Precise measurement of large-volume tapered roller bearings is how WENZEL and the Timken Company meet and their story begins.

The Timken Company is known worldwide as a leader in the field of rolling bearings and power transmission. The founder Henry Timken is the inventor of tapered roller bearings, one of the main products of the plant in Xiangtan, China. Bearings are immensely important components in the industrial sector. Proper inspection and evaluation are the essence of quality assurance at Timken. The high quality requirements often demand accuracy in the μm range. The LHF Gear 4015 coordinate measuring machine from WENZEL plays an important role in ensuring the quality of Timken’s large taper bearings.

SCRAP REDUCED TO A MINIMUM

Timken’s shops use some manual measuring equipment to measure diameters. Manual measurement places high demands on the operator, making it prone to measurement errors, incurring higher costs and reducing production efficiency. Other properties, such as shape and position tolerance or waviness, cannot always be satisfactorily measured manually.

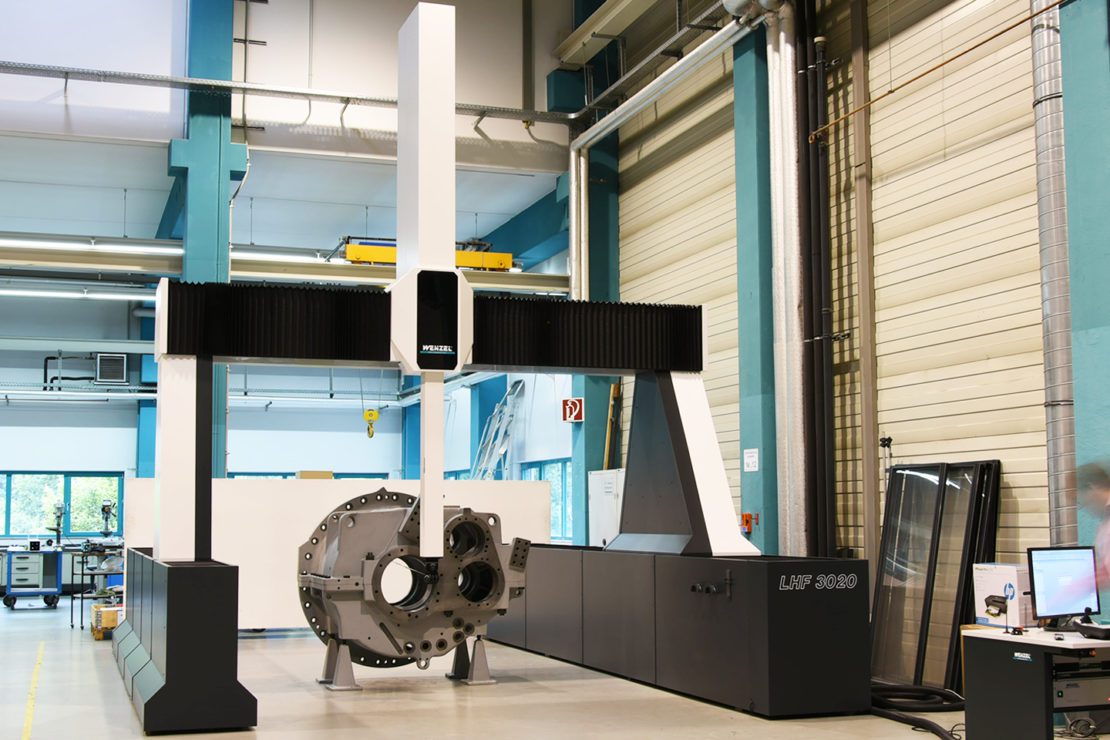

The LHF is a CNC coordinate measuring machine with air bearings on guide beams, designed for high-precision measuring of large-volume and complex workpieces. Its ground-level design allows excellent access to a large measuring range with maximum freedom of movement.

LHF series

The high-precision CMM LHF Gear from WENZEL represents the perfect solution for Timken’s quality assurance challenges. It is a measuring machine that combines the functions of coordinate metrology and gear measurement. It was specially developed for large parts and complex workpieces with high precision requirements. The CMM quickly and reliably measures rotating precision parts.

“For the parts that cannot be measured manually on the line, we use the high-precision coordinate measuring machine LHF Gear from WENZEL. It is the most important measuring device in our company and has helped us reduce scrap to a minimum,”

Mr. Zhou from Timken.

DURABLE MACHINE AND OPTIMAL SERVICE

When asked which criteria were pivotal for the decision to purchase the WENZEL measuring machine, Zhou answers: “Firstly, the selected model had to be able to continuously provide stable and accurate measuring results. Second, it had to be durable and error-free, and third, it had to provide optimal after-sales service. For this reason, we finally chose the solution from WENZEL.”

- Horizontal design of WENZEL’s LHF Series CMMs provides excellent accessibility for large parts

- Large measuring range allows the highest degree of freedom of movement.

- Dual drive in the Y-axis of the LHF provides unparalleled dynamics

- The guiding device provides unique stability.

Those are only a few of the reasons the LHF is the right machine for this application the other is the air bearing. The air bearing, specially designed for high-precision measurement of large parts and complex workpieces, ensures wear-free running and precise guidance. The beam and the guide bearing are made of dark natural granite, so these components have the same thermodynamic properties.

LOYAL PARTNERSHIP

Timken and WENZEL maintain a loyal partnership thanks to precise measurement that will always play an essential role. “In addition to Timken’s plant in Xiangtan, the LHF Gear is also used in our plant in Romania for measuring large bearings,” reports Zhou. “The stroke of the X-axis is ‘only’ 4 meters, but with the help of the rotary table, which extends the measuring stroke, a diameter of up to 4.3 meters can be achieved.” This feature is undoubtedly the icing on the cake and fulfills Timken’s desire for the widest possible measuring range.

“I have worked with the WENZEL’s experts in Germany and am well acquainted with their know-how and professionalism. In addition, I have also worked with the colleagues from WENZEL Shanghai for more than ten years. Their reliability and responsible approach have left a lasting impression on me. Over the past ten years, I have come to know the excellent performance of WENZEL’s measuring equipment and I am convinced that WENZEL is a reliable partner,” praises Zhou.