CORE S

CORE S is a 5-axis, optical CMM system ideal for measurement of small to medium turbine blades, medical implants or any parts with polished, reflective surfaces and sharp edges.

GT Series 1200

Components for large scale machines from the field of machinery and plant engineering need a suitable gear measuring machine. The GT 1200 is the largest measuring machine of the series, making an easy loading of heavy parts possible.

GT Series 900

Whenever engine components for aviation or smaller marine gear units need to be measured, GT 900 is the ideal gear measuring machine. It is equipped with a movable tailstock—allowing this machine to be loaded easily.

GT Series 650

Due to the maximum measurable diameter of 650 mm, the GT 650 is especially well suitable for the analysis of geared parts and shafts used in commercial vehicles, rail transmissions or construction and agricultural machinery.

GT Series 450

The GT 450 gear measuring machine is typically used in the aerospace, automotive and their supplier industries. It allows the precise analysis of gears and rotationally symmetrical parts up to a diameter of 450 mm.

GT Series 300

The GT 300 was especially developed for the measurement and analysis of smaller gears and rotational symmetrical parts from the automotive industry. Optionally the GT 300 can be equipped with a tailstock for measurements between centers.

exaCT U

The exaCT U is the new generation of industrial computed tomography. This machine can be used universally and is designed in such a way that each customer can tailor his individual system with the appropriate X-ray source and detector. Precise measurements can also be generated after a short training period.

exaCT M

The integrated desk on the exaCT M serves as a workspace for measurement and data analysis forming a perfectly designed, ergonomic workstation. Software, service, consultation and training are also integrated. This machine is top performing and the integrated application software is very user friendly.

exaCT S

The exaCT S is a modular system concept with exceptional system stability and can be perfectly integrated into existing measurement rooms. The compact size of the system associated with precision mechanics and the innovative detector technology are the foundation for the systems excellent stability.

CORE M

CORE M is a 6-axis, optical CMM system ideal for measurement of medium to the largest turbine or fan blades or any other parts with polished, reflective surfaces and sharp edges.

R-Series

The RS is a good-value, mechanical bearing, Horizontal Arm CMM, side mounted onto an inherently stable base plate. This system generally does not need a foundation so can be easily installed into an existing room.

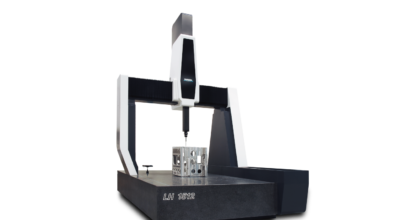

LHF

A traveling Bridge CMM designed specifically for the most challenging work pieces. Ideal for inspection of maritime powertrain, aerospace frames and landing gear.

LH Gantry

LH Gantry combines the accuracy of a Bridge CMM with top coordinate measuring volume. These machines are ideal for large, heavy, tight tolerance machined parts and tooling.

XOrbit CMM

An entry level, top-quality version of our CMMs. This machine brings the renowned stability of a granite CMM to the entry level market, in a variety of sizes and configurations.

LH Compact CMM

The precision you require in a compact sized machine. Whether you need an entry level machine or a machine with greater emphasis on performance—our products will exceed your expectations.

SF 87

The new SF 87 Coordinate Measuring Machine is the universal measuring machine for the production environment. The SF 87 requires little floor space and is ideal for a large part of the metal cutting and forming industry.

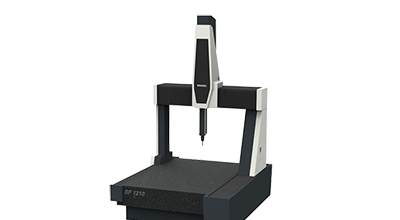

SF 1210

The new coordinate measuring machine SF 1210 is WENZEL’s answer to the trend to bring metrology closer to production. The SF 1210 offers a large measuring volume of 1200 x 1500 x 1000 mm.

LH Large CMM

The Large LH CMM is the latest in high-performance Bridge style CMMs. The Large LH CMM combines the legacy of the LH CMM with a modern look, as well as the latest in sensor technology.

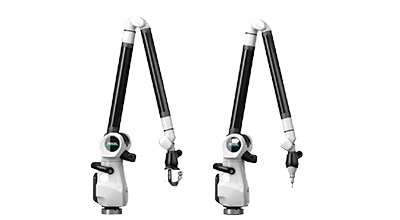

WM | MMA Series Mobile 7-Axis

By combining a portable 7-axis measuring arm with a high-resolution line scanner, which captures every detail contact-free, the measuring arms represent a useful complement to your established classical coordinate measuring systems.