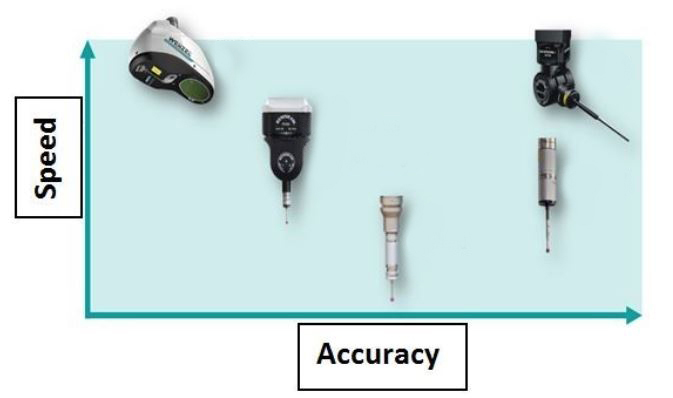

In production, the cycle determines the speed, whereas previously the focus was on accurate and traceable measurement. How do you deal with this now? The more accurate the measurement, the more time is usually needed! Fortunately with a high-precision measuring systems the measurement can be imaged via speedy head movement, and optical sensors can also measure large areas quickly with sufficient accuracy.

And if this is still not enough, you can use a fast comparator or operate the measuring machines in a faster mode. Here, repeatability is maintained, and trends can still be observed. The measurements are compared in random sample measurements against exact absolute measurement values.

The future – life is what happens while making plans

Production is also undergoing profound changes. Rapid series changes and demographic change are fundamentally altering the framework conditions. Therefore, it is important to find a sustainable solution:

- Flexibility – Retrofitting for sensor technology and easy relocation offers adaptability for a new series

- Automation capability – Preconfigured automation solutions from the manufacturer or pre-equipment makes the machine easily expandable

- Monitoring possibilities – Online monitoring tools are already standard and provide the basis for predictive maintenance

Reliability through excellent and predictable service

Even the most beautiful machine is of no use when it is stationary. Through a service contract teams can plan with a reliable and predictable schedule, which is great in production where people are use to plan in advance. In the end, the overall package is decisive: Of course, an attractive purchase price is important, but at least as important are reasonable operating costs (cost of ownership) and availability as soon as the machine is in regular operation.

In addition to reliable machine construction, and worldwide availability of parts, the manufacturers already offer modular service programs that offer many advantages:

- Latest Software

- Guaranteed response time

- Plannable costs

- Extended warranties

It is precisely these aspects that accompany the user in everyday operations.

Robust mechanical engineering

The production environments we encounter at customers’ facilities are as diverse as the parts they produce: in machine design, workshop-suited machines are designed with a number of new aspects compared to the measuring room.

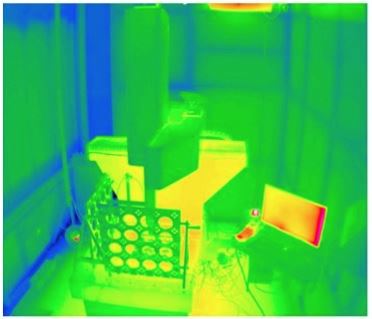

- Temperature behavior: The choice of material and connection of the individual components is essential to ensure that the machine is changed as evenly as possible. The residual errors are then recorded in the climate chamber in elaborate measurements (see illustration) and can be deducted by compensation during measurement.

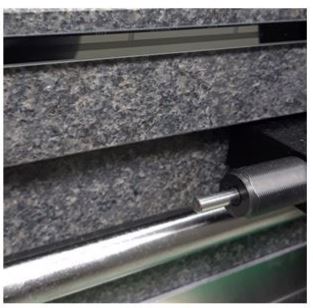

- 24/7 operation: Drive and guide systems are used that are as proven and robust as possible. The mounting position can also be decisive for dirt resistance, such as vertical mounting of the measuring systems and protected drive rods (see illustration).

- vibrations: Many years of experience with customers show that air bearings are also suitable for the production environment. Air-sprung active damping or robust linear guides are used in difficult environments.

In the end the package decides

Of course, high-quality mechanical engineering with sensor technology tailored to the respective application is a prerequisite. In order to create a complete measuring solution, there are also

- Ergonomics: the solution is efficient when it fits into the material flow

- Operating concept: the operator can operate the solution reliably

- Future-proof: the machine can be adapt to new processes and expanded with modern sensor technology

- Cost-Of-Ownership: Reliable and plannable service with modern software makes everyday life easier

If the package is right, you will enjoy your measurement solution.

If the package is right, you will enjoy your measurement solution.

The new SF 87 Coordinate Measuring Machine is the universal measuring machine for the production environment. It requires little floor space and is ideal for a large part of the metal cutting and forming industry.

Features of the SF 87

- Maximum driving dynamics for maximum productivity.

- High measuring volume, matched to production machines.

- Compact design with small footprint.

- Flexible and mobile for use in the workshop.

- Maximum stiffness with minimum dead weight due to bionic design.

Benefits of the SF 87

- Suitable for workshop and production use with temperature compensation: active damping as an option.

- Excellent price-performance ratio: large measuring volume with small footprint and low operating costs with no compressed air required.

- Modern machine design: ergonomic and user-friendly, bionic structures and massless weight compensation with turntable options.

- Flexible and universal use: multi-sensor capable (optical and tactile) with 5-axis measuring technology. These machines are also available with matching probe changing units.

- Integration into the line and into an automated process: WENZEL-Automation-Interface can be equipped from three sides.

Looking for a throughput solution that fits your shop floor without compromising on the quality of the results you need. You cannot go wrong with the SF 87

Contact us to find out what integrated measurement technology options there are for your needs. Phone our experts to schedule a demo and get your questions answered. The other way to stay up to date with the latest information is to follow us on LinkedIn! You are invited to our IMTS booth in Chicago where you will experience the finest WENZEL technology.