When it comes to measuring turbine blades and blisks, the Wenzel CORE solution provides superlative results and value.

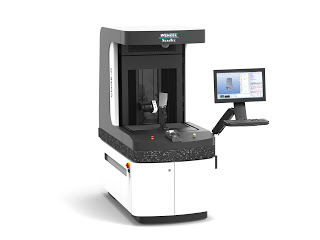

The existing CORE DS and CORE M are already known for their high throughput of measurements of turbine blades.

With high machine speeds as well as an incredible 750mm/sec scanning speed, the CORE technology is now a proven high speed quality solution for manufacturers of turbine blades.

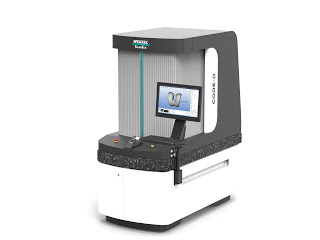

A new CORE was introduced at CONTROL 2017. The measuring volume and speed remain unchanged, but the ergonomics and usability have been optimized. This means the machine still accelerates at 4500 mm/sec and travels at 750 mm/sec. The center-drive linear motors ensures that the CORE travels smoothly and swiftly.

One difference in the new CORE are there is an integrated cover. This cover protects and improves the safety for the operator, the part and measuring system. The cover also ensures accurate measurements on highly polished parts within suboptimal lighting conditions. All these improvements still maintain the excellent accessibility to the part from three sides, making it easy to include automated loading, such as with a robotic arm.

Another improvement is the next generation sensor. Over the life of the CORE, the accuracy of the MPEP test has been improved 100%. The next gen Double-Eye white-light point sensor has been continually improved.

How exactly has it been improved? Increased resolution and better sensitivity improves the measurement process due to a larger light yield.

What hasn’t changed is the large standoff distance of 80mm, the measurement range of +/- 3mm as well as the remarkable angular acceptance of up to 85 degrees.

Additional advantages that remain are the ability to measure sharp edges and small features without tip compensation errors, (0 cosine errors), large temperature range, simultaneous control of 3 linear axis and 2 rotary axis, and the CORE still does not need an air supply.

If you were considering a CORE before, we believe you have even more reasons to improve your measurement process by the addition of the CORE and CORE technology. There is no reason not to investigate how the CORE can help improve your process.

Contact us here to schedule a demo or ask us about how the CORE can solve your metrology challenges. As always you can also visit us at www.wenzelamerica.com.

– Patrick Lanthier