The Renishaw REVO has been around for more than a decade, measuring everything from automotive engine blocks, to aero engine components, to more recently, additive manufactured components. REVO also makes claim to some pretty impressive capabilities for improving throughput, while maintaining high levels of accuracy. But how does it do that? Is it really possible?

The Renishaw REVO has been around for more than a decade, measuring everything from automotive engine blocks, to aero engine components, to more recently, additive manufactured components. REVO also makes claim to some pretty impressive capabilities for improving throughput, while maintaining high levels of accuracy. But how does it do that? Is it really possible?

Over the next few weeks, I will share with you a series of three posts; first curating some of the available case studies that talk about specific applications and the benefits of REVO, second a close look at what it takes to make an application of REVO successful, and finally some detail on how it fits into your process, and where these productivity gains come from.

You have probably seen claims such as, 80% faster calibration, or 50% faster turbine blade inspection, but where do these stats come from? Are they based on real production metrology examples?

I decided to offer the information up for your interpretation. To keep it fair between OEMs, I used the Renishaw website to deliver you the case studies below. These studies cover applications from turbine blades to power sports, on a variety of CMM makes, one including a retrofit. These wider ranging examples, along with your own knowledge of your processes and metrology needs, should help you make an educated decision on the benefits of REVO for your company.

Click the links below to dive deeper into the studies:

ANT Industries, saw an 83% inspection time reduction

Escribano, up to 80% reduction in time per part

Kawasaki, simplifying programming

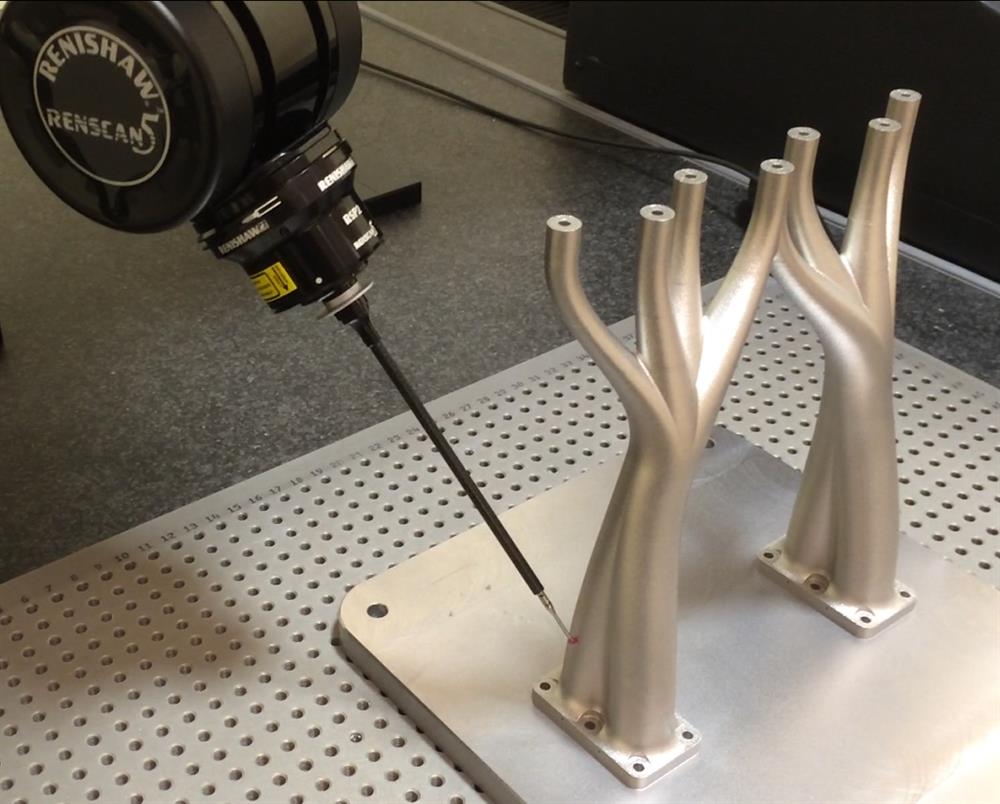

Future AM, validation work taking an hour, down to 10 minutes

TURBOCAM, reduced programming, set-up and measurement time by +50%

In the case studies above, you will find empirical evidence that the REVO is a game changer, regardless of the complexity of the parts or pace of CMM inspection. Whether you are in a high volume automotive environment, or a low volume high-mix job shop, after reading these studies one thing should stand out: The REVO is the most productive investment you can make for your CMM needs.

However, careful planning and implementation are required to make the most of your investment in any new technology, and REVO is no different. In my next post, I will share some insight into the how and who of making REVO successful, to help you capitalize on the capability this 5 Axis technology gives you, and ultimately let you measure #morepartsfaster.