Scalable process optimization in quality control

Fonderia Bassoli has been relying on metrology systems from WENZEL for the quality assurance of its die-cast parts since 2011. In their metrology lab, eight LH Series WENZEL coordinate measuring machines (CMMs) measure optimally and ensure process optimization. Another coordinate measuring machine with 3D laser sensor and an industrial computed tomography machine, the exaCT M, helps with nondestructive testing of the components.

Preventive corrections in real time

Fonderia Bassoli produces die-casting parts of numerous sizes, weighing from 50 grams to 9 kilograms, for mechanics, electro-mechanics, agriculture, electronics, and many other industries. The dimensional tolerances of the machined parts are about 13 microns.

Before the introduction of WENZEL CMMs, manual measuring devices were used, supported by a spot check on a three-dimensional measuring device in the technical office. The production batches were much smaller than today; nevertheless, waiting for the results of the measurements could easily lead to dimensional deviations and rejected parts with this time-consuming method.

By using the WENZEL CMMs, which are directly integrated into automatic lathes, the Italian company based in Luzzara, was able to significantly reduce the measuring times which resulted in an increase of cycle time and overall productivity. Furthermore, in the event of tolerance deviations, preventive and corrective interventions can be carried out in real-time thanks to the interface between the WENZEL CMM and the machine tool.

Versatile measuring and testing options

With the first project, it was essential to find the right measurement system. Different possibilities were explored: stylus masks, laser scans, optical cameras and many more. Fonderia Bassoli’s main goal was versatility without compromising on the accuracy and repeatability of the measurement process. A traditional WENZEL coordinate measuring machine met all their requirements, especially due to its flexibility.

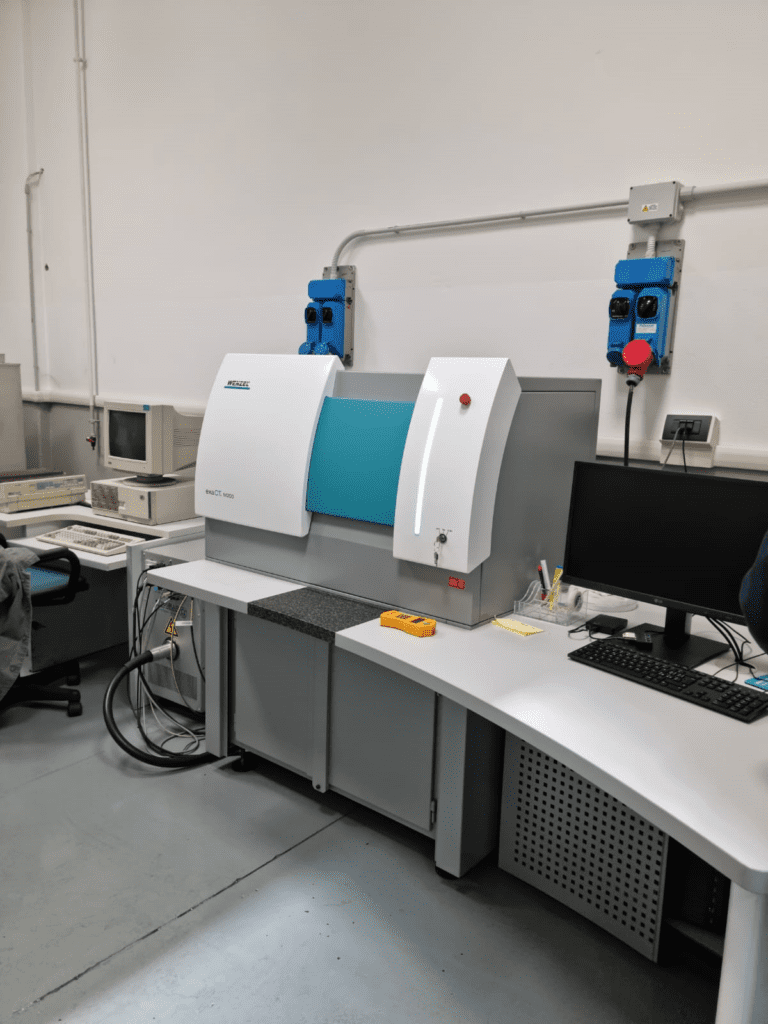

The WENZEL CMM was equipped with a motorized measuring head with a probe for the required tolerances. In addition, four pneumatic stabilizers were mounted as dampers under the granite plate to eliminate the vibrations coming from the production machines. To ensure reliable results the machine was placed in a metrology lab with consistent temperature control.

Let’s take a Peek: Nondestructive testing with computed tomography!

To be able to measure and inspect the internal features of the components non-destructively, the measuring lab was expanded with an industrial computer tomography machine. The exaCT M from WENZEL. The exaCT M is based on a workstation concept that combines high X-ray performance and high scanning speeds with a small footprint. WENZEL’s exaCT M has an integrated evaluation unit in an ergonomic desk workstation that makes it ideal.

WENZEL’s reputation for high-quality machines, efficient measurement solutions, and their strong support team made them the favored choice over its competitors. Above all the interface between the measuring system, machine tools, and robots clinched the deal for Fonderia Bassoli. In the event of a change in production or in the implementation of the measuring program, it is possible to intervene quickly and easily, which is a great advantage.

About FONDERIA BASSOLI

FONDERIA BASSOLI M. S.R.L. is a mining and metals company based in Luzzara, Italy and was founded by Marsilio in 1957. In 1961, his sons Franco and Bruno joined the company, shortly after the first die-casting machine was purchased and technological development began.

In 1989 the company moved into a bigger facility in Luzzara. The company needed more space, thanks to continuous growth. In 1998, they offered a wider range of services with the creation of a new department for the mechanical processing of the castings produced.

To date, Fonderia Bassoli has 22 automatic die-casting cells with variable tonnage from 200 to 1,000 tons, a tooling department with 5 machining centers with 3 to 5 axes, a technical office with 3D software for internal mold design and equipment, and a mechanical machining department with 10 robotic lathes and 3 vertical machining centers. Quality assurance takes place on 8 coordinate measuring machines in process automats. In the metrology lab, there is another coordinate measuring machine with a 3D laser sensor as well as an exaCT M industrial computer tomography machine to see inside the structure of the components.

INDUSTRIAL CT SCANNING MACHINES BY WENZEL

Our Industrial Computed Tomography scanning machines open a whole new world of metrology and offer much more capability than a laser scanner or white light scanning system. Parts and assemblies can now be measured inside as well as outside with the complete part DNA being captured. These CT scanning machines can also be used for material analysis and non-destructive testing.

What distinguishes our CT scanning machines from our competitors is their ease of use by engineers and quality staff not previously experienced in radiography or X-Ray technologies. These systems seamlessly integrate with metrology and other quality applications, are compact and can be safely installed in an office, lab or on the shop floor as part of your quality assurance process.

Contact WENZEL America for more information: [email protected] or visit our website.