MEASURING TURBINE BLADES QUICK AND EASY WITH WM|QUARTIS

This is Part 1 of WENZEL software solutions to learn about the basics of the WM | QUARTIS. In our series #allaboutblades you discovered the different aspect of blades and today you will learn the details of blade measuring within our popular WM | QUARTIS.

In our customer’s Quartis training sessions we often hear: “Quartis is easy to use and very intuitive software!” or “Quartis is fully compatible and works with even wider variety of sensors than other software in the market.” Comments like these inspired us to write this blog and share with you a deep dive into why Quartis is the software you would love.

BEFORE YOU START MEASURING

Before you start measuring your parts, it is good to plan your task to ensure that you are efficient throughout the process. The ultimate goal is to measure #morepartsfaster.

STEP 1: GATHER YOUR RESOURCES

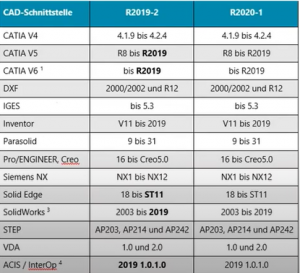

- CAD model: What format is my model, Quartis can import CATIA , DXF, IGES, Inventor, Parasolid, Pro/Enginieer, Creo, Siemmens NX,Solid Edge, SolidWorks, STEP, VDA, ACIS/OnterOp etc.

- Part print: Having the model is great but sometimes you need the print to clearly define the requirements.

Programming from a CAD model

is the most efficient way to use

modern metrology software like WM|Quartis

STEP 2: THE OUTPUTS

- Do you need to save the report as a pdf on your server?

- Should you send the data out in Excel or in any other format?

- Are there any customer specific requirements you need to plan for?

Quartis has a host of tools to help you create custom templates for your reports and file formats to meet various customer needs.

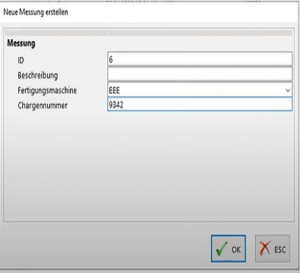

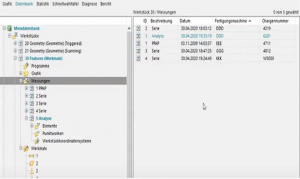

Customizing your results: When you want to add a customer name, article number, current part, batch number, production machine, process id, these items can be imbedded during measurement and stored in the Quartis database.

These unique identifiers are available to report, sort and filter your data now or at any time in the future.

Your pre-planning is now done, let the measuring begin!

TIME FOR A CLOSER LOOK AT WM|QUARTIS

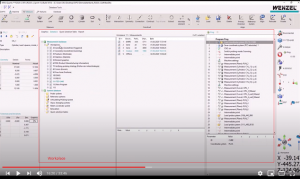

WM|Quartis follows the Microsoft interface best practices to present a modern dynamic GUI to the user. The toolbars efficiently present all that you need to complete your measuring tasks.

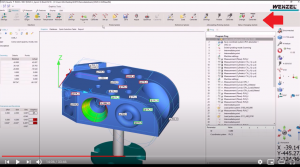

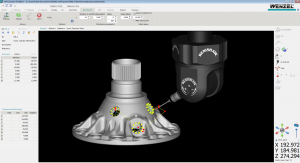

Centered on the screen, Quartis guides you through the necessary tasks for the measurement. As you move through, the toolbars are naturally adjusting to present the user with the most relevant items for the measuring task at hand. On the right, the window presents the status of your machine, workpiece, measurement, probe, or other related information. On the left the element will show the user more detail of the CAD model as you interact with it.

LET’S GET MEASURING!

Works flows in Quartis from left to right which makes it simple to adapt to a variety metrology challenges.

In the Measuring bar we see all the functionalities we need to measure whether its interacting with CAD or constructing elements. The next natural step is as simple as choosing your task and clicking on the CAD model.

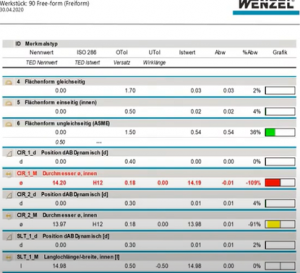

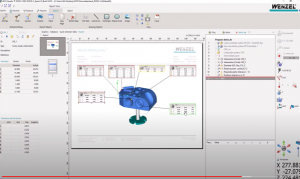

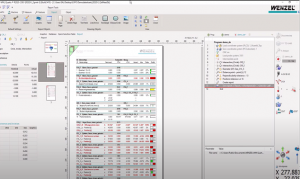

In the Features bar we now address the print requirements and what we need to evaluate. You simply select a feature you want to evaluate (straightness, symmetry, position, etc.), choose the element you need to measure and we are on our way! If you want to go a little further, advanced settings to customize your measurement tactics are available too.

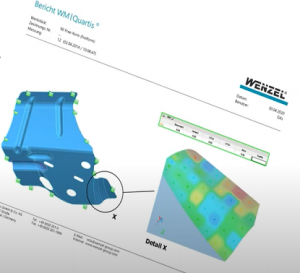

Formatting your report is simple and easy. Open the Report bar and choose from a variety of templates or create your own. Quartis gives you the ability to customize the views and how the data is presented making it simple to tailor your output to a specific customer or industry format. Select how you want to save your report and the job is done.

IN SUMMARY

While many CMM software’s have evolved and grown to work in the Windows environment, Quartis is the first software to be designed using the trend-setting Microsoft® Office Fluent™ user interface. As you could see in this blog, WM| Quartis is a measuring software with an uncluttered, flexible and result orientated workspace that reduces distraction for users so they can spend more time and energy focused on their work. Measurement results can now be generated even faster and easier.

- WM Quartis is easy to learn

- The database offers the possibility to store measurement results in a traceable way

- A wide range of standard-compliant evaluations are offered

- Path Generators allows the user to easily and quickly program complex or repetitive measurement paths, regardless of the sensor type.

- Complete machine and sensor simulation allows for an efficient off-line programming and testing environment

- Built in SPC allows you to combine process control, with CAD visualization for rich, dynamic reports.

- Import and export functions support our users

WITH WM|QUARTIS YOU CAN GENERATE MEANINGFUL RESULTS QUICK AND EASY!

Don’t miss our #allaboutblades series where our experts share everything about turbine blades and how WENZEL’s machines and software can ultimately provide solutions to your needs.