In continuation of our discussions on “I need to buy a CMM” you’ve spent time answering the “Why?” & “What are you going to measure?” In Part two we will be looking deeper into the needs and goals of why your company will be investing in this valuable asset.

QUICK RECAP OF PART 1

Answering Why?

In I need to buy a CMM you were taking a deep dive into what is driving the investment decision. We made a list of questions for you to answer that will clarify the priorities that drive the decision. Questions like:

- Does the machine have to address throughput issues?

- Reach specific goals?

- Is there requested data that needs to be reported?

These steps are surely obvious to those working on the parts, but it is important to write them down and understand them clearly because this will help with making the right decision when considering which machine you will buy. Answering these questions will help your ROI and justify the investment to the purchasing team/department and final decision-makers.

Recap on answering what?

These questions all speak to the main point of the decision: What are you measuring? Important questions related to size, tolerance, and data requirements must be balanced against your budget, in order to determine the metrology solution that delivers the best possible value for your needs.

WHAT ARE YOU GOING TO MEASURE?

Moving into part 2 we want you to consider “What are you going to measure?” It will be wise to think of both today’s Quality control requirements and future projects that may bring new requirements. This could mean requirements 5 years from now! When making the investment in a CMM you want it to meet your needs for both today, tomorrow, and the future.

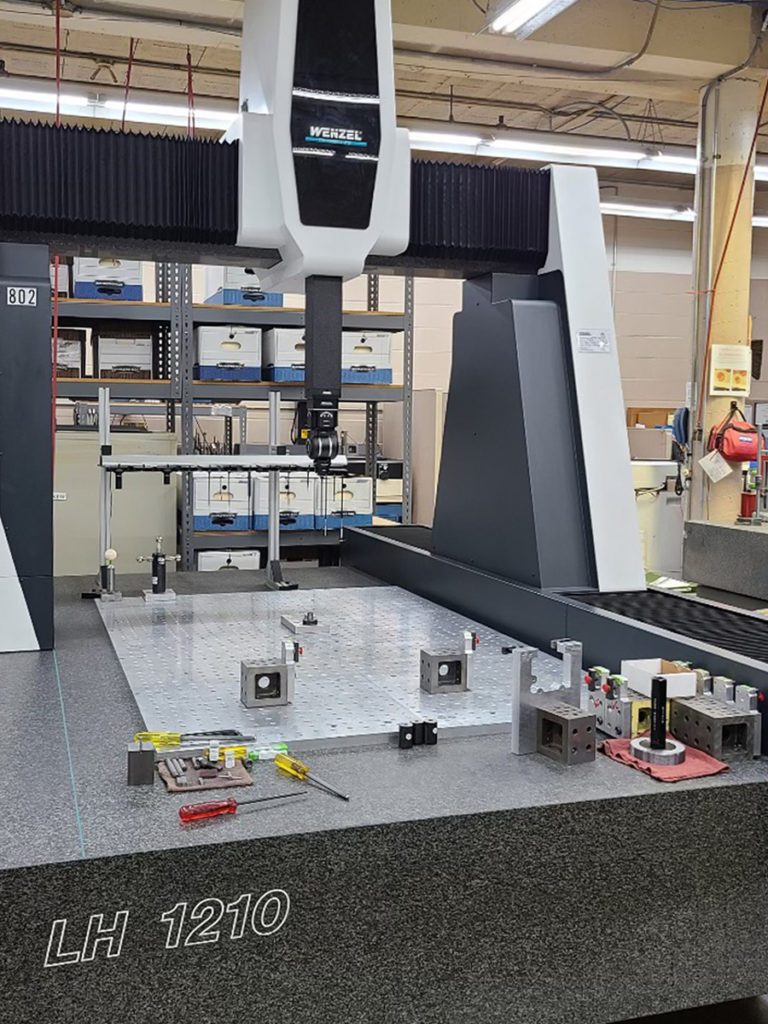

When considering future projects, there are many ways to take this into consideration. One option is to increase the overall size of the machine you plan to purchase. For example, if your data showed a 1200 x 2000 x 1000 mm would be the correct size for your current requirements. By considering future growth and throughput, you might consider increasing to 1200 x 3000 x 1000mm.

With the larger size, you could have multiple part setups, called, palletizing, in the volume of the WENZEL CMM. Palletizing parts ensures flexibility to measure in sequence, making it easy and efficient.

THE QUICK SELECTION TABLE

With a big surface to measure more parts faster through palletizing do not forget about WENZEL’s QUARTIS Metrology software! QUARTIS has a unique feature where you do not have to inspect all like components, they can be various parts too. QUARTIS software offers you the quick selection table. One of the options is a “batch recorder” where you can record the sequence in which you want various parts measured. This option helps optimize your throughput with fewer errors and less operator intervention. It is an one click-and-go process. (Check out this cool video with our partner Christian Klostermann)

WENZEL machines often have a service life of over 20+ years which is wonderful when considering offsetting the cost against multiple years instead of a single project.

INSPECTING AVIATION PARTS

Let’s look at measuring a specific part and what that would entail. When inspecting aviation parts, you are probably thinking ”aerospace CMM”. The truth is, there is no such thing as an aerospace-specific CMM or even an automotive CMM. A CMM can measure anything in any industry! A CMM is not specified by a specific industry. The CMM system you choose will be the system you use in your industry. You want to make sure you choose the system that would optimize your measuring process no matter the size or complexity of your parts, products, or workpieces.

In aerospace when you need to measure big parts specifically you would most probably consider a bridge-style CMM. For smaller workpieces, WENZEL has other options like the XO and LH CMMs that work excellently. Then when looking at highly polished surfaces and blades our CORE D, is like the blade master of WENZEL measuring blades at the speed of light.

Visit our website Product Finder, a tool that will help you decide what CMM best fits your need.

WENZEL is also known in the field of medical developments, prostheses, the food industry,

and electric vehicle innovations.

At the end, no matter what size the workpiece is you want to measure remember that our WENZEL CMM has an all-granite construction which differentiates us from many other metrology manufacturers. This is essential for the homogeneousness of the entire structure that allows for greater accuracy.

THE FINAL TOUCH

The Sensor is the final piece of the puzzle to get the most accuracy, and flexibility out of the investment you have made. Adding a Renishaw sensor to your WENZEL CMM of choice makes it the perfect package!

No matter how complex or simple your workpiece is, the Renishaw PH10 indexing head with the SP25 scanning probe can be just the solution. You could consider the Renishaw PH10 indexing head with the SP25 scanning probe. Or if your budget allows the Renishaw REVO with its innovative technology. 5 Axis probing enables the stylus to follow a continuous path around complex components without having to leave the surface to change the stylus cluster or index the head. The system is an articulating head that moves in two rotary axes as it measures. It uses the synchronized motion of the CMM and the head axes to minimize the machines’ dynamic errors at ultra-high measuring speeds which allows for better accuracy. Without a doubt, the REVO offers infinite-position, 5-axis scanning, and eliminates time-consuming tasks, and can take 4000 points per sec.

THE DECISION IS MADE!

WENZEL’s representatives spend quality time with each client to discuss the types of parts that will be inspected. During the process it is very important to define your needs, the priorities and the requirements. This ensures WENZEL knows exactly what you want to accomplish and how to optimally assist you in choosing the machine that delivers over and above your expectations.

You have made your decision to work with a flexible partner. A partner that listens to your needs and devises a tailor-made solution to reach your goals. WENZEL offers a variety of frames with the versatility of different sensor packages that compliments the accuracy you need. This together with the right software package is the recipe for success in measuring more parts faster every time.

More about the Author: Chrysee Bollon has been with WENZEL America over 5 years as a Regional Sales Manager and have been in the Metrology industry for many many years. Please do not hesitate to email her at [email protected] if you have any questions.