Wenzel Inspects Bearings and Ring Gears For Mass Size Objects

- Do you manufacture large objects, but have a difficult time getting measurements right the first time?

- Do you want to improve quality by scanning and get more data points on your parts?

- Did you know that our WGT series of Gear measuring machines can handle loads up to 100,000 lbs.?

- Are you in the market for a robust machine that can handle anything you throw its way?

If you answered, “Yes” to any of these questions, then look no further than Wenzel’s WGT series of Gear measuring machines!

In this design, the CMM measuring arms are each mounted to a table that is in turn mounted on a large corresponding granite base. The measuring arms feature high-accuracy linear guide ways for the X-axis. The Y- and Z-axes feature finely tuned, preloaded roller bearings providing minimum friction and operational wear.

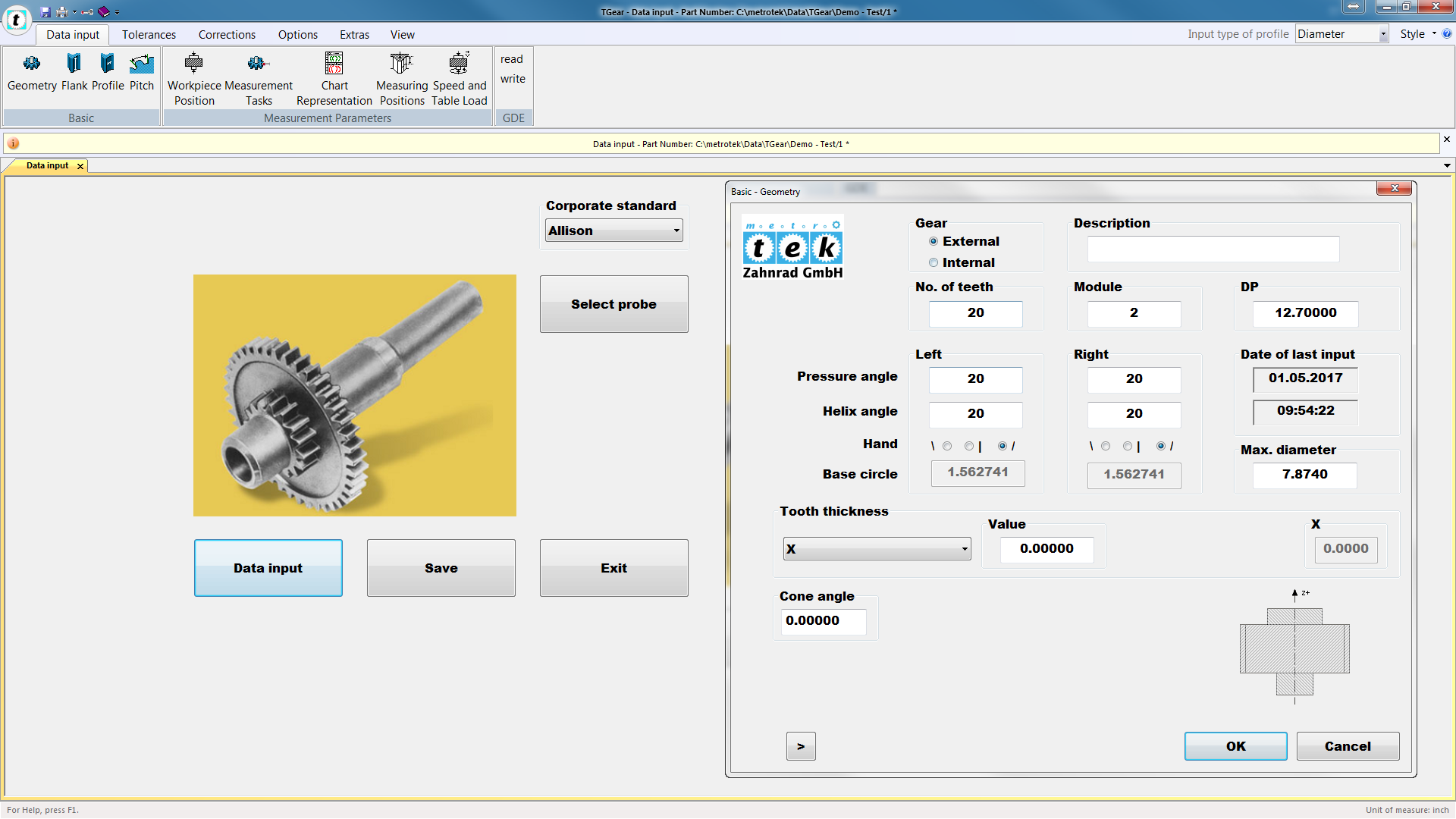

Liebherr Werk Bieberach, GmbH is a German manufacturer of large construction cranes, and was looking for an easy way to measure their cranes – that may be as big as 20 feet in length. Wenzel WGT series of gear measuring machines include application software that helped Liebherr provide a calculation of optimum fitting tolerances for inner and outer bearing components of an object.

Wenzel America offers a wide range of products that will suit every measuring need imaginable! We are constantly developing new technology and ways to use that technology that solves the toughest measurement problems. If you’d like to learn more about our customized gear measuring machines, coordiante measuring machines and innovative measuring technology like computed tomography, optical sensors, laser scanners and 3d scanning services, contact us today!