A few months ago we covered the topic of moving your CMM inspection to the shop floor, and some of the things to consider when doing so.

How will you monitor performance?

How will the workflow be affected?

Are there any limitations in space or environment?

These are only a few of the items to be considered when planning a project of this nature, so now let’s dig a little deeper.

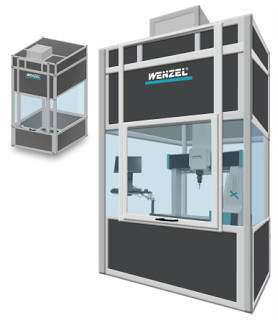

Anytime you are reshaping your plant floor, the first consideration is typically floor space. How much room do I have, and how best to use it? One strategy to make this planning process simple with a CMM is to put the machine in an enclosure.

A close fitting enclosure provides a stable environment for your machine, while also giving you a simple footprint to work with on your floor that has nearly the same footprint as the CMM itself. This makes planning floor space straightforward and easy while also providing some other benefits.

The manufacturing floor is a busy place and safety of people and equipment is always a priority. Therefore, placing your CMM in an enclosure provides protection for both your machine, and your staff, ensuring that you can maximize your up time and protect the longevity of your investment.

In many instances, shop floor CMMs are introduced in areas where staff may not be well trained in working on or around such equipment. A simple enclosure can provide a layer of safety in this instance which ensures that your people and equipment can work at maximum productivity, giving you the best ROI on your investment.

Over time, the environment of your shop floor can change significantly. You may have seasonal changes in temperature and humidity, or even changes to the ambient levels of dust, coolant, and debris. These changes are not always accounted for when purchasing equipment, and can often affect the performance on your CMM. An enclosure can help you eliminate the effects these changes have on your system and ensure consistent output, performance, and accuracy now, and for years to come.

The single biggest benefit to a CMM enclosure, is the fact that it can allow you to re-purpose a tool you may already own. Let’s say you want to build a new cell on the floor, with a CMM to handle inspection. Looking for a new “Shop Floor CMM” may add a level of cost that makes the project unrealistic for you.

But what if you could simply take your existing CMM, and move it to the shop floor? This would avoid the cost and lead time of buying new capital and help you realize the ROI of the cell even faster.

Simple, right? So what’s the catch? Many times when designing a CMM enclosure, people can over complicate things; building in automated controls, complicated power solutions, and levels of environmental controls beyond what you would do if you were putting the machine in your Inspection Room.

This can lead to the perception that CMM Enclosures are expensive and a big hassle, when in reality it may simply mean you are working with a vendor that doesn’t have a good solution for you. After all, the enclosure only needs to do two things:

Provide a barrier between the machine and the shop floor environment

Help you measure your parts with ease and confidence.

Any feature of the enclosure that doesn’t advance these two points is adding unnecessary cost and complexity, and should be avoided. A CMM enclosure can be a simple, cost effective solution to help you realize the benefits of shop floor inspection.

It can help you plan an effective workflow, protect your investment, and help you avoid buying specialized equipment that may not scale with your needs over time.

At Wenzel America, we pride ourselves on our ability to help you make the best choices for your business when it comes to inspection.

So next time you are planning a new work cell, avoid the maze of specialized solutions and let us help you find a simple, cost effective inspection solution that will support you for years to come.