When buying a car, most people have a list of what they want as they start shopping. For some people it’s the performance of a sports car; others want serious off-road capability, or the highest fuel economy, and some are focused on safety.

But when the deal is done, and the keys are handed over, most of us wind up with a vehicle that possesses some of the attributes we wanted, but also makes the best sense for our daily lives, not to mention our budget. Because our lives are not one dimensional, our decision process can’t be either.

These same types of factors appear in our work lives as well. There are many companies and facilities that specialize and make a single part type. For these situations, a single purpose specialized inspection solution is a great choice. You can read about an example of this in our other post here. In the majority of facilities though, we are faced with a range of parts and needs that change daily, if not hourly, and require a more versatile CMM solution.

In the past, finding this versatility was often a series of compromises; between accuracy, working envelope, sensor type, ease of use, and budget. Maximizing any one of these factors would often mean sacrificing another and would ultimately reduce the overall performance of the solution.

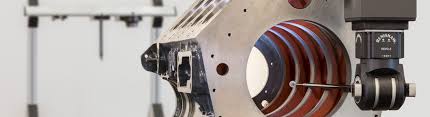

With REVO however, we can have the maximum versatility, without sacrificing any of the other attributes you want in a CMM.

With REVO however, we can have the maximum versatility, without sacrificing any of the other attributes you want in a CMM.

Accuracy: REVO uses synchronous 5 Axis motion to reduce the dynamic errors inherent in moving CMM structures. This allows you minimize measurement uncertainty in your process.

Work Envelope: The flexibility of 5 Axis motion allows the programmer to navigate around and into parts that otherwise would not fit on a particular size machine. This increases the effective work envelope of your CMM, saving you money and floor space.

Sensor Type: REVO can accommodate a variety of tactile scanning solutions, as well as a surface finish sensor, and optical scanning. This provides you a very versatile and cost effective technology platform, reducing the number of different processes and unique machines required to measure your parts.

Ease of use: REVO offers infinite positioning capabilities, but uses a simple calibration routine that eliminates the need calibrate each unique position. This makes it easy to change quickly from job to job, without spending hours building and calibrating specific tools for the next batch of parts to be checked.

Ease of use: REVO offers infinite positioning capabilities, but uses a simple calibration routine that eliminates the need calibrate each unique position. This makes it easy to change quickly from job to job, without spending hours building and calibrating specific tools for the next batch of parts to be checked.

Budget: When compared to other high accuracy scanning CMM solutions; REVO’s initial costs, throughput savings, cost of styli, and reduced downtime for probe calibrations, typically provide an ROI of 10-14 months, many times even reducing the total number of CMMs required to meet production needs.

Supporting today’s manufacturing is a challenge for inspection, requiring versatile solutions that provide good value and are simple to use. REVO is the single tool that can meet these demands and provide a platform of technology and efficiency to build your inspection capabilities around. To see the REVO in action, check out our videos below.