Jet Turbine Engines

Before we can go into detail of the development of jet turbine blades we must first look at where and how everything started.

Global airline flights in 2021 are projected to reach 22.2 million. This is a sharp decline from the projected 40.3 million in 2020, had COVID-19 not happened. These flights are estimated to ferry 2.8 billion passengers. How many of these passengers ever think about the innovation and technology of a jet turbine blade and how the jet engine works?

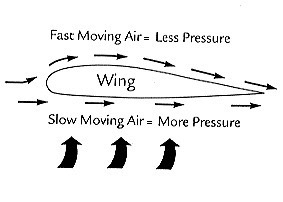

The jet engine is the power plant of today’s jet aircraft, producing not only the thrust that propels the aircraft but also the power that fuels many of the aircraft’s other systems. Jet engines operate according to Newton’s third law of motion, which states that every force acting on a body produces an equal and opposite force. The jet engine works by drawing in some of the air through which the aircraft is moving, compressing it, combining it with fuel and heating it, and finally ejecting the ensuing gas with such force that the plane is propelled forward taking you to your favorite holiday destination or planned business trip.

We will go back in time to look at the history of jet engines, where it all started and how jet turbine blades developed.

The History of Jet Turbine Blades

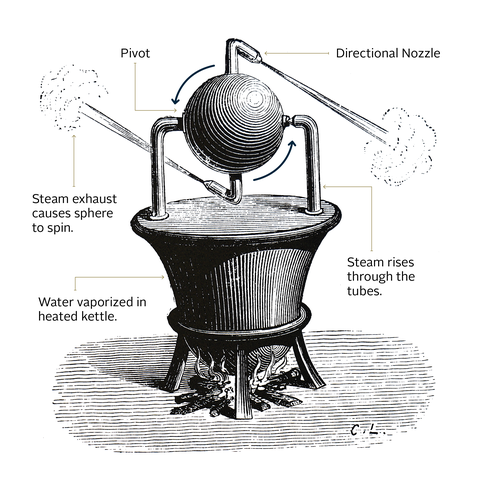

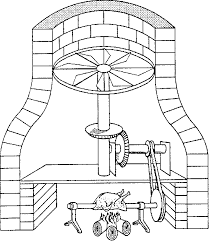

You can go back as far as the Egyptian aeolipile developed 150 BC by Hero from Alexander. The Chinese Rocket technology of the 1230’s, Leonardo Da Vinci’s “Chimney Jack” roasting skewer, Italian engineer Giovanni Branca’s impulse turbine for a stamping mill. Not forgetting Bernoulli’s principle that can also be derived directly from Newtons Second Law of Motion and although all of these did have an impact, it was not till World War I, that it was taken to the next level and amid all the devastation and disruption, it accelerated the rise of aviation and the development of jet turbines that is directly related to the development of the blades.

Breakthroughs and History Makers of the Jet Engine

Swiss engineer Alfred Buchi patented the turbosupercharger in 1910, but the device failed during flight testing in France. General Electric (GE) at that time was primarily focused on building turbines and other equipment for power plants, but in November 1917, the US government wanted to develop its own version of a turbosupercharger and enlisted the company’s help in developing the device for use by the American military.

The task to lead the secret project fell to a GE gas turbine engineer named Sanford Moss.

Moss built a turbosupercharger that used the hot exhaust coming from the aircraft engine to spin a radial turbine of his design and squeeze the air entering the engine, making it as dense as air close to the ground and helping the plane recover its lost power.

The breakthrough happened in 1930 when Royal Air Force Lieutenant, Sir. Frank Whittle submitted a jet propulsion gas turbine patent. His engine, which had a single-stage centrifugal compressor coupled to a single-stage turbine, was successfully bench tested in April 1937 and set the scene for the modern jet turbine engine.

Meanwhile in Germany and entirely separate, Hans von Ohain, while pursuing doctorate work at the University of Gottingen, formulated his theory of jet propulsion in 1933. Von Ohain and Dr. Max Hahn patented a jet propulsion engine in 1936 and on 27 August 1939 in Rostock, Germany history was made with the first ever entirely jet-powered flight.

The aircraft developed 1100 pounds of thrust and propelled the HE-178 to speed of 400 mph (643km/h). The engine used a centrifugal flow compressor. Shortly after the engine developments produced a more advanced turbine engine that incorporated an axial flow compressor that would increase speed to 500 mph (805km/h). In 1942, German Scientist Dr. Franz Anslem developed the axial flow turbojet, the Junkers JUMO 004, which was used in the well-known Messerschmitt ME 262, the world’s first operational jet fighter.

In Germany history was made with the first ever entirely jet-powered flight.

In 1939 the Air Ministry awarded Power Jets Ltd. (a company with which Whittle was associated) a contract to design a flight engine. On 15 May 1941 the Whittle W1 engine made its first flight mounted on the Gloster Model E28/39 aircraft. This aircraft achieved a speed of 370 mph (595km/h) in level flight with 1,000 pounds of thrust. Upon achieving success with the Whittle engine, the British promptly shipped a prototype to their allies in the United States, where General Electric immediately began producing copies. During this time a group of GE engineers called the Hush-Hush Boys designed new parts for the engine, redesigned, tested the engine and delivered a top-secret working prototype called I-A with 1,300 pounds of thrust!

On Oct. 1, 1942, the first American jet plane, the Bell XP-59A, took off from Lake Muroc in California.

The jet age in the U.S. and Europe was in full swing.

It is All About Blades

The jet engine, like many technological innovations, took time to progress from concept to design to execution but two world wars excelled aviation technology. By the end of WW2, modern turbine engine features were introduced including blade cooling, ice prevention, and the variable-area exhaust nozzle.

In 1930 Sir Frank Whittle’s prototypes were made entirely of steel. Steel is great for strength and surface hardness, but when you need high-temperature performance you would look elsewhere because steels limit is 450–500°C.

A key limiting factor in early jet engines was the performance of the materials available for the hot section (combustor and turbine) of the engine. The need for better materials spurred much research in the field of alloys and manufacturing techniques, and that research resulted in a long list of new materials and methods that make modern gas turbines possible.

Aside from material and alloy improvements, a breakthrough was the development of directional solidification (DS) and single crystal (SC) production methods as well as the development of the thermal barrier coatings. Pursuing high performance material, innovative design and improved production methods in the development of blades will be discussed in-depth in next week’s Jet Turbine Blades Part 2 blog. The development over the years and the continues improvement is not possible without measurement.

Manufacturing and Metrology

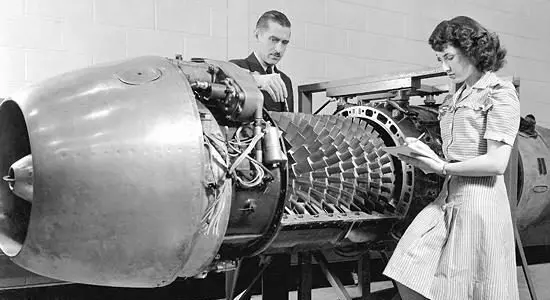

Building and assembling the components of a jet engine takes about two years, after a design and testing period that can take up to five years for each model. Throughout the entire process of building an engine, components and assemblies are inspected for dimensional accuracy, responsible workmanship, and material integrity.

Since 1968 WENZEL’s innovation in metrology have strived to offer better measuring solutions in the manufacturing industry. Turbine blades of different sizes are not an exception to our passion to provide solutions with the latest measuring technology. Their complex curves have critical dimensions that must be measured at numerous places across the blade which limits the reach of conventional tactile systems. Typical measurements include blade cross-sections at several positions and that too has very special challenges. This especially effects the measurement of leading-edge radii, trailing edge radii, root forms, and cooling hole positions and sizes. (*Learn more about turbine and blade functionalities in next weeks blog post.)

Limited by the diameter of the probe stylus, form deviation and defects on small features cannot be detected. A tactile probe has the effect of a mechanical filter on the measurement and can make results appear better or worse than they really are.

Optical measurement systems can be used as an alternative. Reflective surfaces have to be prepared and coated with special powder in many cases. This procedure adds extra material to the part and causes incorrect results for the evaluation of small features. Furthermore, not every method is able to capture small radii or even measure difficult to access features.

WENZEL developed the CORE as the one optical measurement system to fulfill all these requirements. Due to the innovative sensor, there is no preparation of reflective and polished surfaces necessary. Measurement points are captured with a small light spot with a diameter of 35μm. With this measuring system even small radii can be measured in detail with a high number of points and form deviations and defects can be analyzed.

Look how far we’ve come!

The journey of jet turbine blades all started with the determination to go faster and in the next two weeks we will look at the technical aspects and construction of jet turbine blades. Look how far we’ve come in the past six decades. From the first jet in 1939 with a 1100 pounds of thrust to the thrust of a typical jetliner engine with 5,000 lbf (22,000 N) (de Havilland Ghost turbojet) in the 1950s to 115,000 lbf (510,000 N) (General Electric GE90 turbofan) in the 1990s, not to mention a much higher reliability regarding shutdowns per 100,000 engine flight hours.

This, combined with greatly decreased fuel consumption, permitted routine transatlantic flight by twin-engined airliners (ETOPS) by the turn of the century, where previously a similar journey would have required multiple fuel stops.

Today, developments continue in gas turbine technology with new engines offering even greater fuel efficiency and much less noise. Two of the largest gas turbine engines ever built entered service on the Airbus A380 — the Rolls-Royce Trent 900 and the Engine Alliance (GE and Pratt & Whitney partnership) GP 7200. These massive engines produce 70,000 pounds of thrust each.

In the future, it will be interesting to see what is the next phase of gas turbine engine development.

Follow us on your favorite platform and join our series All About Blades, a journey that is not to be missed! Our team and external experts will share more about jet turbine blades, the geometries and challenges in production as well as quality assurance. We look forward to share with you #allaboutblades, especially the Blade Feature Talk!